Double-wall cofferdam with partitioned cabins

A technology of cofferdams and wall partitions, applied in the field of enclosure structures for underwater construction, can solve the problems of large processing and welding workload of rods, high production cost of cofferdams, large volume and weight, etc., and achieve small welding workload , Simplified assembly and manufacturing process, less material specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

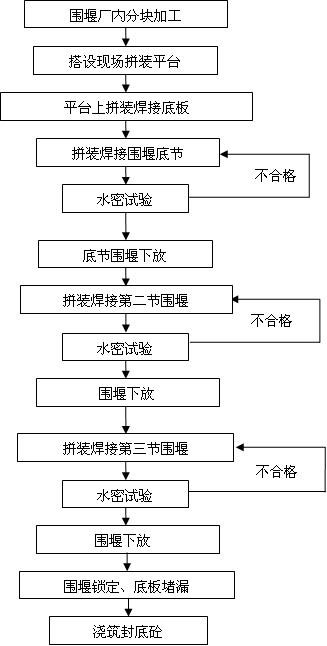

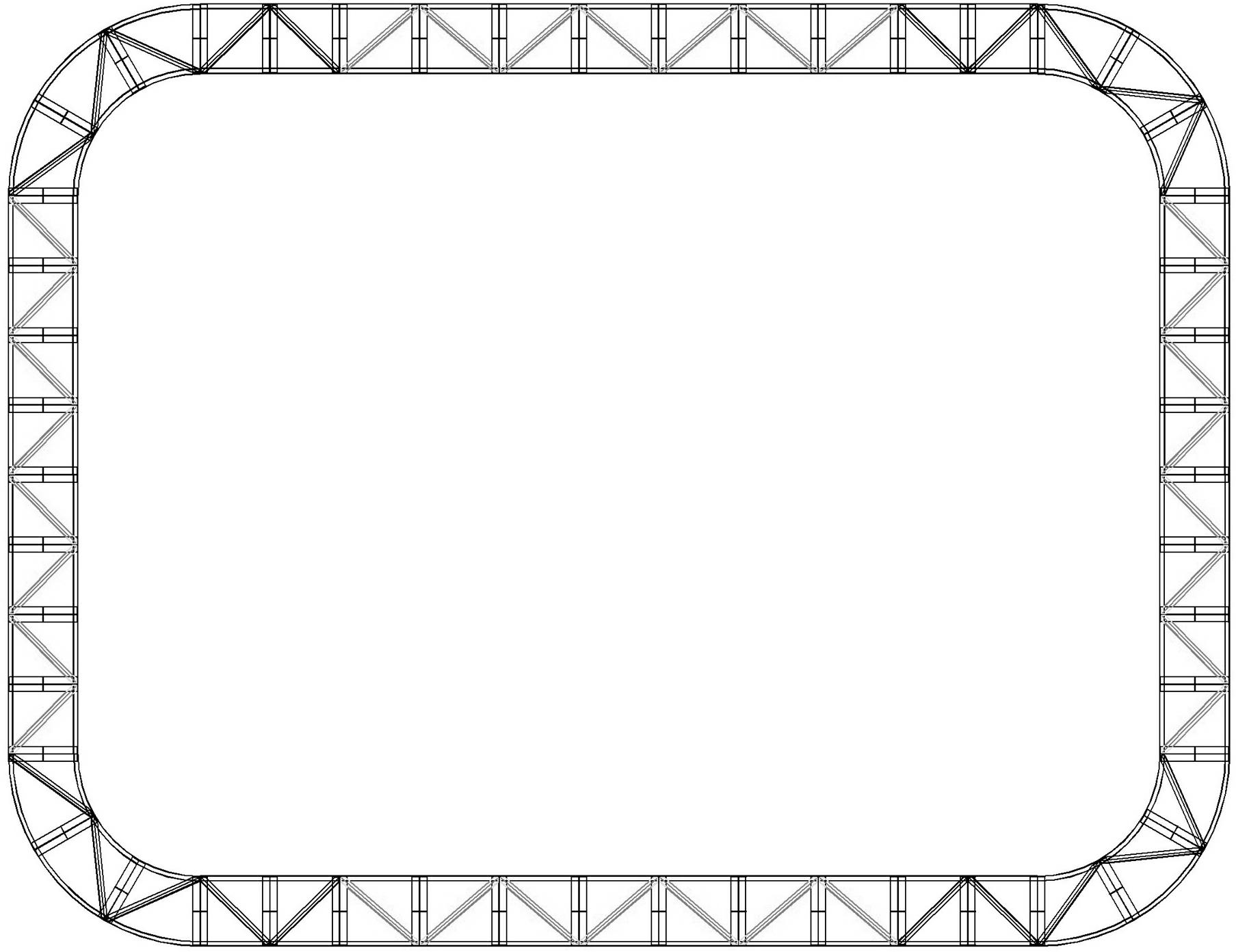

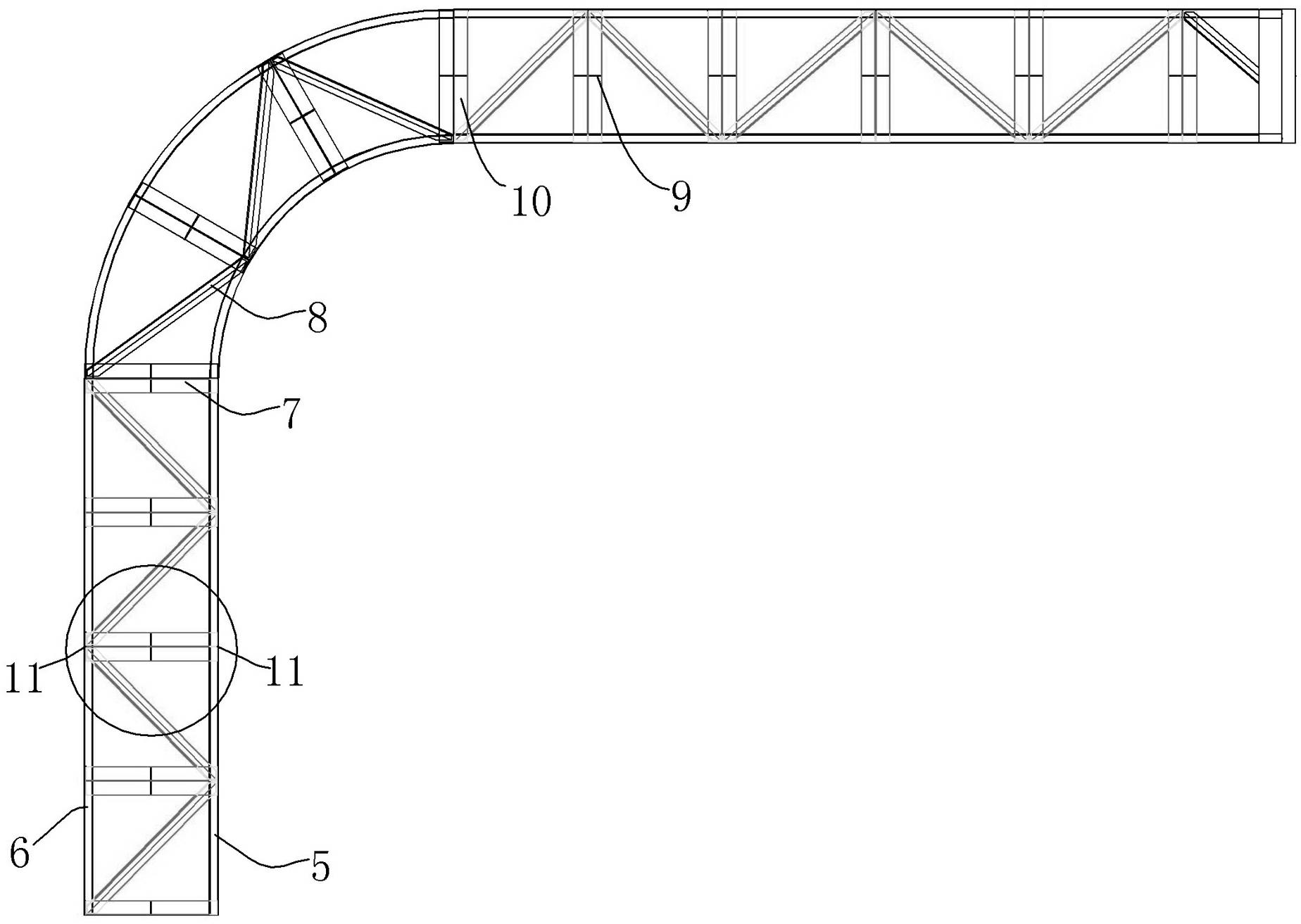

[0015] Such as figure 1 , figure 2 , image 3 As shown, a double-wall compartment type cofferdam is provided. The inner wall plate 5, the outer wall plate 6 and the bottom plate 1 are connected to form a rounded rectangular structure with bottom sealing. It forms a circular cavity with rounded corners, and the compartment plate 7 perpendicular to the inner wall plate 5 and the outer wall plate 6 vertically divides the cavity into a plurality of independent compartments that are not connected to each other. The position is provided with parallel oblique rods 8 parallel to the bottom plate 1, and the parallel oblique rods 8 in adjacent cabins are arranged symmetrically with the bulkheads. Connect one at an interval of 1.0-1.5mm, and each parallel oblique rod 8 forms a triangular stable structure with the compartment plate 7 and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com