Construction apparatus of double-block ballastless track and construction process

A ballastless track, double-block technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of slow construction progress, occupying a lot of equipment, complicated construction technology, etc., and achieve accurate and reliable sleeper spacing and high equipment utilization rate , The effect of simplifying the operation procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0068] (1) Construction equipment for a double-block ballastless track of the present invention

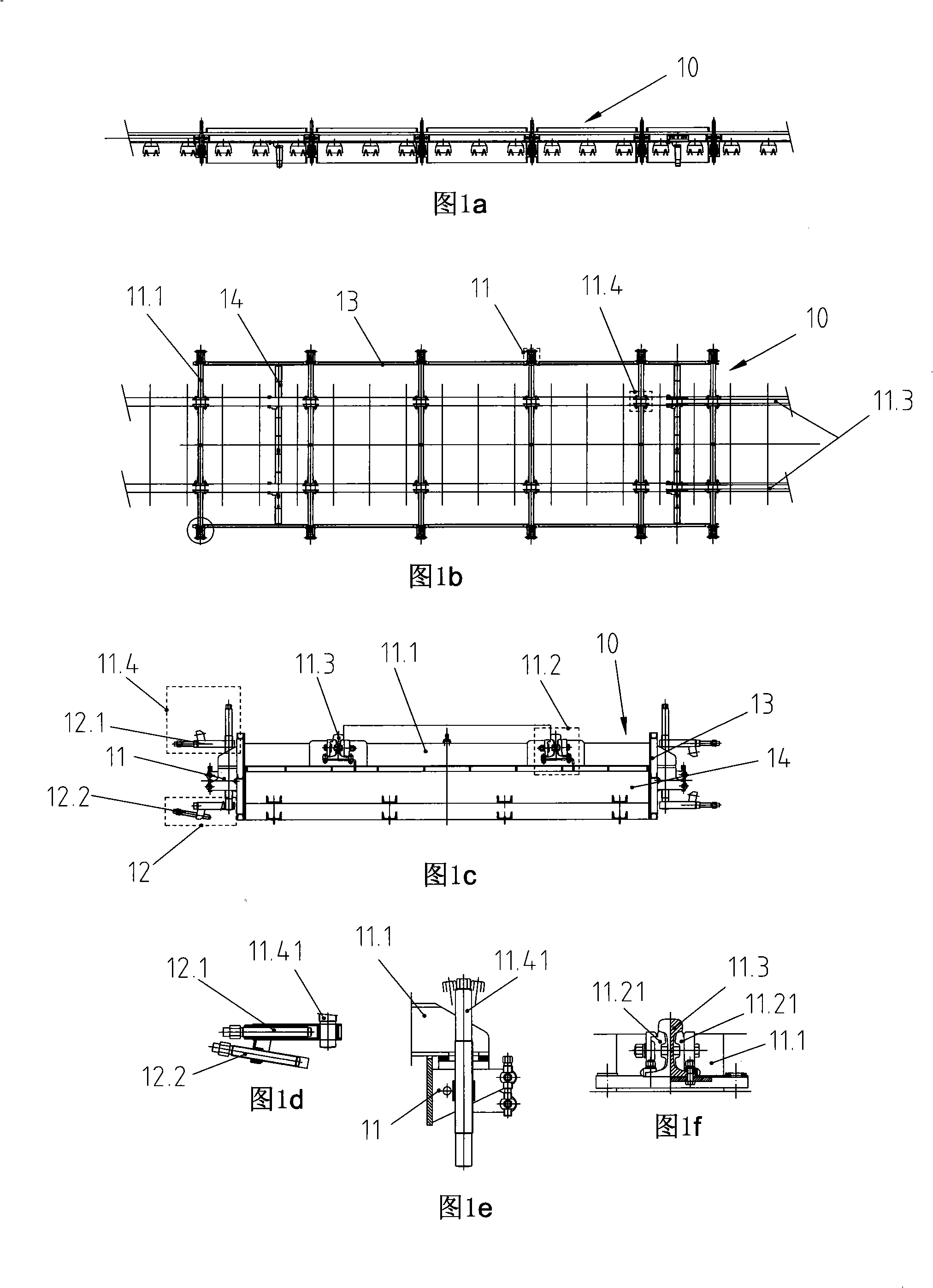

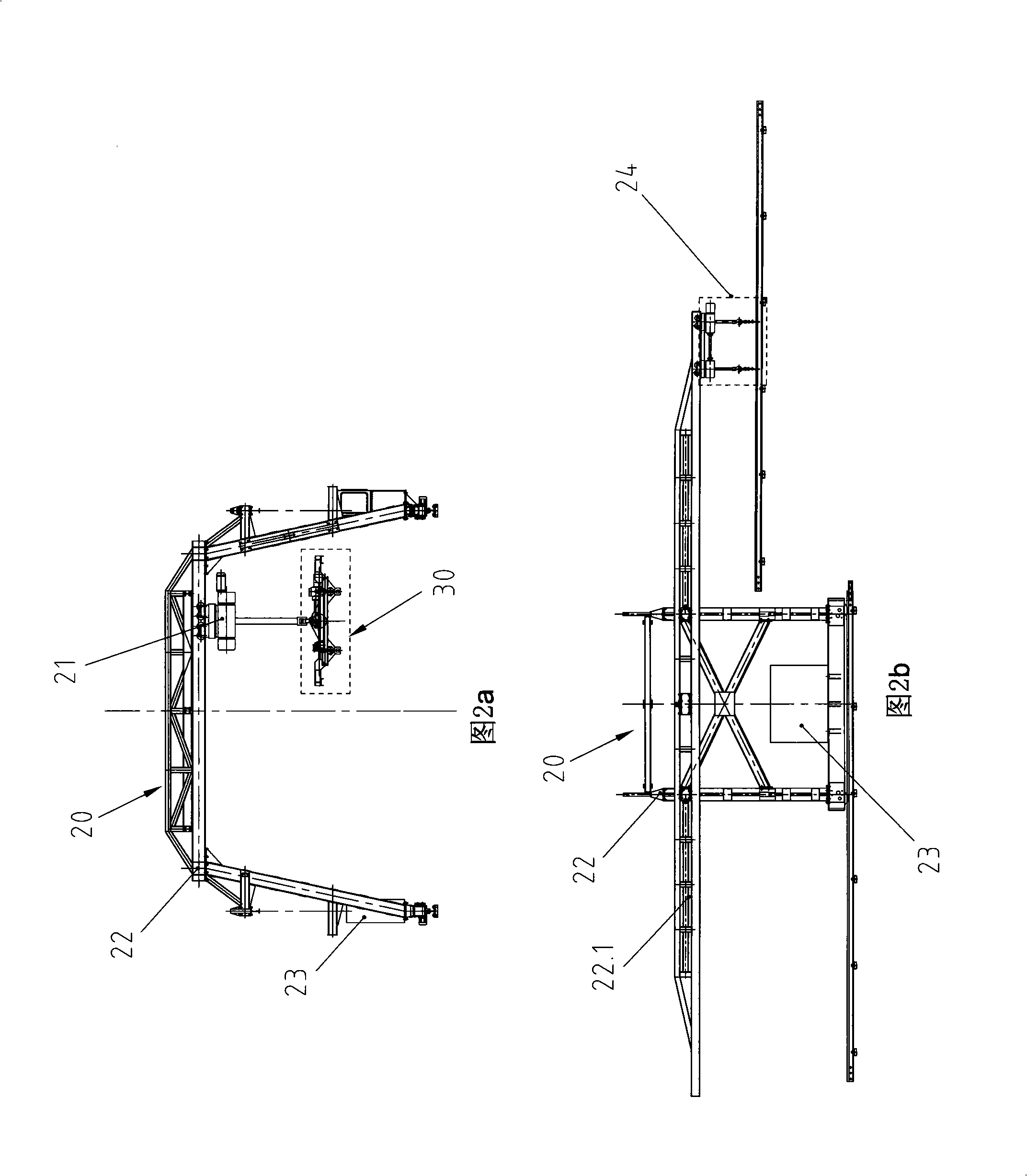

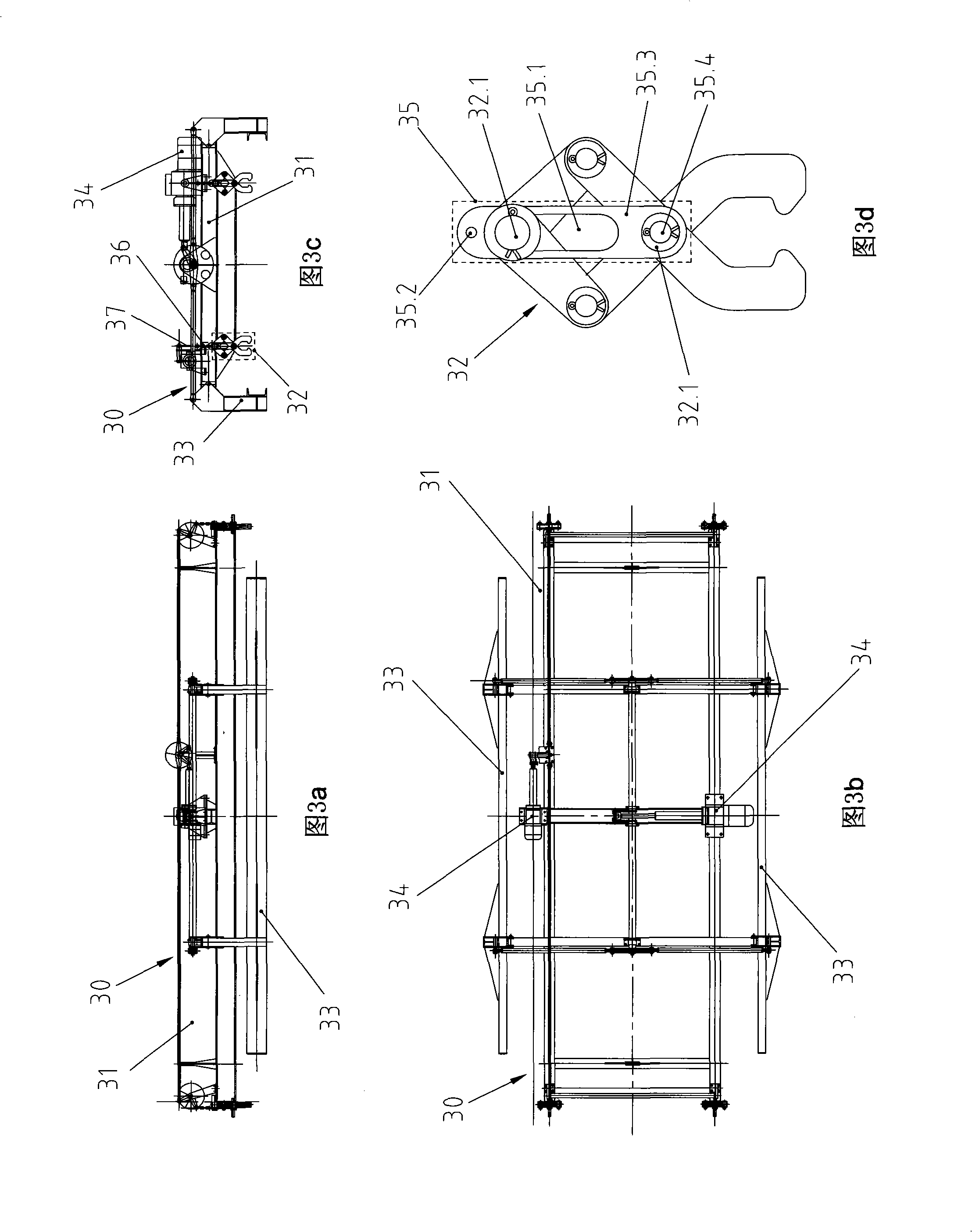

[0069] The construction equipment for a double-block ballastless track as shown in Figure 1-6 includes a combined track bent frame 10 used in conjunction with each other, a self-propelled paving machine 20, a multifunctional electric control spreader 30, and a mobile machine Divide the sleeper assembly platform 40 and the shunting flat swing bridge 50.

[0070] The combined rail bent frame 10 shown in Figures 1a, 1b and 1c is used for sleeper installation and positioning, installation templates and track rough adjustment and fine adjustment, including rail row frame, bent frame legs 11, rail direction locker 12, Vertical template 13 and horizontal template 14. Referring to Fig. 1c, the rail row fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com