Reticulated shell-annular truss frame-irregular-shaped combination column combined support spherical tank system capable of slightly moving

A technology of annular truss and combined columns, applied in the field of storage tanks for oil storage, can solve the problems of poor seismic performance of spherical storage tanks, and achieve the effects of reasonable stress, good wind resistance and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, the present invention will be further described:

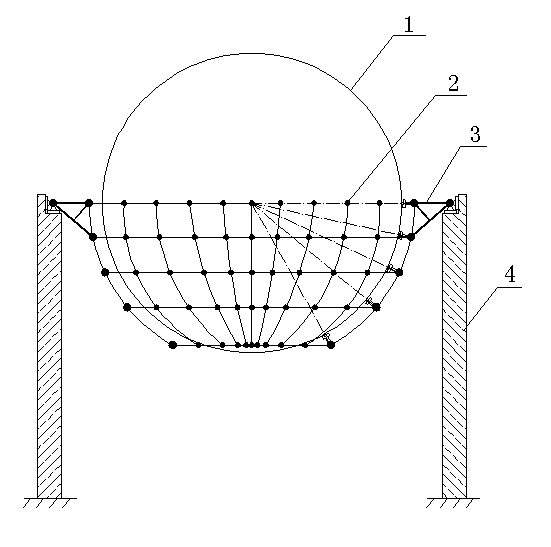

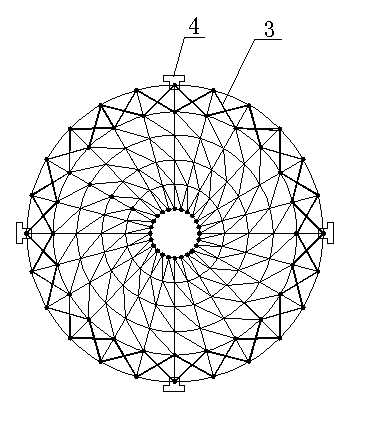

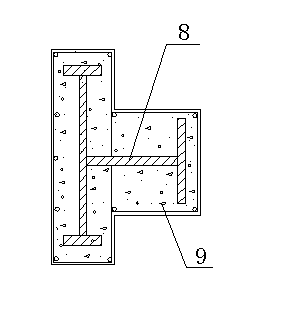

[0049] combine figure 1 , figure 2 As shown, this kind of reticulated shell-ring truss-special-shaped composite column joint support and micro-movable spherical tank system includes composite spherical tank 1, reticulated shell-ring truss-special-shaped composite column joint support, rubber ball-damper for shock absorption and energy dissipation Device; joint support of reticulated shell-ring truss-special-shaped composite column, ring truss 3 surrounds reticulated shell 2, ring truss 3 is connected with special-shaped composite column 4; composite spherical tank 1 is set on the joint of reticulated shell-ring truss-special-shaped composite column For support, a rubber ball-damper shock-absorbing and energy-dissipating device is arranged between the reticulated shell node 18 and the composite spherical tank 1. The annular truss 3 is arranged between the reticulated she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com