Construction welding method for main chord pipe inside platform legs

A welding method and the technology of the main side pipe, which are applied in welding equipment, construction, manufacturing tools, etc., can solve the problems of high strength and impact toughness, easy weld defects, and low welding work efficiency, so as to improve mechanical properties, The effect of reducing weld defects and reducing welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

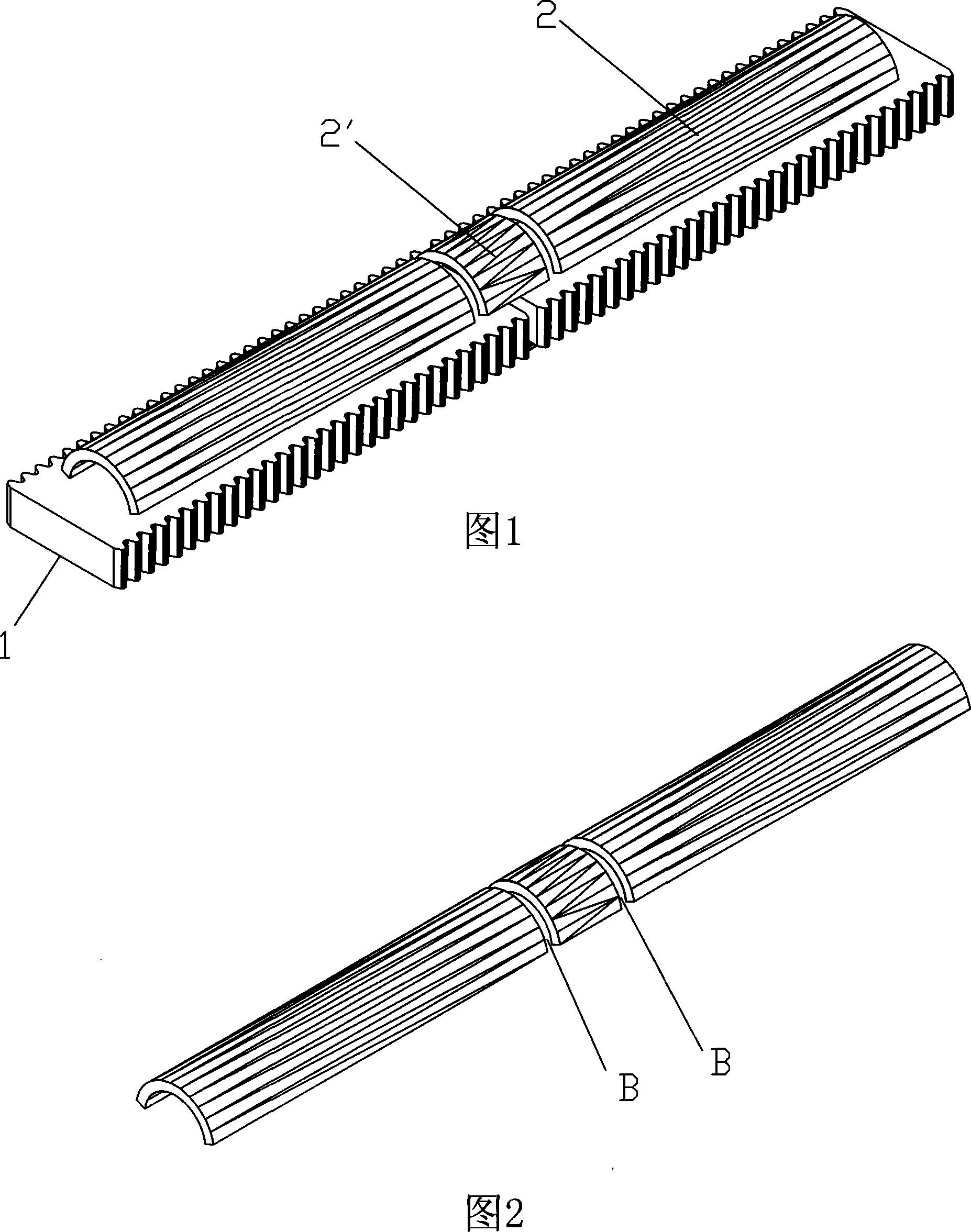

[0019] The pile leg structure related to the present invention is mainly used in a jack-up drilling platform with a water depth of 400 feet. The structure of its main side tube is shown in Figure 9, including a semicircular plate 2 and a rack plate 1. Referring to FIG. 1 , the main side tube is connected by a plurality of connecting sections, wherein each connecting section includes a rack plate 1 arranged in the middle and semicircular plates 2 symmetrically arranged on both sides of the rack plate 1 .

