Fiber reinforced thermoplastic composite panel

a thermoplastic composite panel and fiber technology, applied in the direction of glass/slag layered products, layered products, constructions, etc., can solve the problems of no mass production, no field application or demonstration, fabrication of arched profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

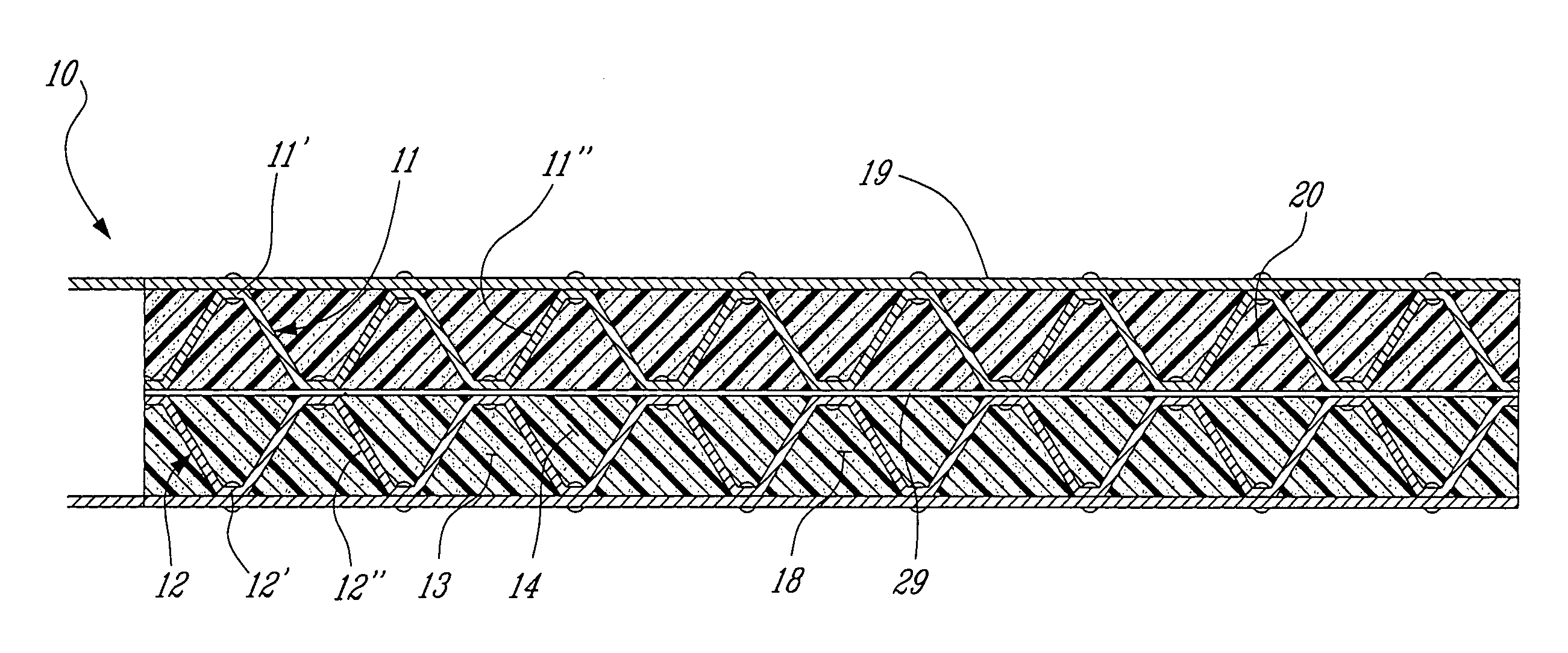

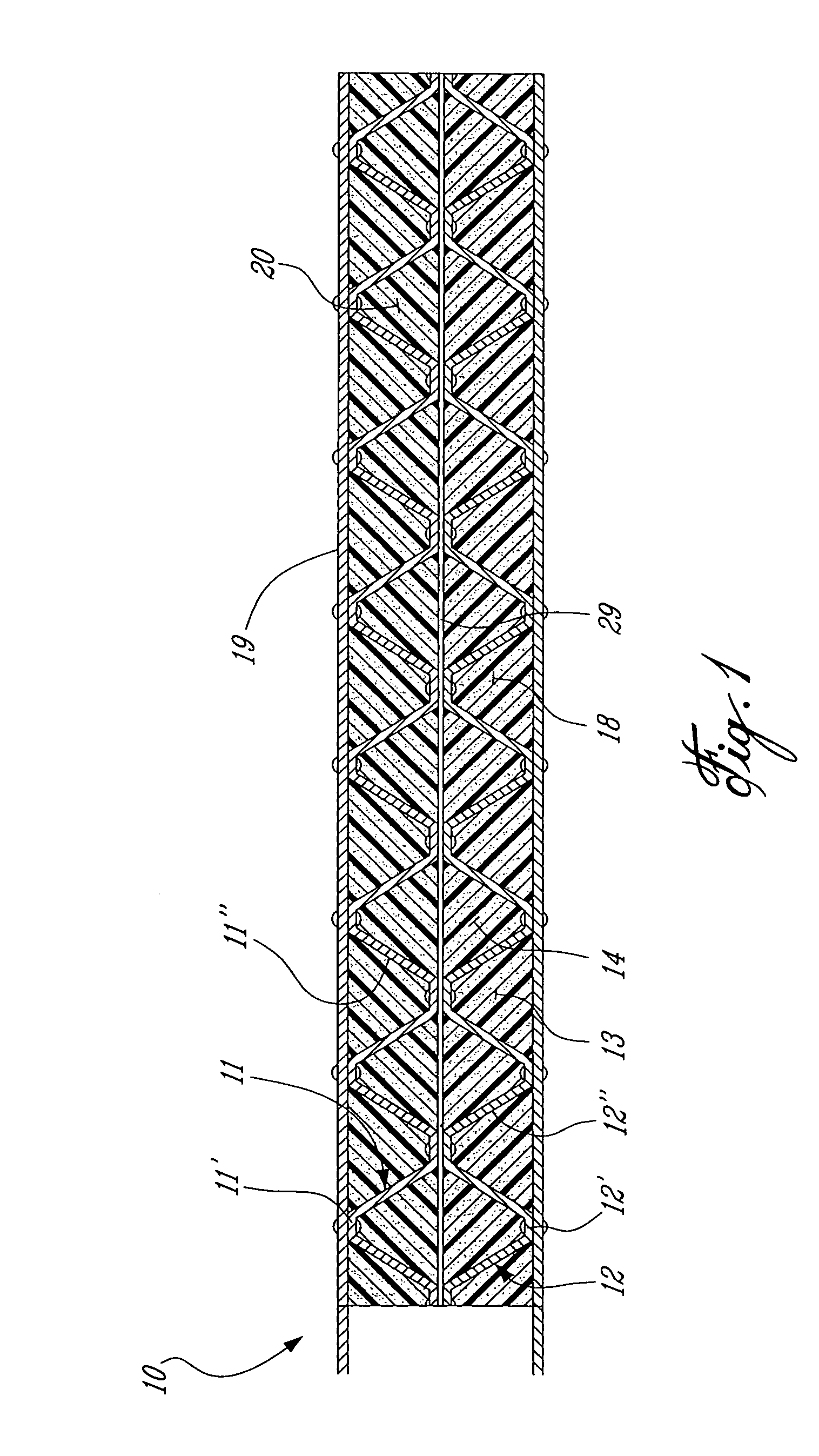

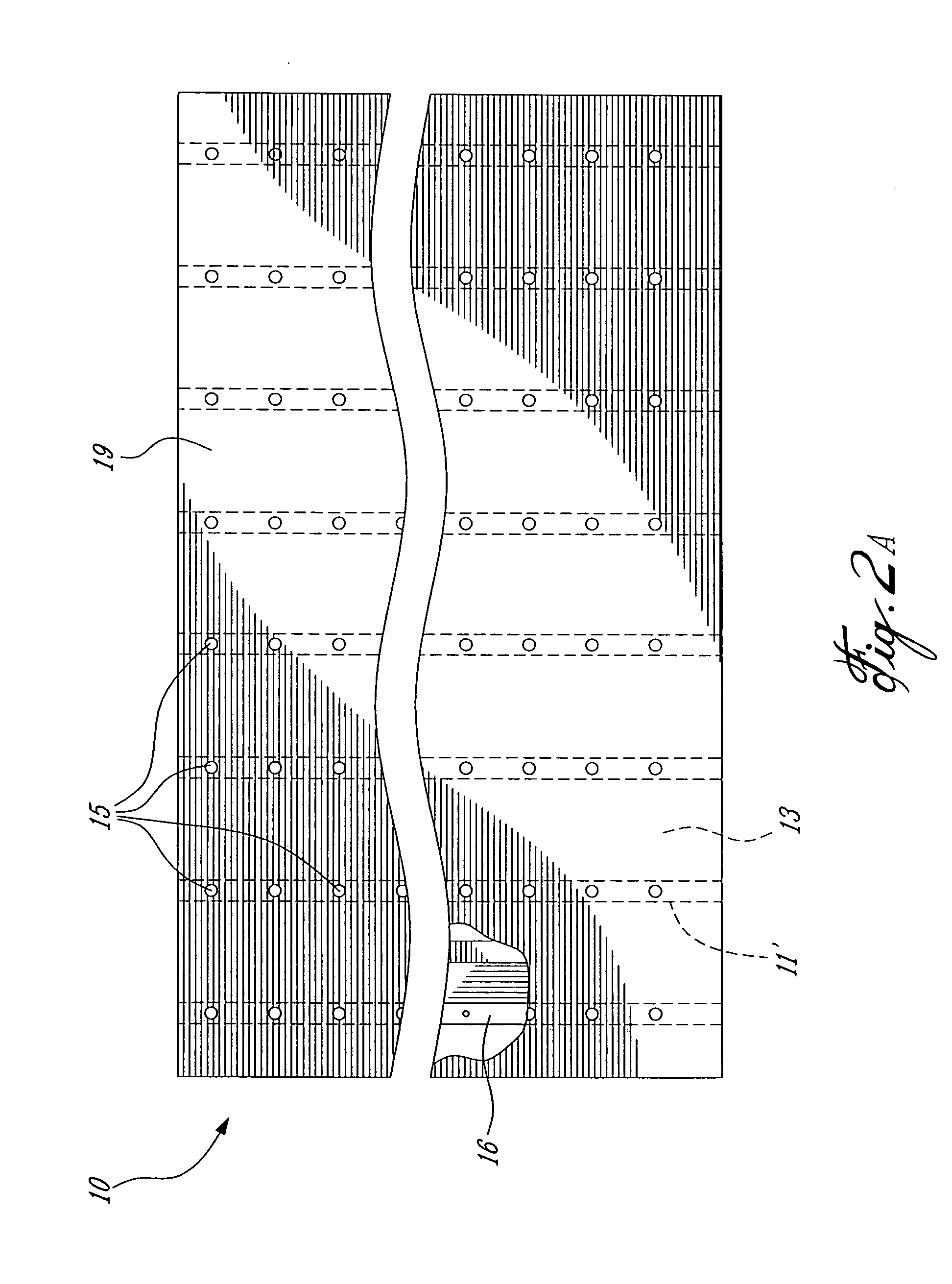

[0024]Referring now to the drawings and more particularly to FIGS. 1 and 2, there is shown generally at 10 a fiber reinforced thermoplastic composite panel constructed in accordance with one embodiment of the present invention. The panel comprises two corrugated sheets 11 and 12 formed of commingled glass fiber reinforced polypropylene (FRP) by a continuous roll forming process. Each of the corrugated sheets 11 and 12 define a plurality of opposed and offset spaced-apart connecting ridge sections 11′, 11″ and 12′ and 12″ and integrally formed intermediate trough sections 13 and 14 formed between the connecting ridge sections. The two corrugated sheets 11 and 12 are interconnected in superimposition, as hereinshown, by connection means which is hereinshown by high tensile bolts 15 interconnecting abutting ridge sections together. A web of FRP material having a thickness of about 1.6 mm is shown at 29 and interconnected by the bolts 15 between the connecting ridges between opposed dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com