Rotary lifting construction method for cylindrical reticulated shell

A technology of cylindrical reticulated shell and construction method, applied in construction, building structure, construction material processing and other directions, can solve the problems of huge temporary support system engineering, unbearable workload, long construction period, etc., to achieve economic benefits and The social benefits are obvious, the structural force is reasonable, and the construction quality is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and with the best embodiment.

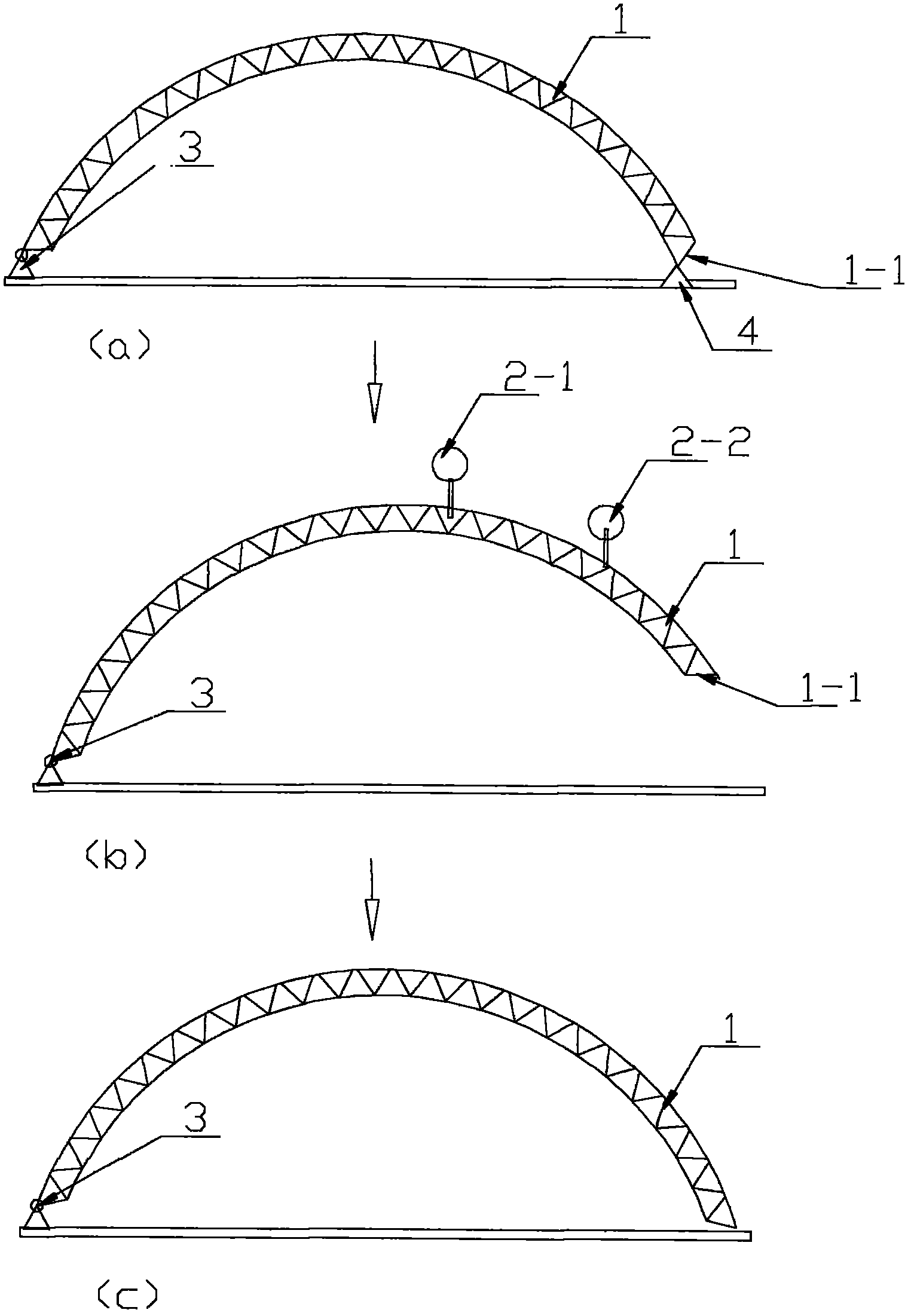

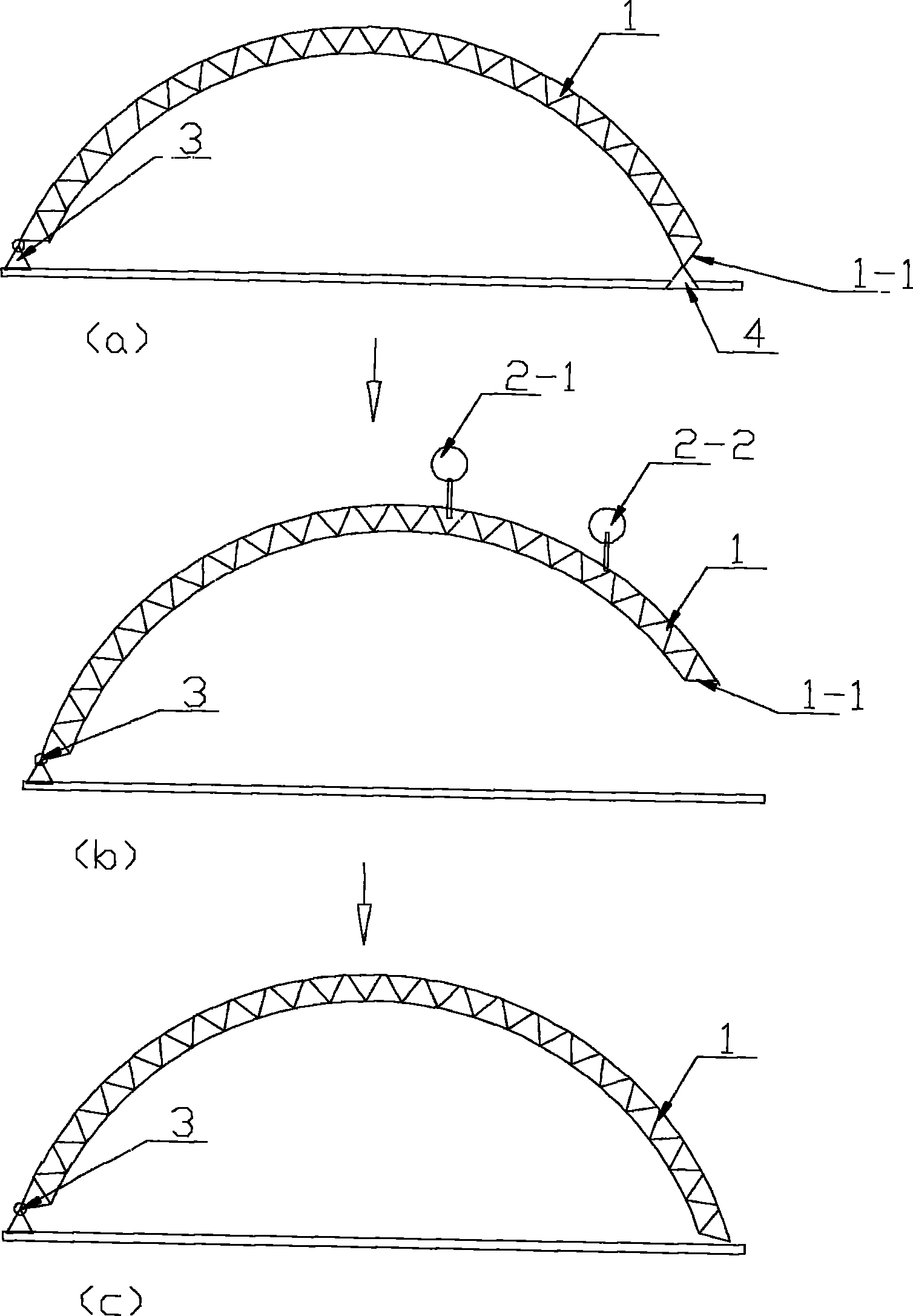

[0015] refer to figure 1 , cylindrical reticulated shell rotation lifting construction method, follow the steps below:

[0016] (1) Assembling the cylindrical reticulated shell 1 on the ground;

[0017] (2) One end of the assembled part of the cylindrical reticulated shell 1 is supported by the rotating hinge 3, and the other end is assembled to extend the operating surface 1-1 and supported by the temporary support 4;

[0018] (3) Use a hoist to lift the cylindrical reticulated shell 1, so that the cylindrical reticulated shell 1 rotates around the rotating hinge 3; and continue to assemble the cylindrical reticulated shell 1 on the assembly extension operation surface 1-1;

[0019] (4) The process of lifting and assembling is carried out alternately; the cylindrical reticulated shell 1 is extended along the arc direction until the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com