Synchronous gearless permanent-magnet draw machine

A synchronous traction machine and gearless technology, which is applied in the field of traction machines, can solve the problems of low concentricity, affecting the braking effect, and increasing the structural size of the whole machine, so as to achieve high reliability and manufacturability, and improve the air gap The effect of magnetic field waveform and small overall structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

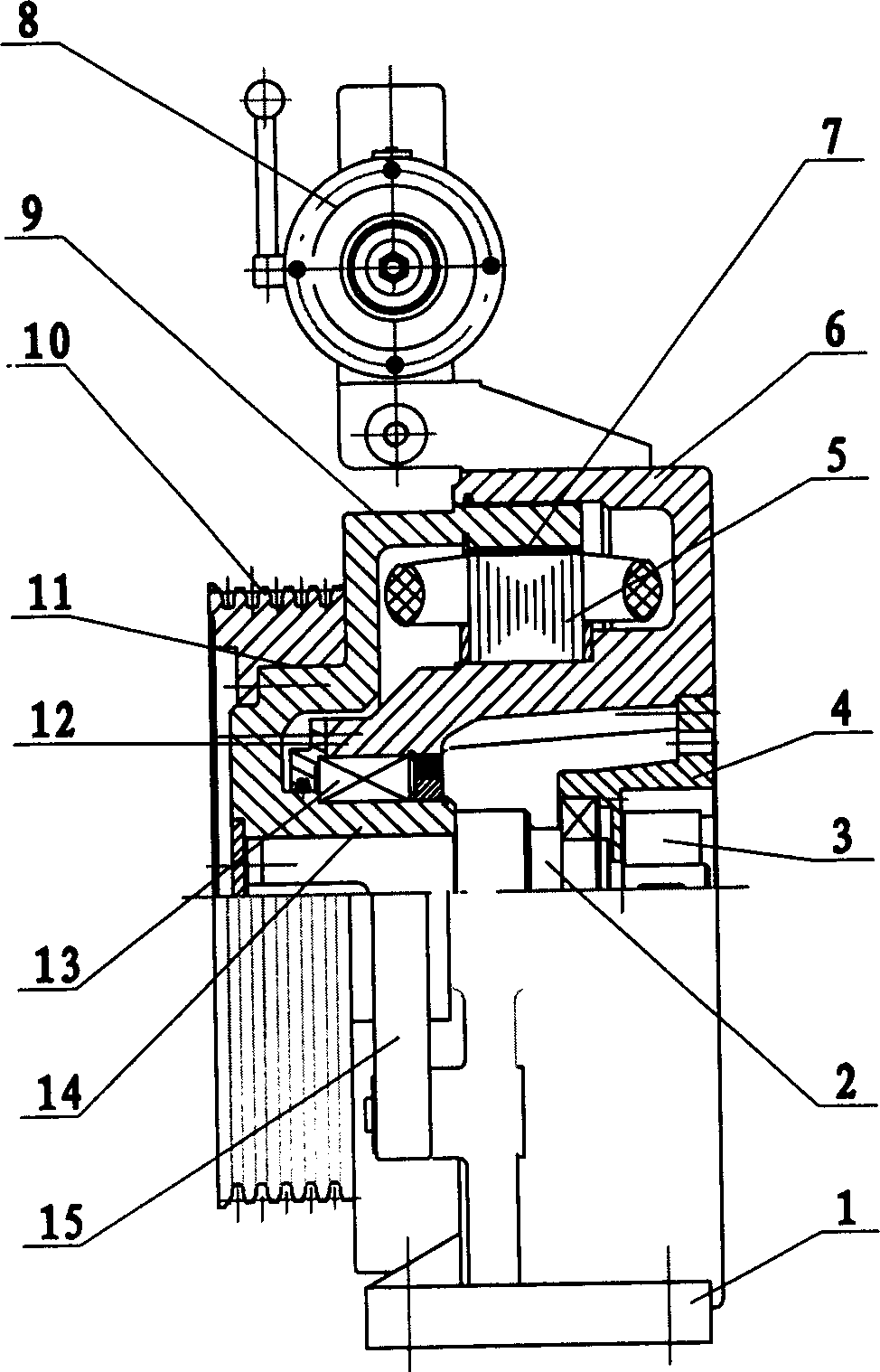

