Fabricated steel-profiled steel sheet concrete combined board small box girder

A technology of profiled steel plate and concrete, applied in bridges, buildings, etc., can solve problems such as long construction time, achieve the effects of shortening construction time, ensuring production quality, improving effective prestress and resisting shear buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

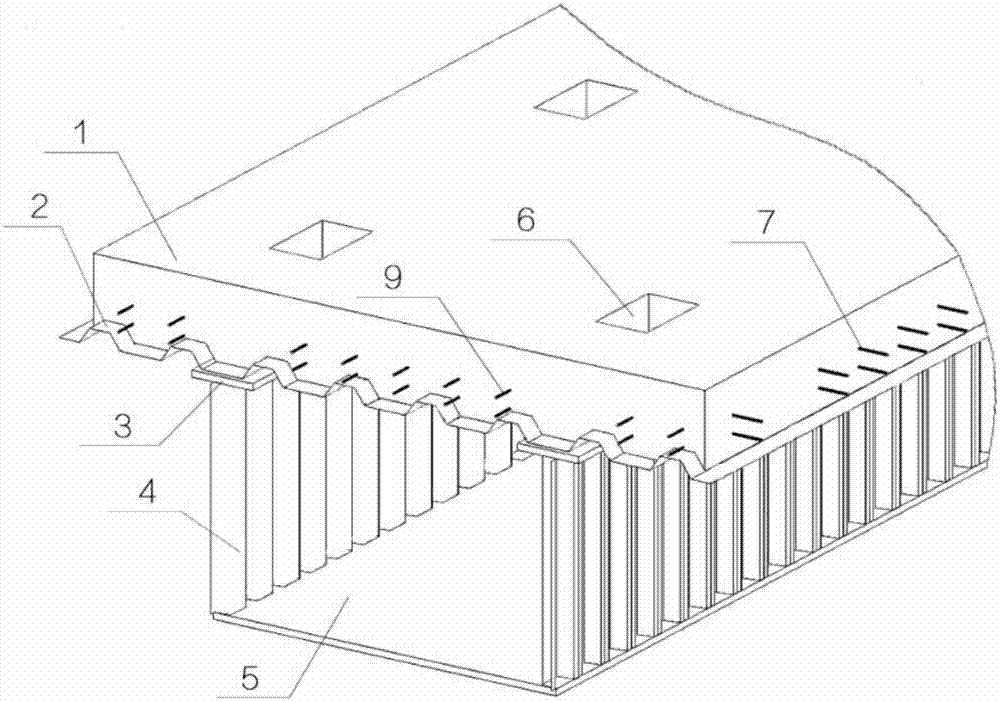

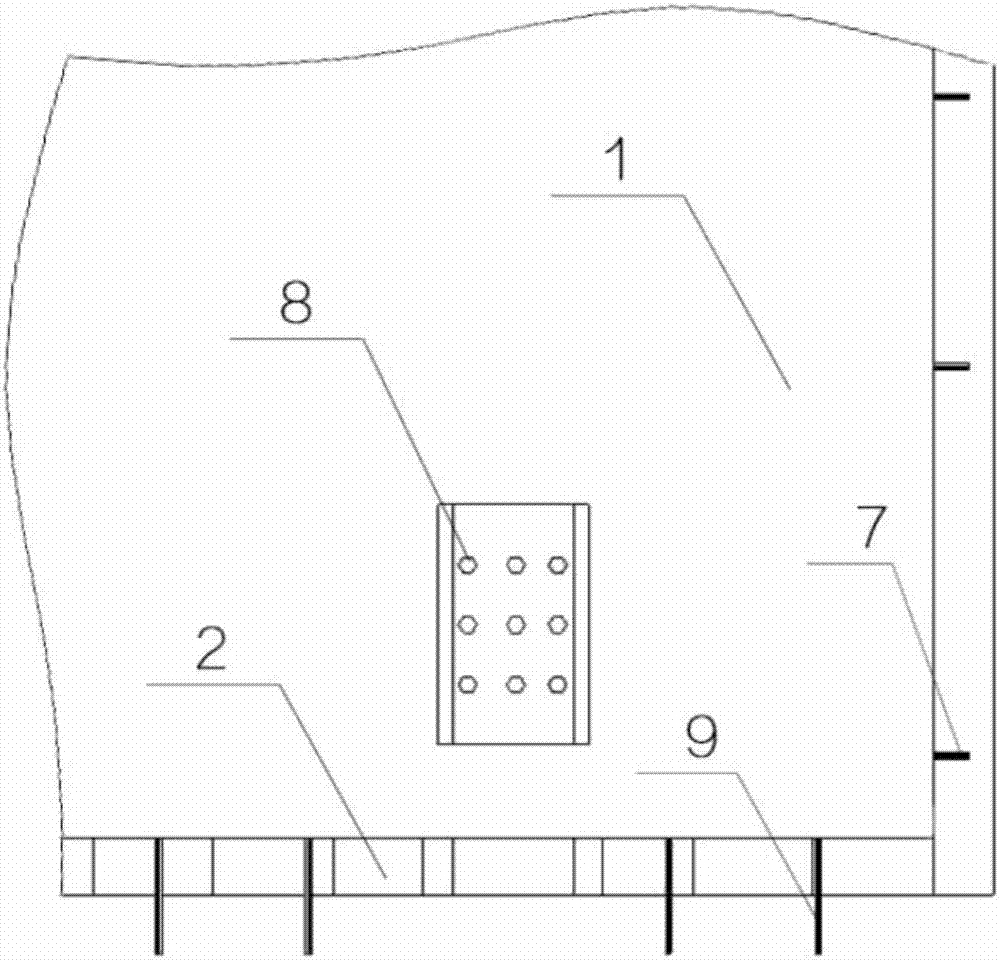

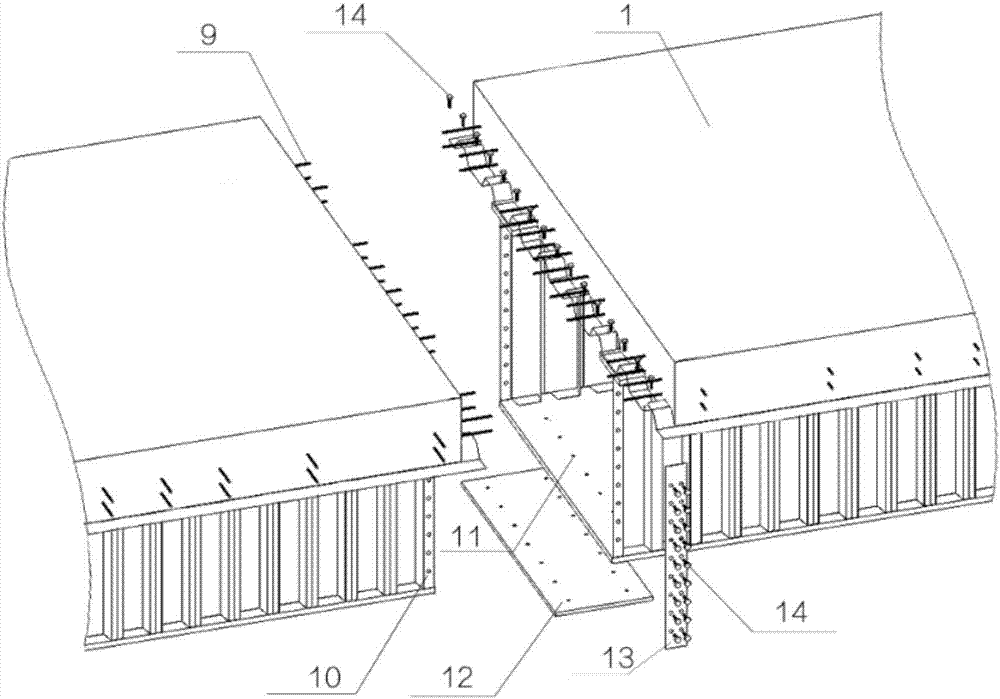

[0015] Specific implementation mode 1: The small box girder of the assembled steel-profiled steel plate concrete composite slab in this embodiment includes a steel box and a profiled steel plate concrete composite bridge deck, and the steel box is composed of a steel bottom plate 5 and two corrugated steel webs 4 , two corrugated steel webs 4 are welded on the plate surface of the steel bottom plate 5 to form a rectangular box structure, and an upper steel support 3 is arranged on the upper edge end surface of each corrugated steel web 4, and the upper steel support 3 and the corrugated The steel webs 4 are perpendicular to each other, and a profiled steel plate concrete composite bridge deck is arranged on the two upper steel brackets 3, and the profiled steel plate concrete composite bridge deck is prefabricated by pouring concrete on the profiled steel plate 2 with steel mesh , the reinforcement mesh is welded by transverse steel bars 7 and longitudinal steel bars 9 at the i...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that the corrugated web 4 has a uniform or non-uniform periodically repeated waveform, and the waveform section is trapezoidal or sinusoidal.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the section of the profiled steel plate 2 in the profiled steel plate concrete composite bridge deck is a continuous trapezoid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com