Prefabricated cover beam steel bar jig frame and manufacturing method of prefabricated cover beam reinforcement cage

A technology of reinforcing steel cages and covering beams, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of low installation accuracy of steel bars, unguaranteed thickness of protective layer, and difficult to control the positioning of steel bars and end grouting sleeves. Achieve the effect of improving production accuracy and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

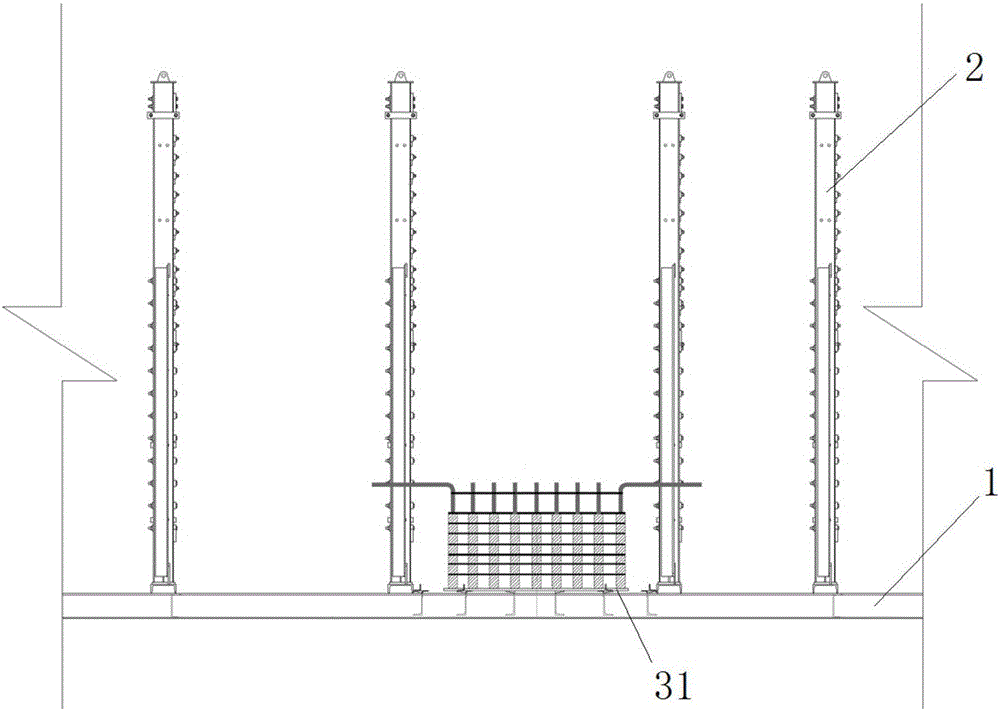

[0052] This embodiment provides a prefabricated cover beam steel tire frame, which is used in the prefabricated cover beam manufacturing process for accurately positioning the steel bars and end pre-embedded grouting sleeves in the prefabricated cover beam reinforcement cage. Such as figure 1 As shown, the prefabricated cap beam steel tire frame in this embodiment includes: an underframe 1 , a plurality of positioning frames 2 and a grouting sleeve positioning plate 31 . Among them, the underframe 1 is used to ensure the stability of the prefabricated cap beam reinforced tire frame system. The positioning frame 2 is provided with a main reinforcement positioning structure for accurately positioning the main reinforcement in the reinforcement cage of the prefabricated cover beam. The grouting sleeve positioning plate 3 is arranged on the underframe 1, and is used for positioning the end grouting sleeve of the prefabricated cover beam reinforcement cage.

[0053]The prefabrica...

