Polyurethane railway track bed and its production method and application

A polyurethane and polyurethane layer technology, applied in the field of polyurethane, can solve problems such as hidden dangers of railway transportation, shorten the maintenance period of ballast bed, and reduce physical and mechanical properties, and achieve the effects of improving service life and reducing vibration and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

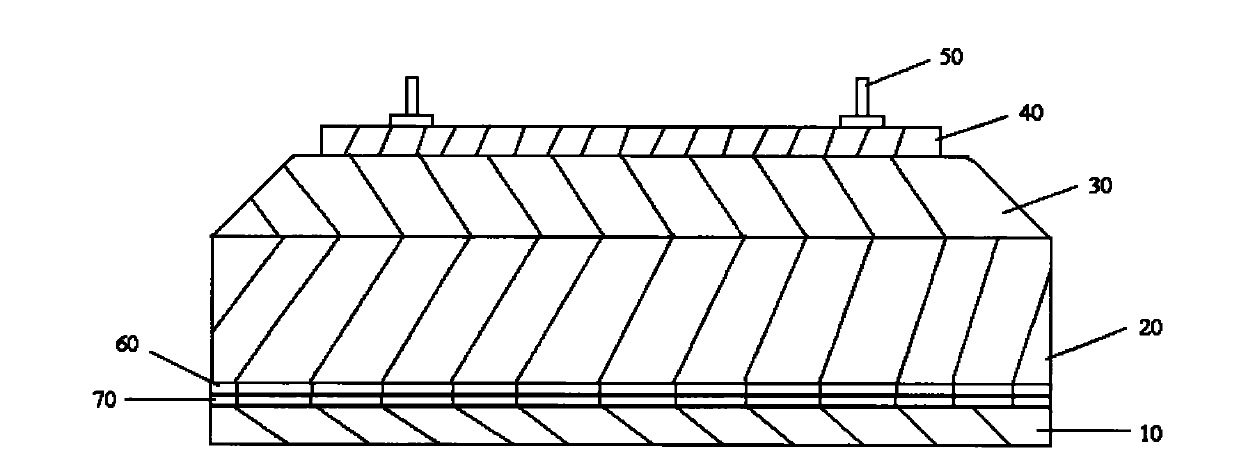

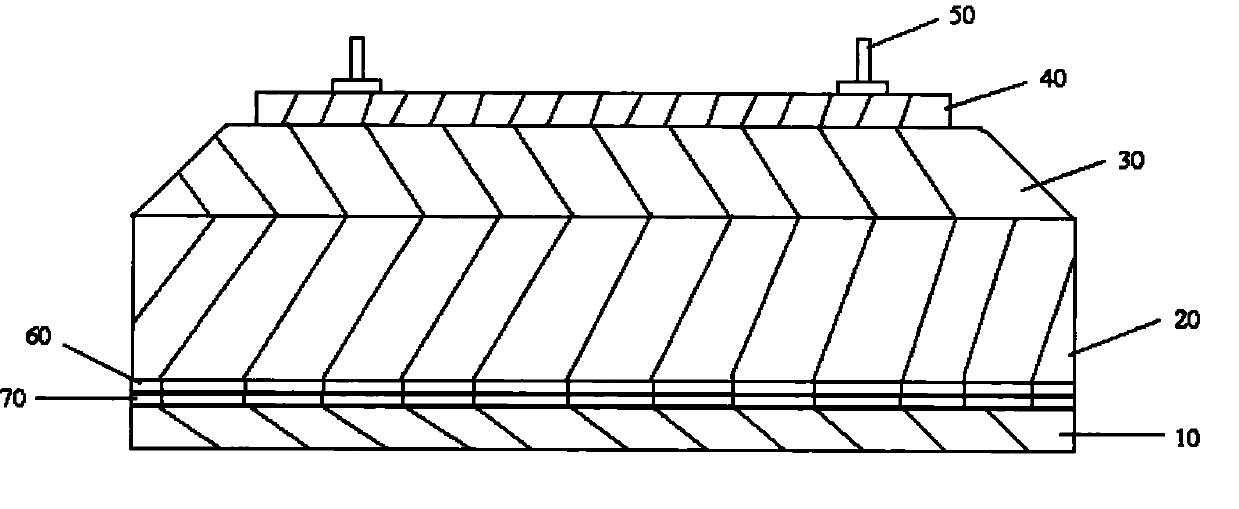

[0049] According to the method for preparing polyurethane railway track bed provided by the present invention, an appropriate amount of ballast is put into the mold, and the ballast is compacted with a vibrator or a press until the relevant requirements of the railway ballasted track are met, and then the first reaction system is poured into the mold In, reaction, foaming, curing and molding to obtain a molded polyurethane layer.

[0050] The mold may be a mold used in the prior art for preparing molded polyurethane, and the material of the mold is preferably but not limited to metal and epoxy resin.

[0051] The first reaction system, see first reaction system .

[0052] Before pouring the first reaction system into the mould, a drainage mat and / or ballast mat with a thickness of 2-30 mm can also be laid on the bottom of the mould.

[0053] The drainage mat and / or ballast mat is preferably but not limited to rubber-based granular pressure-bonded material, rubber-based stri...

Embodiment 1

[0134] Use the HK 1250 conventional high-pressure pouring machine to inject the components Desmodur18IF19 and Bayflex 12BX012 of the first reaction system into a mold with ballast, drainage pads and structural reinforcement materials according to the dosage listed in Table 1-1 (mold temperature 35- 50°C), react, foam, and cure to form a molded polyurethane layer. The physical and mechanical properties of the obtained molded polyurethane layer are listed in Table 1-1.

[0135] Table 1-1

[0136]

[0137] Example 1 illustrates that the hardness and rigidity of the molded polyurethane layer prepared according to the method provided by the present invention are relatively high. Foam density over 400kg / m 3 The molded polyurethane track bed can be used as a transition section between high rigidity ballastless track bed and low stiffness ballasted track bed, or directly applied to ballasted track polyurethane molded track bed.

Embodiment 2

[0139] Use PU20J-R / Y conventional low-pressure injection machine to inject the first reaction system with the ingredients and dosage listed in Table 2-1 into a mold with ballast, drainage pad, and structural reinforcement materials (mold temperature: 35-50°C) , react, foam, and cure to form a molded polyurethane layer. The physical and mechanical properties of the obtained molded polyurethane layer are listed in Table 2-1.

[0140] table 2-1

[0141]

[0142]

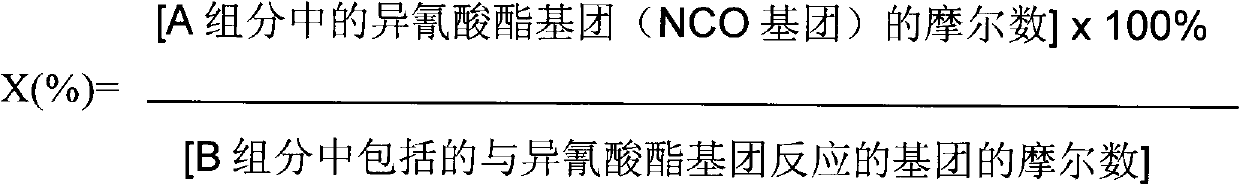

[0143] Example 2 illustrates that the hardness and stiffness of the molded polyurethane track bed can be changed by changing the amount of the isocyanate component, so as to be suitable for the actual needs of different types of railway track beds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com