Tension-compression elastic support

An elastic bearing and bearing technology, applied in bridge parts, bridges, buildings, etc., can solve problems such as excessive local stress in bridge structures, and achieve the effects of good market prospects, reasonable structural stress and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

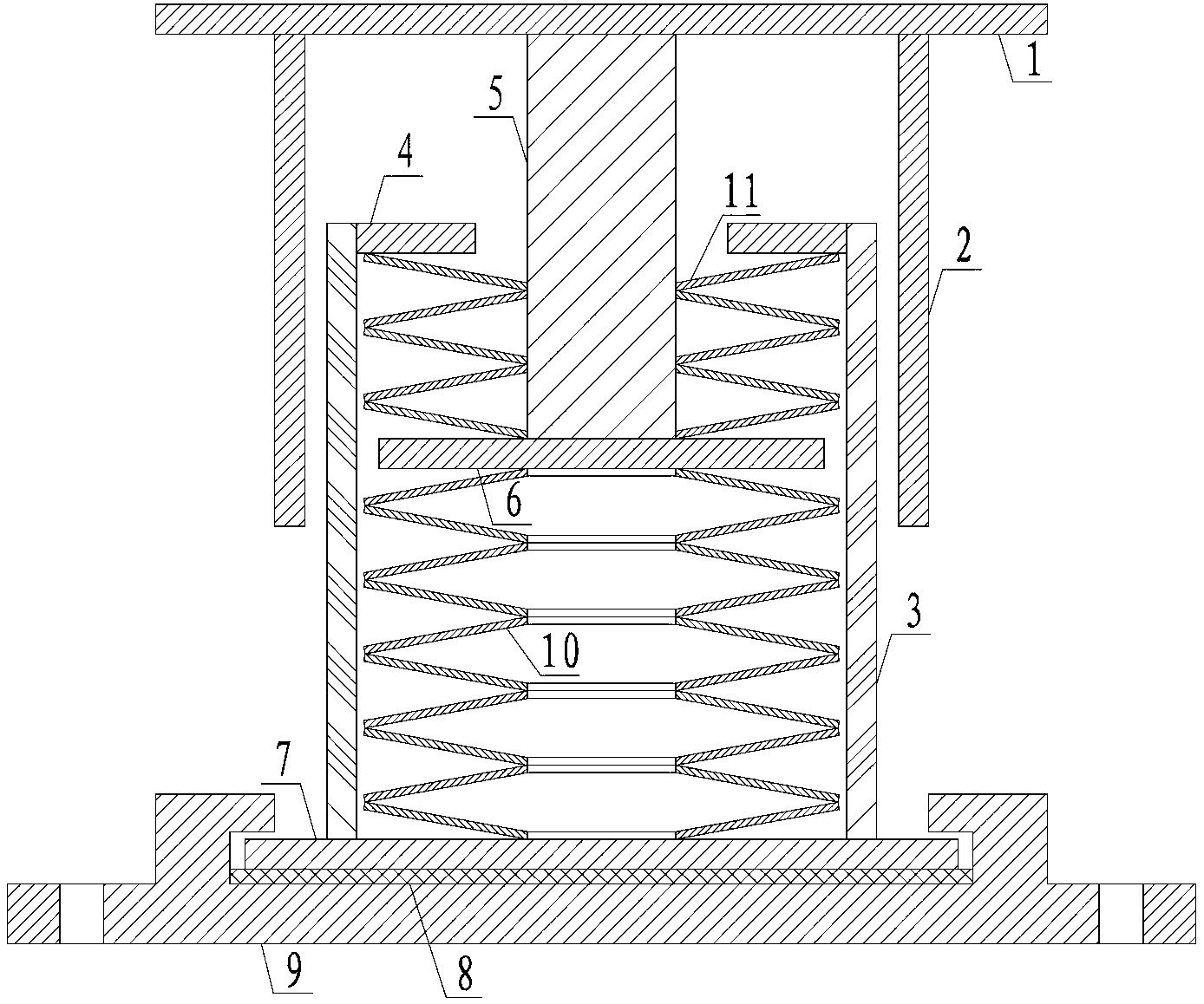

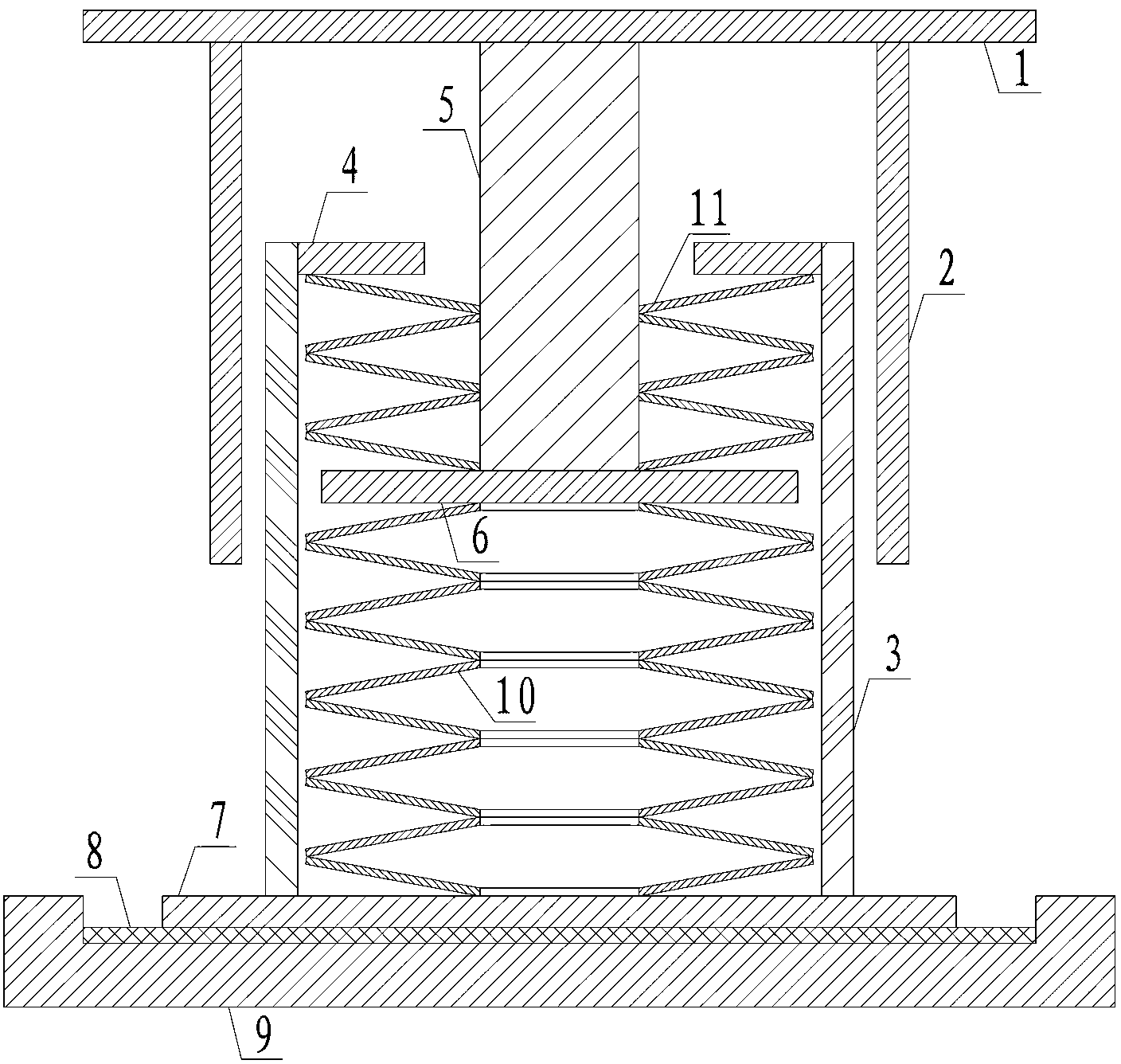

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions (and accompanying drawings).

[0017] The support top plate 1 of the tension-compression spring is fixedly connected with the bridge superstructure. If the bridge superstructure is a steel structure, it can be directly welded. If the bridge superstructure is a concrete structure, it can be connected with bolts. The support bottom plate 9 is fixedly connected with the bridge substructure by bolts.

