Vehicle body of railroad vehicle and railroad vehicle

A technology for railway vehicles and car bodies, which is applied to railway car bodies, railway car body parts, transportation and packaging, etc., can solve the problems of increasing the welding workload of car body connections, welding deformation, and reducing work efficiency, and achieves a reduction in welding work. quantity, improve welding efficiency, and ensure the effect of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

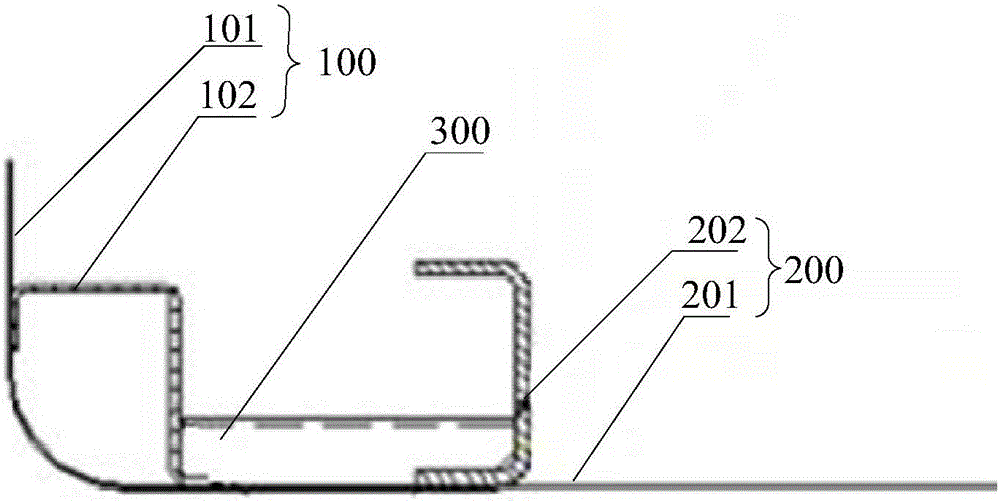

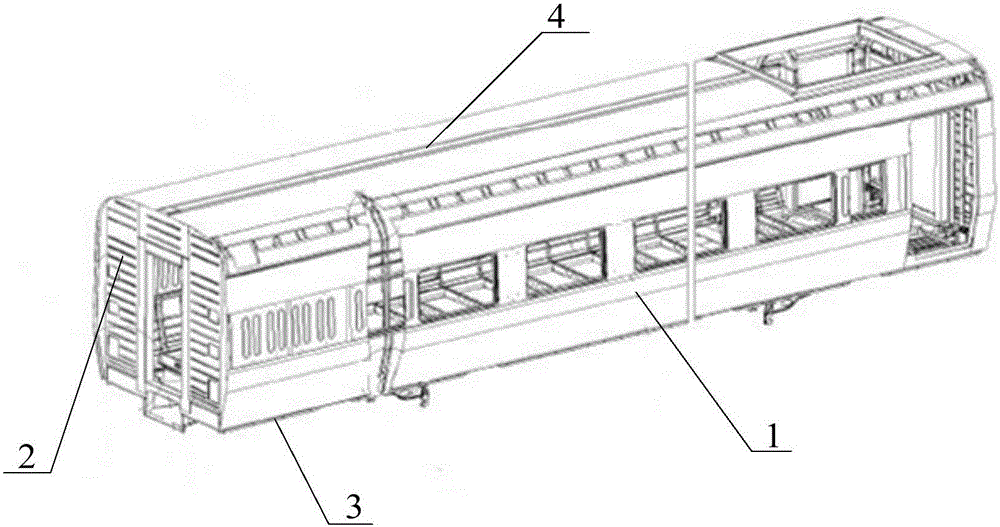

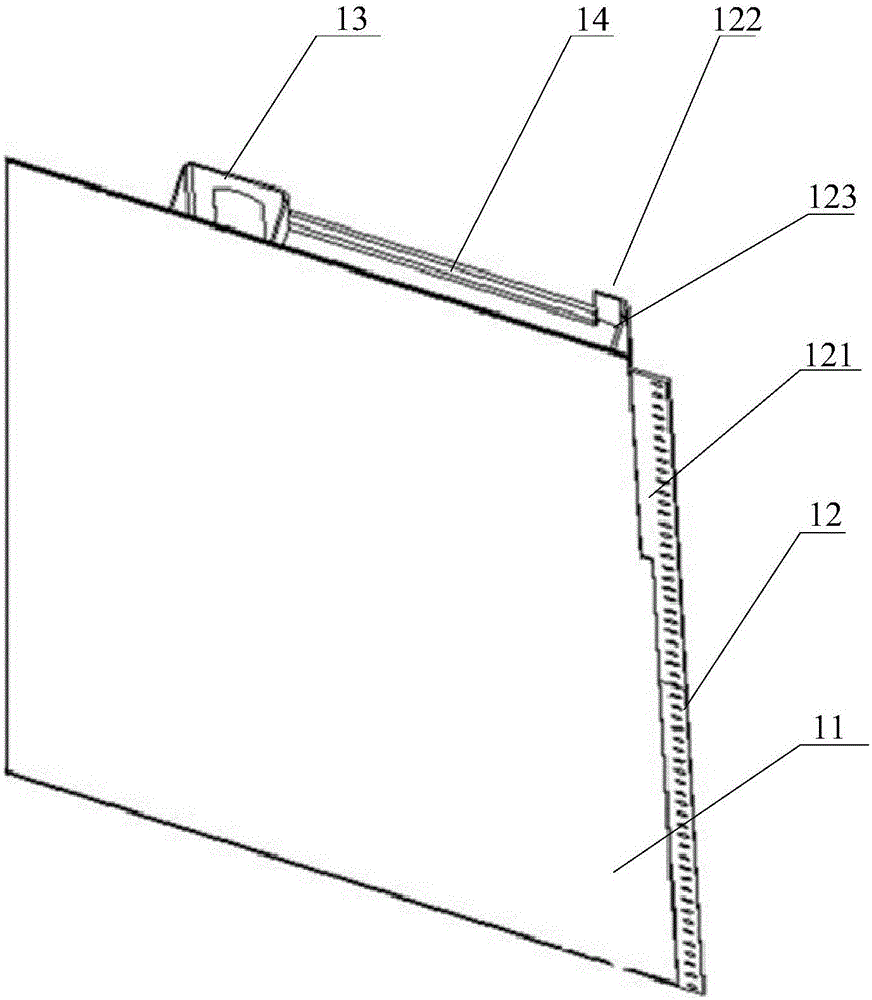

[0055] figure 2 A schematic diagram of the overall structure of the railway vehicle body provided by Embodiment 1 of the present invention; image 3 A schematic structural diagram of a side wall of a railway vehicle body provided in Embodiment 1 of the present invention; Figure 4 Schematic diagram of the structure of the end wall of the railway vehicle body provided by Embodiment 1 of the present invention; Figure 5 A schematic diagram of the connection between the side wall and the end wall of the railway vehicle body provided by Embodiment 1 of the present invention; Image 6 A top view of the connection between the side wall and the end wall of the railway vehicle body provided by Embodiment 1 of the present invention.

[0056] Please also refer to the following Figure 2 to Figure 6, the railway vehicle body provided in this embodiment includes: side wall 1, end wall 2, underframe 3, roof 4, wherein: side wall 1 and end wall 2 are welded on the underframe 3 respectiv...

Embodiment 2

[0086] This embodiment provides a railway vehicle. The railway vehicle provided in this embodiment includes a bogie and the railway vehicle body provided in Embodiment 1 of the present invention, wherein the railway vehicle body is arranged on the bogie.

[0087] Specifically, the structure and function of the railway vehicle body are similar to those of the foregoing embodiments, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com