Embodiment 2

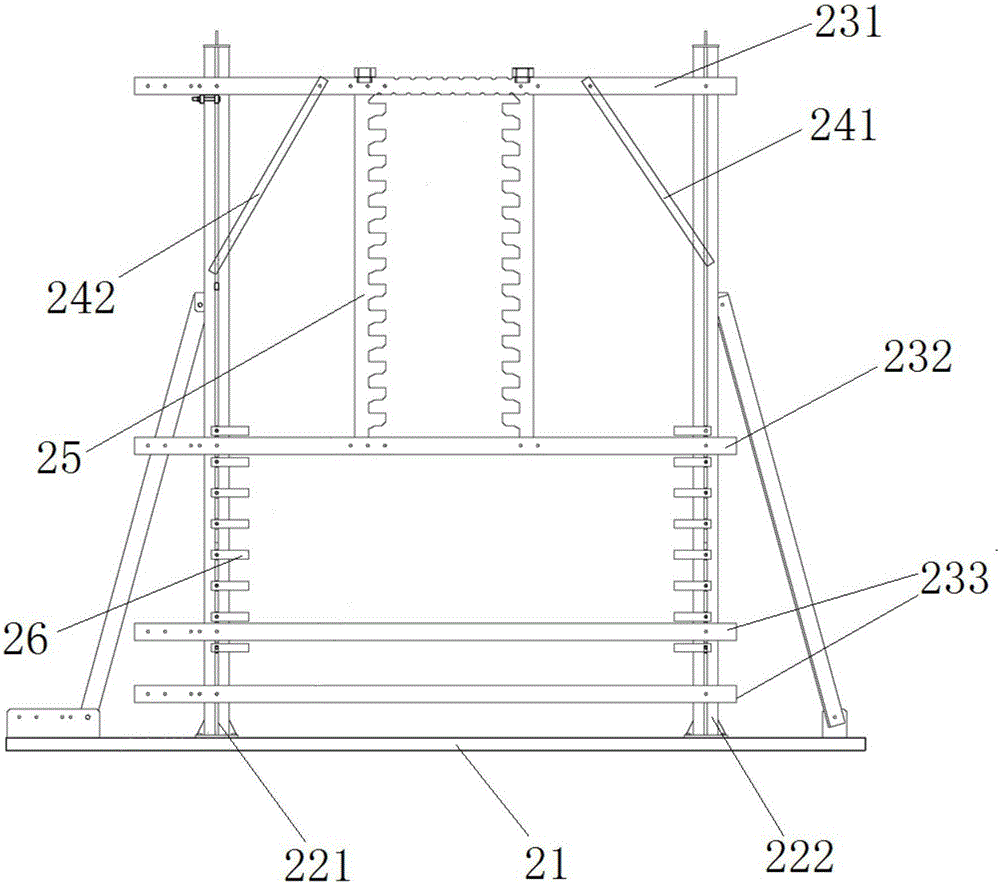

[0056] Preferably, this embodiment provides a prefabricated cap beam reinforced tire frame, compared with the previous embodiment, such as figure 2 As shown, the positioning frame of the prefabricated cap beam steel frame of this embodiment includes: supporting beams 21, columns and beams. Wherein, the supporting beam 21 is connected on the chassis. The columns are arranged on the supporting beams 21 . The uprights are preferably double uprights with diagonal braces, specifically, the uprights include first uprights 221 and second uprights 222 oppositely arranged. One end of the beam is connected to the first column 221 , and the other end is connected to the second column 222 . Wherein, the beam includes an upper beam 231 , a middle beam 232 and a lower beam 233 . The upper beam 231 is connected with the upper ends of the first column 221 and the second column 222 (that is, located at the upper part of the positioning frame); the lower beam 233 is connected with the lower...

Embodiment 3

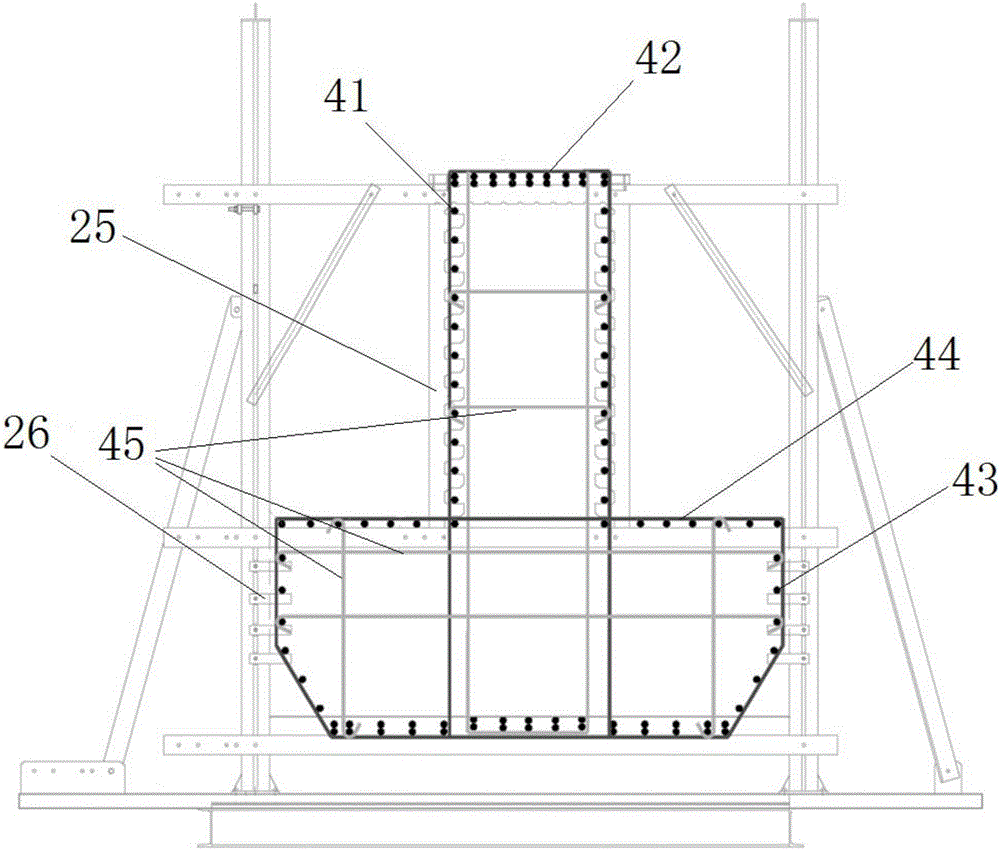

[0060] Preferably, this embodiment provides a prefabricated cap beam reinforced tire frame, compared with the above embodiments, such as figure 2 with image 3 As shown, the main reinforcement positioning structure includes a first main reinforcement positioning structure for positioning the upper main reinforcement 41 in the reinforcement cage of the prefabricated cover beam. Wherein, the first main reinforcement positioning structure includes a hanging plate 25, the hanging plate 25 is located between the first column 221 and the second column 222, and the upper end of the hanging plate 25 is fixed to the upper beam 231, and the lower end is fixed to the middle beam 232. A plurality of first positioning grooves are longitudinally arranged on the hanging plate 25 for positioning the upper main reinforcement vertically distributed in the reinforcement cage of the prefabricated cover beam. The number of hanging plates can be selected according to the shape of the prefabricate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com