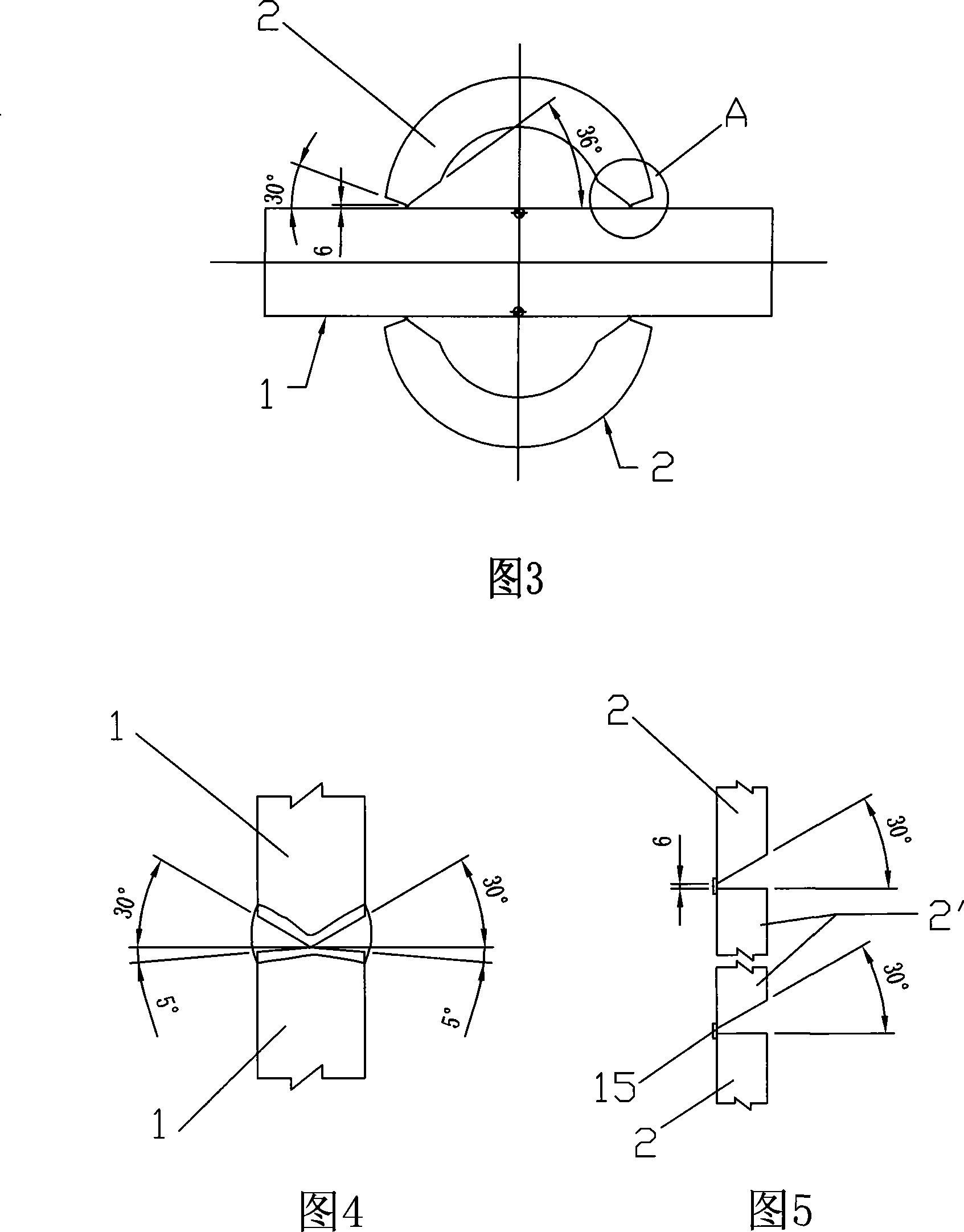

[0020] With reference to Fig. 2-8, illustrate welding method of the present invention, comprises the steps:

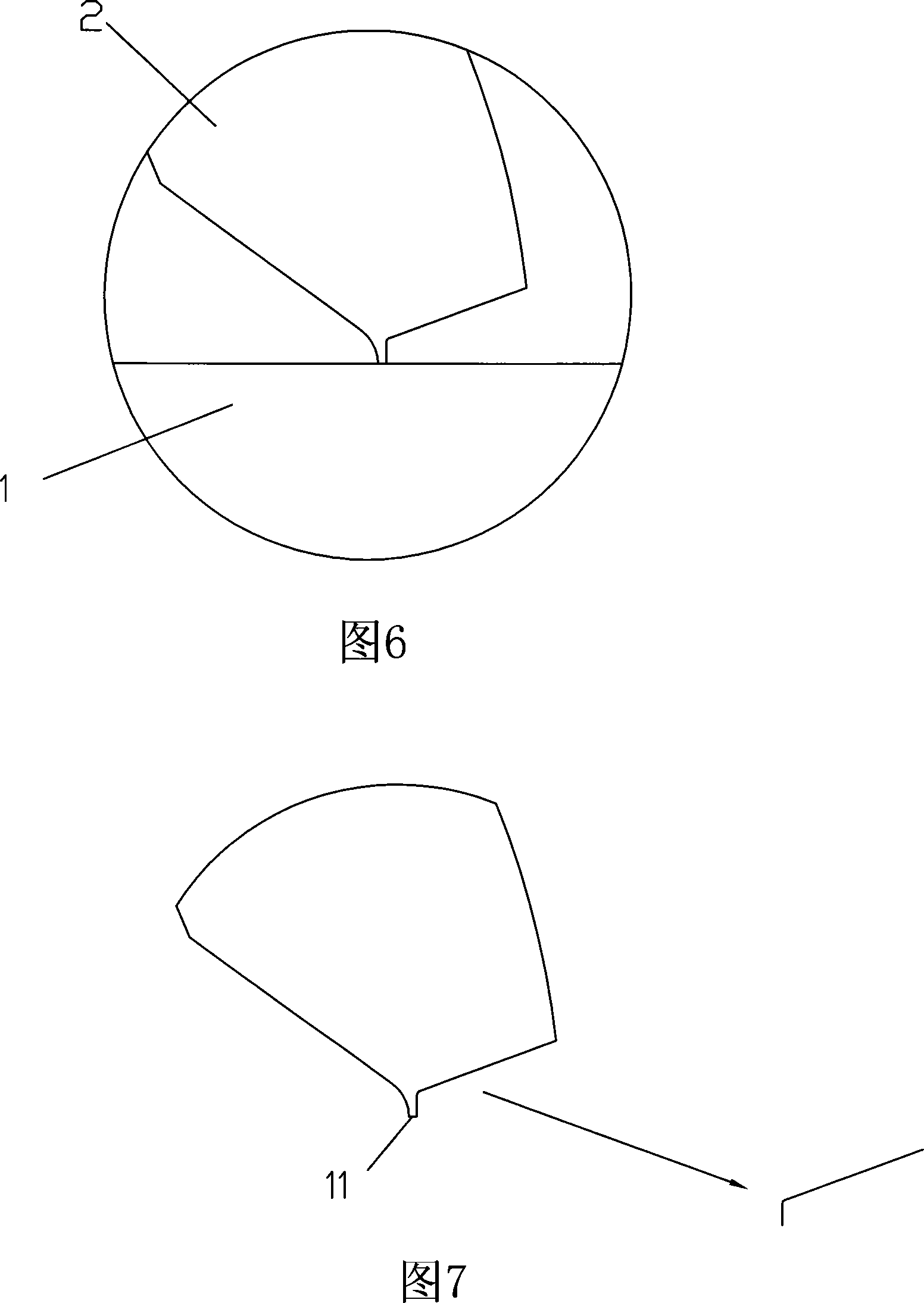

[0021] a. The semicircular plate 2 on both sides and the rack plate 1 are welded together in the joint form of a single-sided U-shaped groove, and the semicircular plate 2 is located in the middle of the rack plate 1 and is shorter than the rack plate 1; At the welding place between the plate 2 and the rack plate 1 , the root of the semicircular plate 2 is provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com