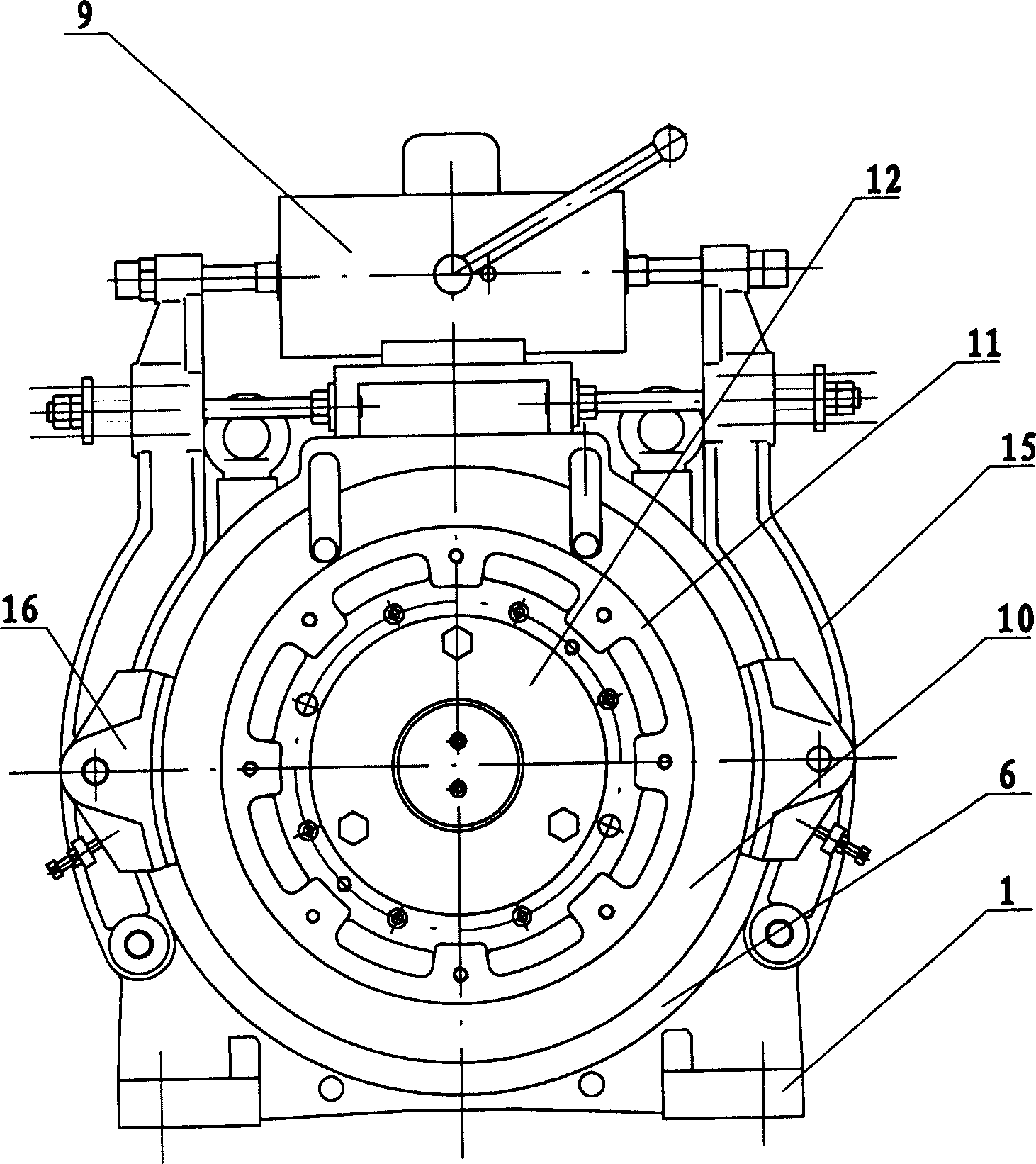

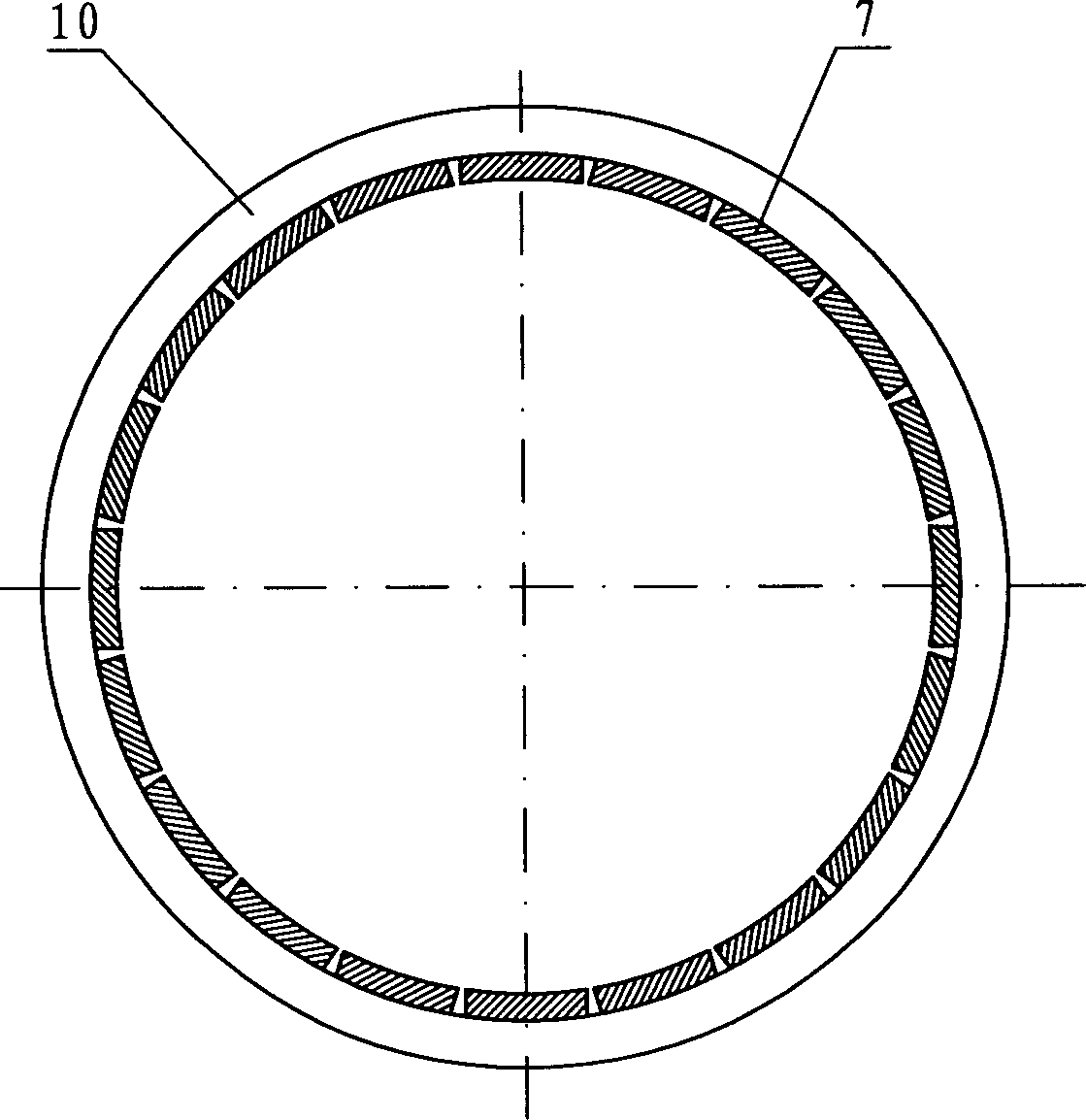

[0027] according to Figure 1-3 The specific structure of the present invention will be described in detail. The device includes a stator, a rotor and a braking device, wherein the machine base 1 is integrally cast with the stator shell 6 and the support sleeve 12, and its specification and shape should be determined according to specific application requirements. The outer peripheral wall 9 of the rotor, the end shoulder 11, and the axle sleeve 14 are cast as a whole. Similarly, its specification and shape should also be determined according to specific use requirements. The inner side of the outer peripheral wall 9 of the rotor is pasted with equal-radius parallel magnetized arc-shaped permanent magnets 7, and its pole arc coefficient is 0.75-0.95. One end of the rotating shaft 2 is fixed in the shaft hole of the rotor shaft sleeve 14, and the other end is assembled in the bearing sleeve 4 by means of a bearing. The stator core 5 is press-fitted on the outer periphery of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com