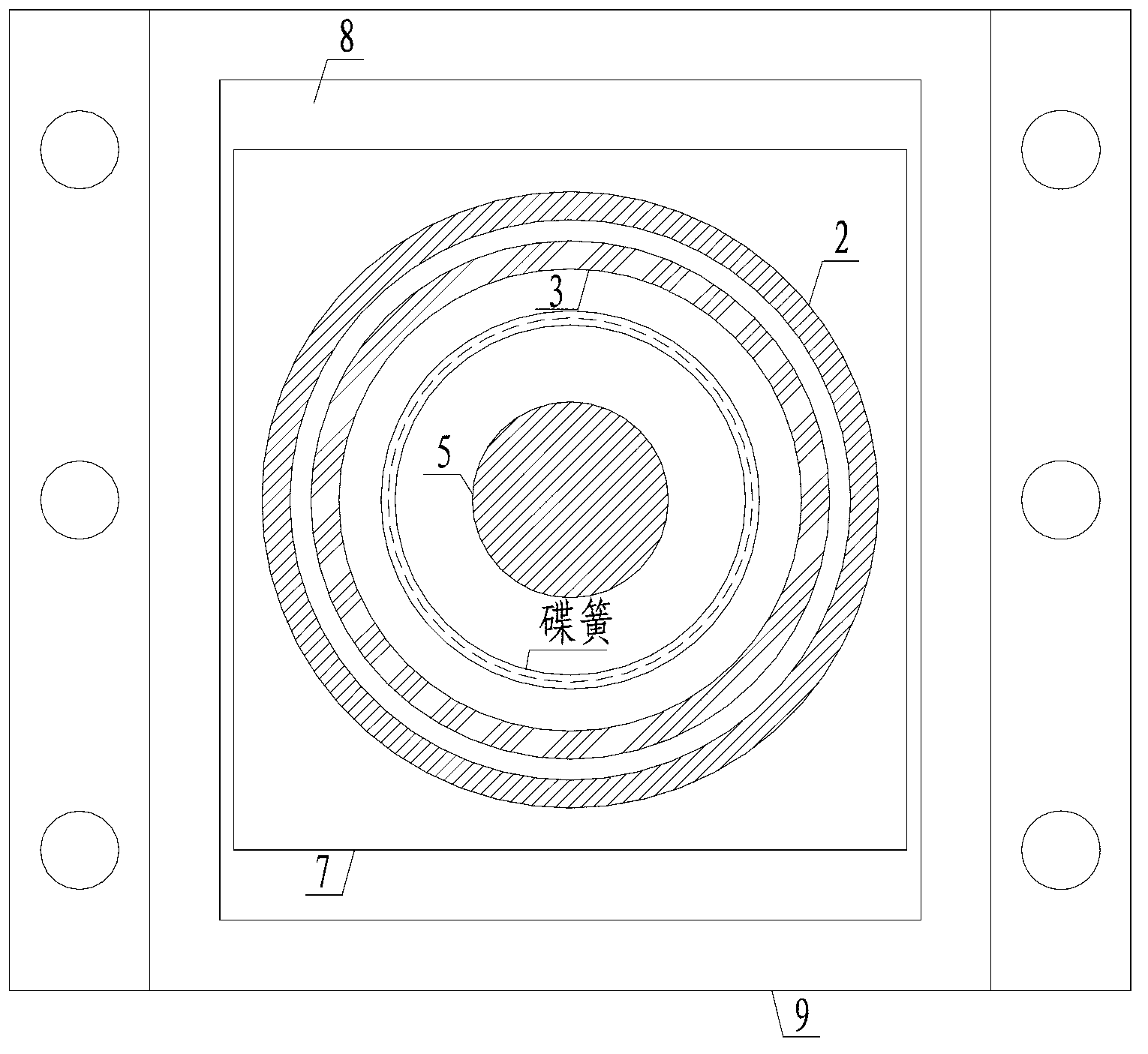

[0018] The outer casing 2 is set outside the inner casing 3, and the disc spring group is placed in the inner casing 3, and the inner casing 3 is connected with the annular baffle 4 and the steel slide plate 7, which jointly protect the disc spring group and fix it. The role of the position, the size of the inner casing 3 is determined by the outer diameter of the selected disc spring, and then the size of the outer casing 2 is determined by the size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com