Mixed shear connector

A shear-resistant connector and connector technology, which can be applied to buildings, building structures, etc., can solve problems such as difficulty in fitting calculation formulas, inconvenient application, etc., achieving good social benefits and transformation prospects, convenient connection, and reducing total cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

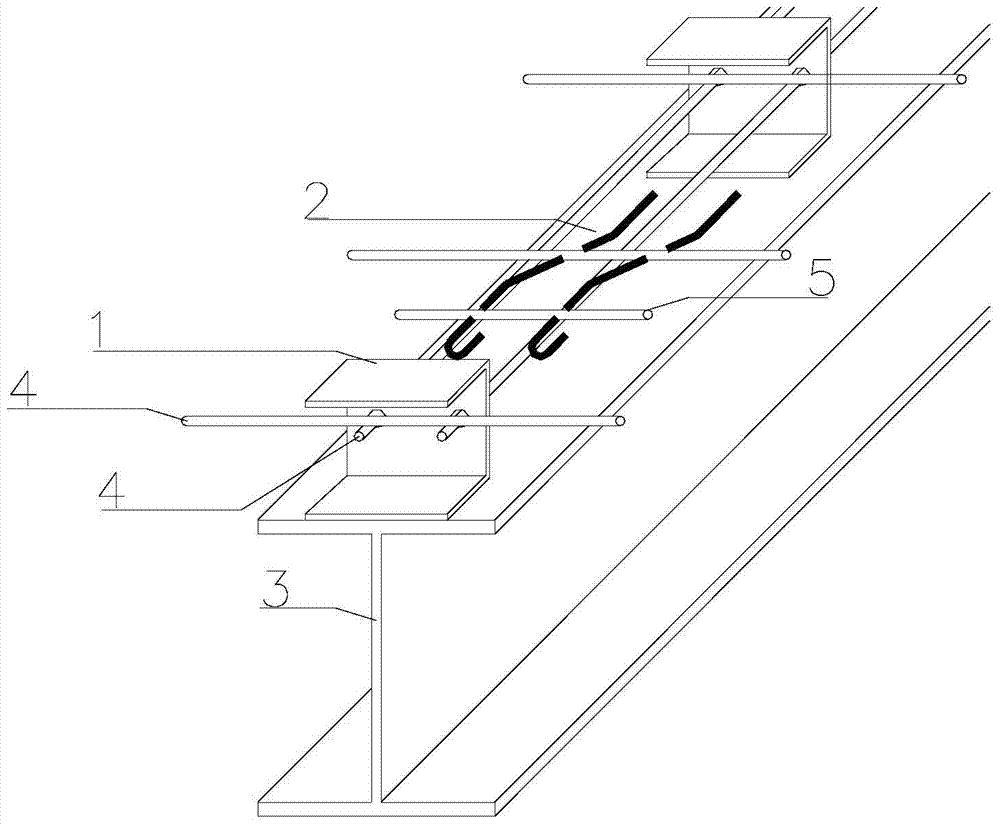

[0020] Such as figure 1 As shown, a hybrid shear connector includes a channel steel connector 1 and a bent steel bar connector 2, the channel steel connector 1 and the bent steel bar connector 2 are arranged in the floor, the channel steel connector 1 and the bent steel bar connector 2 The bent steel bar connectors 2 are alternately arranged on the steel girder 3, the channel steel connectors 1 should be arranged at the beam end, the web of the channel steel connector 1 is provided with a reserved hole, and the longitudinal direction of the steel mesh in the floor slab Steel bars 4 pass through the reserved holes.

[0021] An additional transverse reinforcement 5 is added to the bent-up reinforcing bar connector, and is fastened with the bent-up reinforcing bar connector 2 .

[0022] The above is only a preferred embodiment of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com