Efficient butt-joint laser welding method for laminated duplex-metal composite material

A layered bimetal and composite material technology, applied in the field of material processing, can solve problems such as complex procedures and low welding efficiency, and achieve the effects of reducing welding procedures, welding workload, and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments.

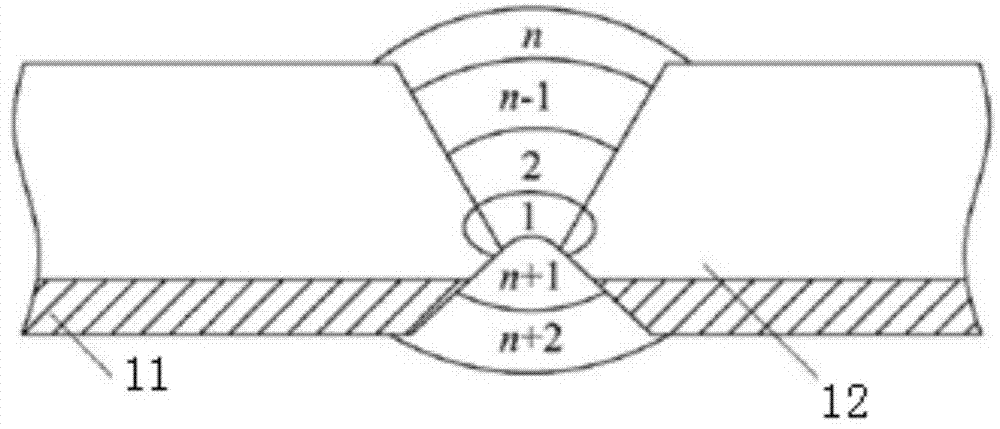

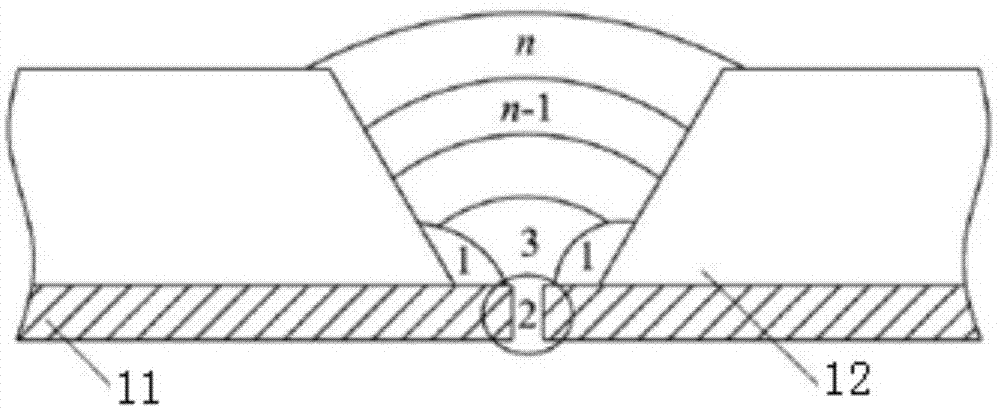

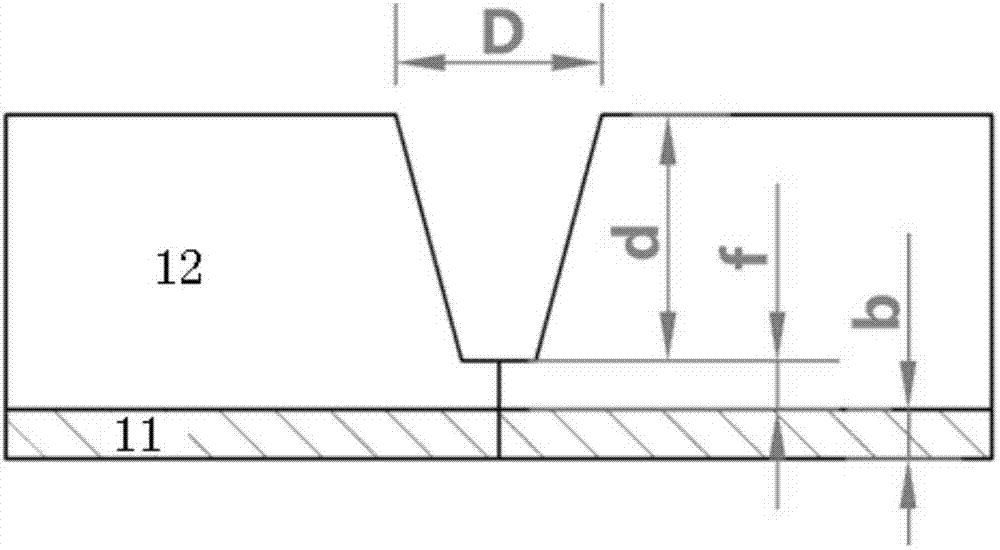

[0032] The invention provides a high-efficiency butt joint laser welding method for layered bimetallic composite materials, which is based on the characteristics of the liquid metal flow behavior in the molten pool and the layered structure of the layered bimetallic composite plate or composite pipe during laser penetration welding. A method proposed by the matching feature of the feature, with the help of the laser penetration welding process, the liquid metal in the upper and lower parts of the molten pool conducts Marangoni convection at their respective positions under the action of metal vapor friction and temperature gradient, and There is little convective exchange between each other, and the one-time welding forming technology of layered bimetallic composite materials is realized on the basis of ensuring the respective performance characteristics of the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com