Connection joint of concrete filled steel tubular column and enclosed U-shaped steel concrete composite beam

A technology for steel pipe concrete columns and connection nodes, which is applied in the direction of construction and building construction, can solve the problems of reducing on-site welding workload, affecting the appearance, and weakening the bearing capacity, so as to reduce the on-site welding workload, save materials, and reduce weakening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0050] Composite beam: refers to the abbreviation of U-shaped steel concrete composite beam.

[0051] High-strength bolts: refer to high-strength bolts, which are a standard part. In general, high-strength bolts can withstand a larger load than ordinary bolts of the same specification.

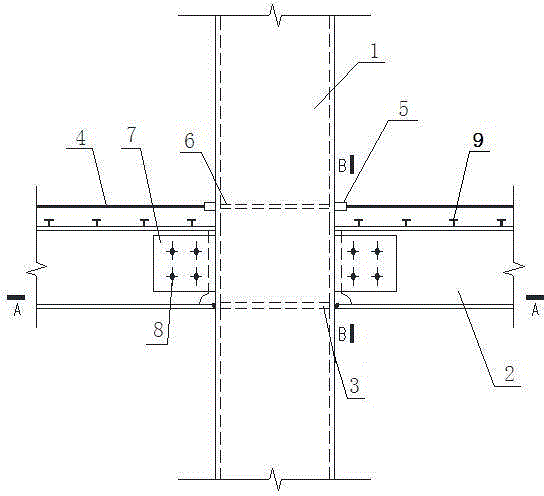

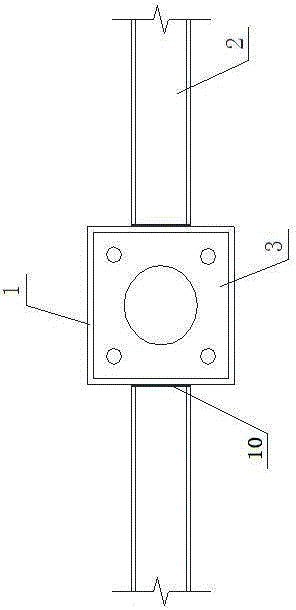

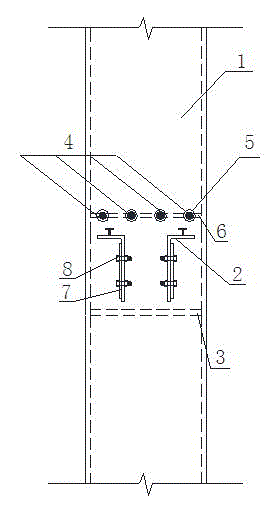

[0052] A connection node between a steel pipe concrete column and an outer U-shaped steel concrete composite beam, as shown in the figure, it includes an inner partition 3 and a horizontal stiffening plate 6, and the inner partition 3 and the horizontal stiffening plate 6 are respectively provided with pouring holes 12 and air vent 11, guarantee the smooth progress of concrete pouring in the steel pipe 1. The inner partition 3 is located in the steel pipe 1 corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com