Buckling restrained brace with steel pipe concrete sleeved on round pipe as inner core

A steel tube concrete, buckling restraint technology, applied to bridge parts, building components, bridges, etc., can solve the problems of difficult inspection, inconvenient construction, high cost, etc., and achieve the effect of light weight, fast processing, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

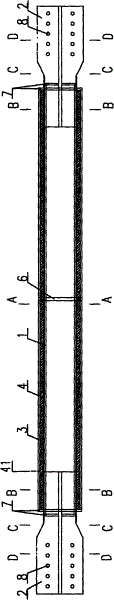

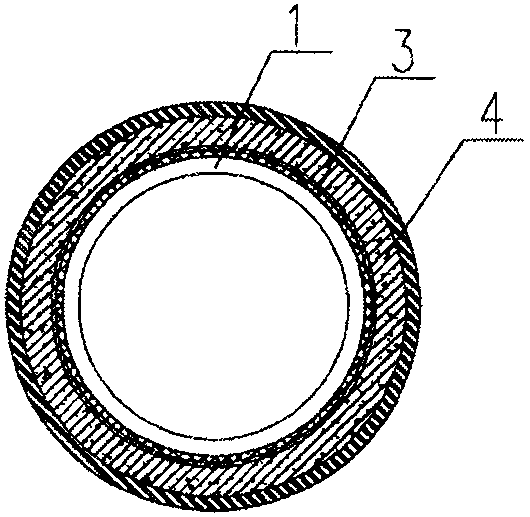

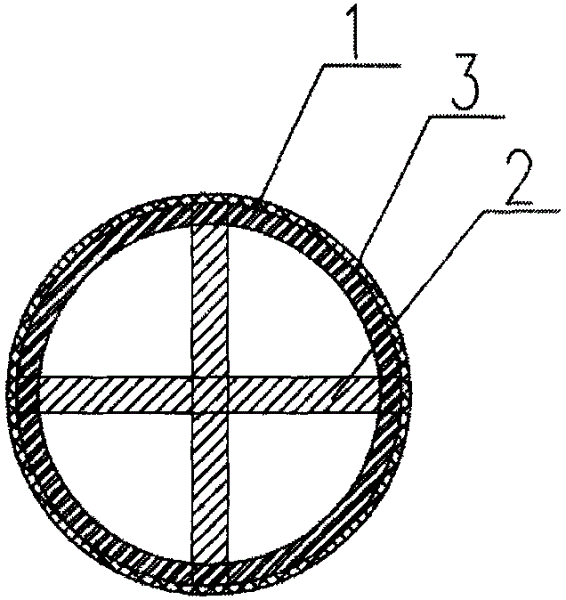

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a kind of inner core of the present invention is a buckling-constrained support of circular tube jacket concrete-filled steel tube, which is composed of inner-core steel support member, unbonded material layer 3 and outer-wrapped steel-tube concrete member 4, wherein the inner-kernel steel support member is composed of It is composed of a cylindrical steel pipe 1, the non-bonding material layer 3 is covered on the outer peripheral wall of the cylindrical steel pipe 1, the outsourcing steel pipe concrete member 4 is a tubular member, and the cylindrical steel pipe 1 is arranged on the outsourcing Inside the CFST member 4, there is a gap between the non-adhesive material layer 3 and the inner wall of the outsourcing CFST member 4, and a cross-shaped connecting steel plate 2 is fixedly welded to each of the two ends of the cylindrical steel pipe 1. The cross-shaped connecting steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com