Design method for longitudinal pre-stressing tendons of variable-cross-section pre-stressed concrete continuous bridge

A technology of prestressed beams and design methods, applied in bridge construction, bridges, calculations, etc., can solve the problems of difficulty in assuming parameters, complicated and lengthy, and low efficiency in the calculation formula of prestressed reinforcement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

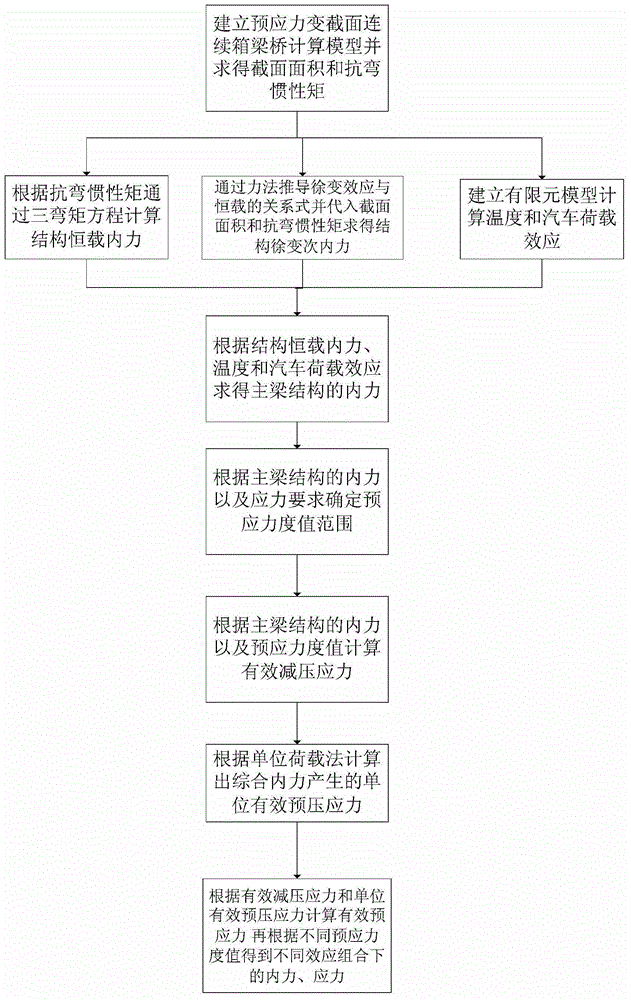

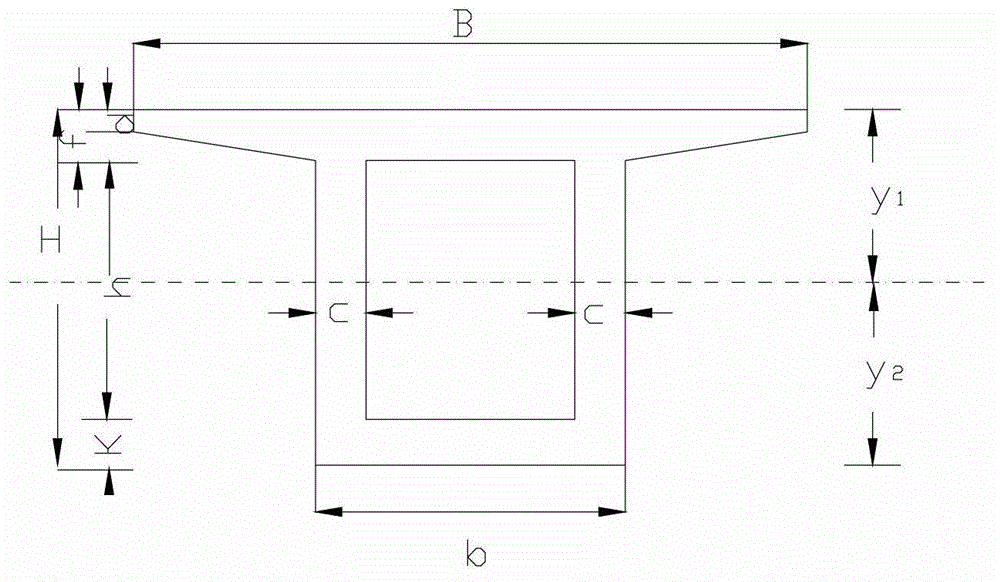

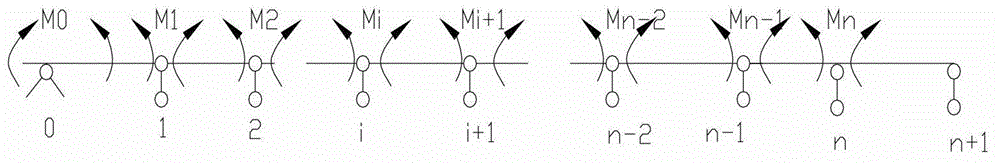

[0092] see figure 1 , in the embodiment, by establishing the main span range of 50m, 100m and 150m continuous box girder bridge calculation model of prestressed variable section, determine the bridge type, section form, determine the line shape of the prestressed beam according to the principle of prestressed beam layout and The position is to use a box section of conventional size (for example, the beam height is L / 17, the bottom plate changes according to a quadratic parabola, and the web adopts a gradual change) and the side-to-middle span ratio. Furthermore, the internal force calculation of the main beam is carried out, and the effective precompression stress of the prestressed beam under the unit load is calculated. Since the shrinkage and creep effect of statically indeterminate concrete structure is related to the prestressing effect, a prestressing degree is assumed first, and the longitudinal prestressing beam design of the prestressed concrete continuous girder brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com