Long continuous structural steel box beam or combination box beam construction method

A construction method and technology of structural steel, applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of difficult control of construction period, difficult safety and quality control, large welding workload, etc., and achieve the effect of reducing welding workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

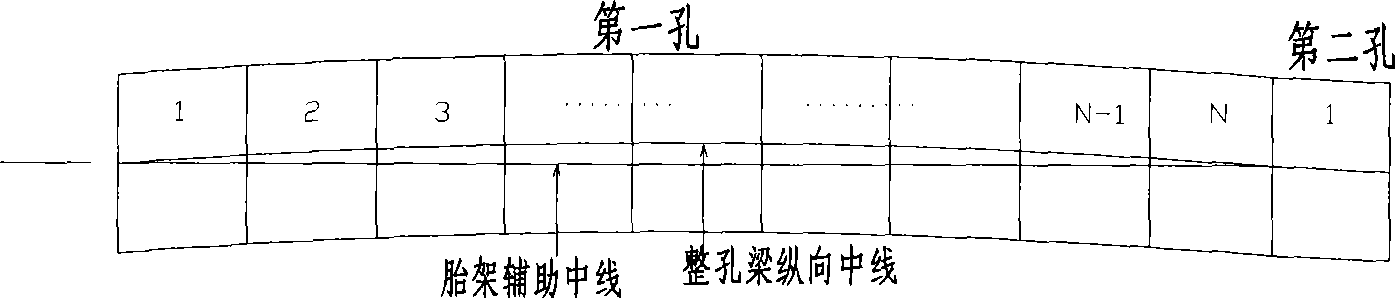

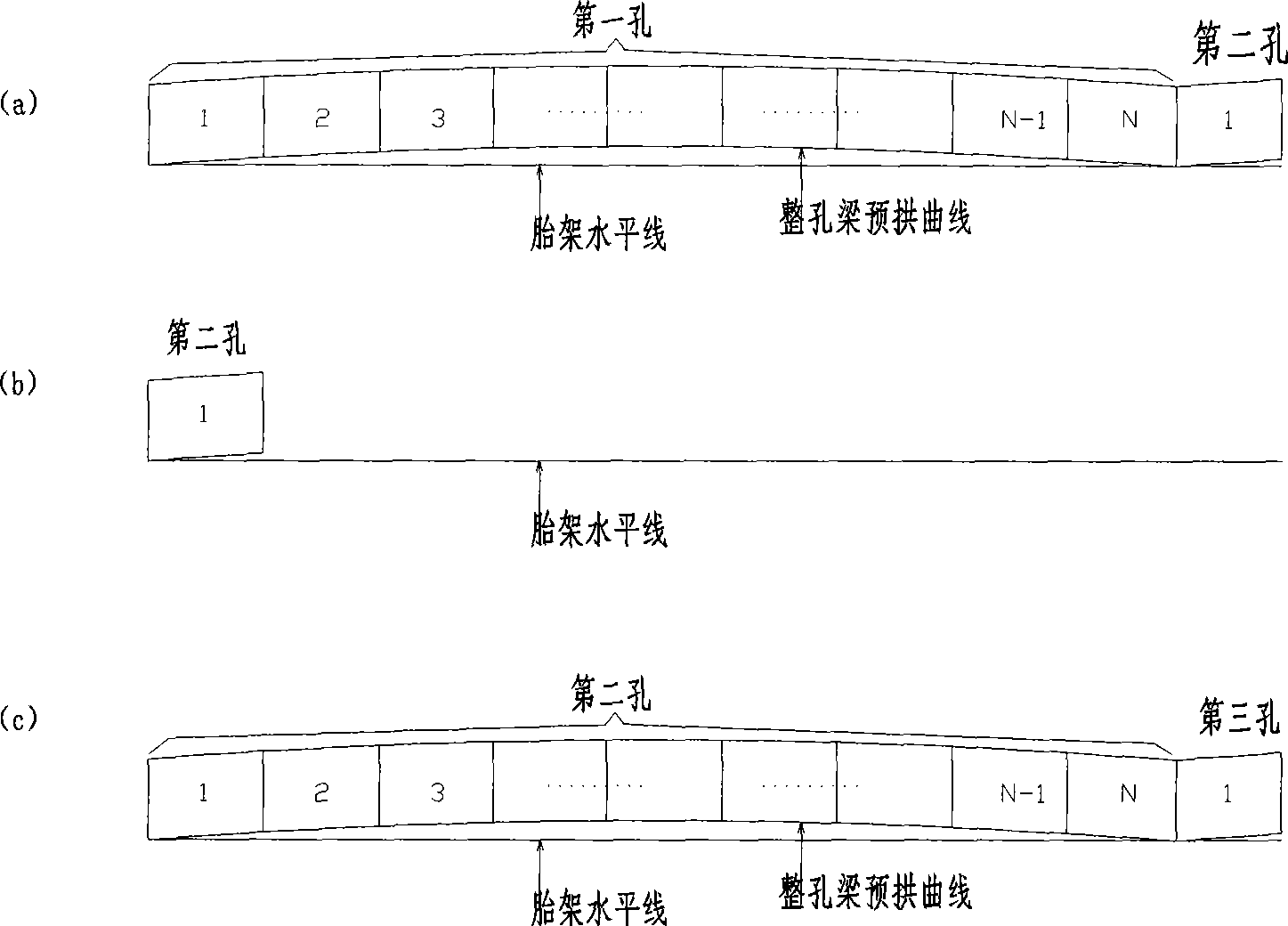

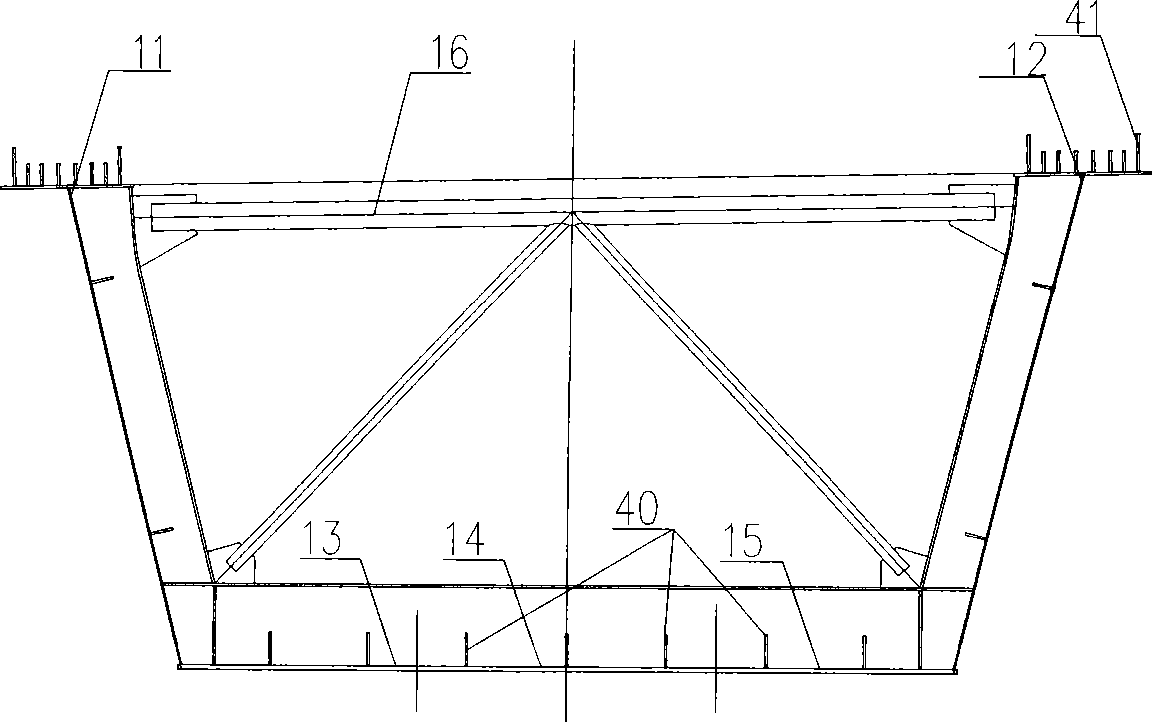

[0022] Hereinafter, the construction method of the channel steel beam of the 105m steel-concrete composite box beam of the Shanghai Yangtze River Tunnel Bridge is taken as an example to illustrate the present invention in detail:

[0023] The combined span of the steel-concrete composite box girder of the Shanghai Yangtze River Tunnel Bridge is (85+5×105+90)m, and the continuous box girder structure of the steel-concrete composite structure is adopted. The emergency parking zone is arranged according to the two-way four-lane + emergency parking zone + rail transit arrangement in the long term, and the bridge width is 2×17.15m. The plane line shape of a combined box girder is the curve section of the design road centerline. The south side of the bridge transitions from a curve with a radius of curvature R=8000m to a straight line, and the north side connects from a straight line to a curve with a radius of curvature of R=7000m. When putting together, the 85, 90 and 105m box girders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com