Metro shock absorption and vibration isolation elastic mixed light track bed

An elastic and ballast bed technology, applied to roads, tracks, ballast layers, etc., can solve problems such as many weak soil layers, short service life, and complex physical and mechanical properties of soil layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

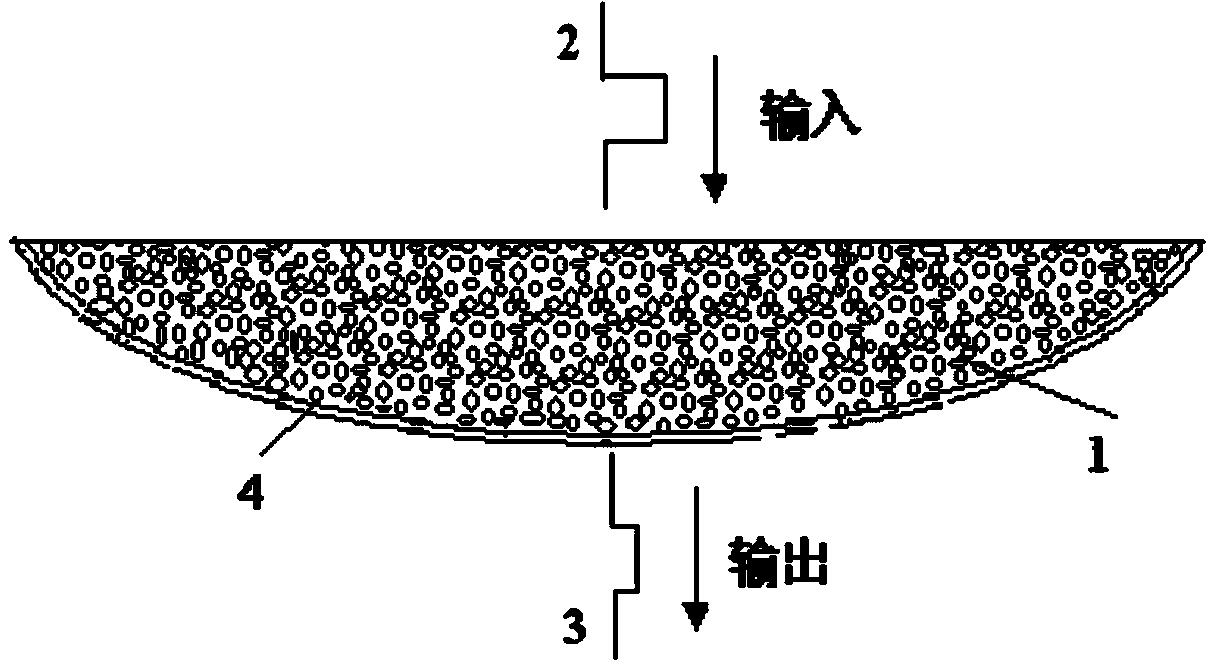

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] like figure 1 Shown is a subway shock-absorbing vibration-isolation elastic hybrid lightweight track bed, including an elastic lightweight concrete layer, the elastic lightweight concrete layer is arranged at the bottom of the subway track bed as the foundation track bed 1, and the base track bed 1 is connected with the subway lining pipe The sheets 4 are in contact with each other, and the thickness of the basic ballast bed is 25-30±cm.

[0024] The base layer of subway elastic mixed light track bed is mainly made of concrete-EPS particles, which can absorb the vibration waves and vibration energy generated by the running of subway locomotives, which can effectively block and reduce the transmission of locomotive vibration energy to the lining structure of the subway, and It is transmitted from the lining structure to the surrounding rock and soil, causing add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com