A method for installing a ship stern shaft

An installation method and a technology of the stern shaft, which are applied in ship construction, ship design, ship parts, etc., can solve the problems of occupying resources of heavy flatbed trucks, increasing the workload of welding and removing lifting codes, and low operability accuracy of heavy flatbed trucks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

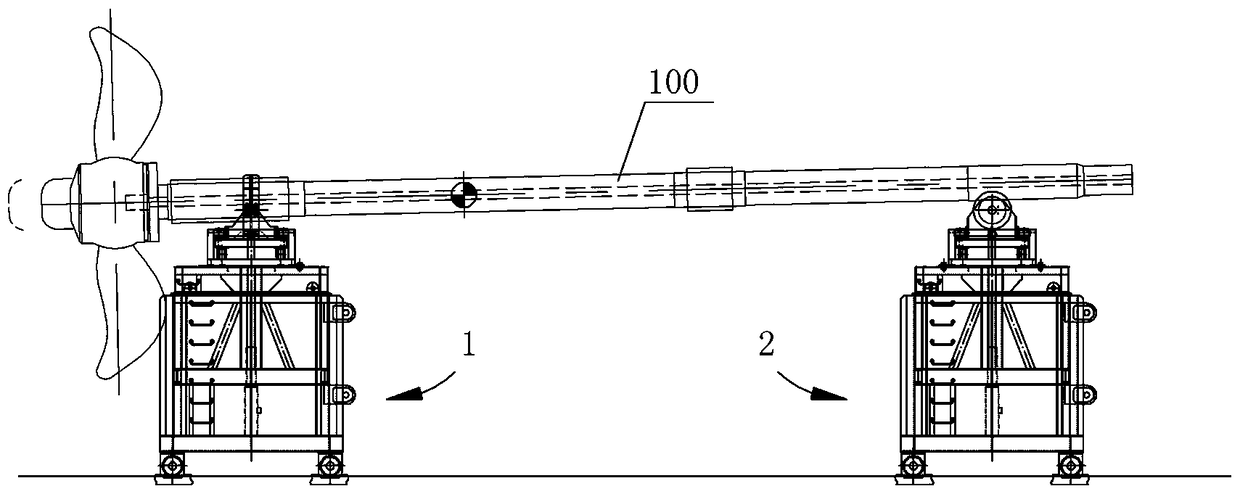

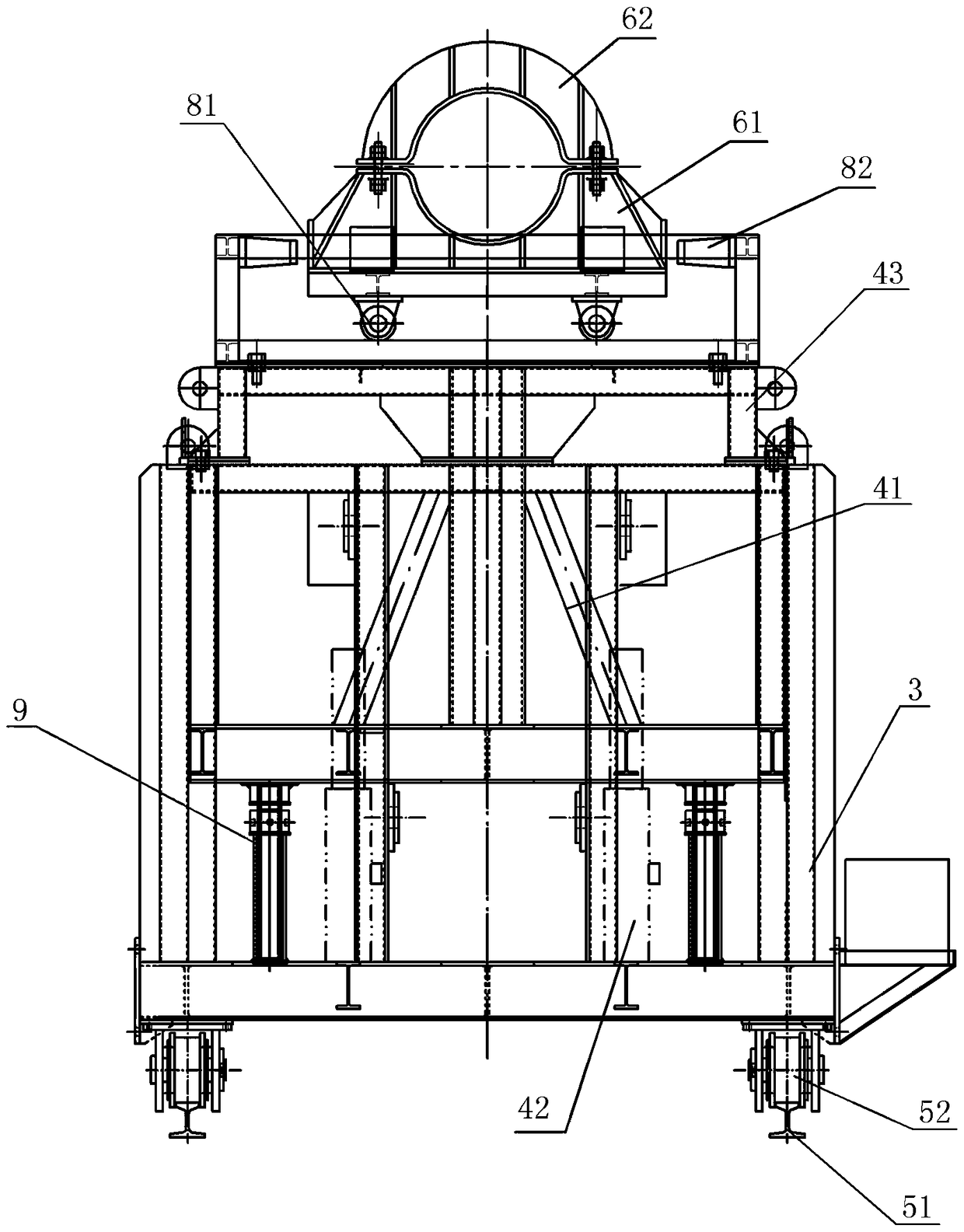

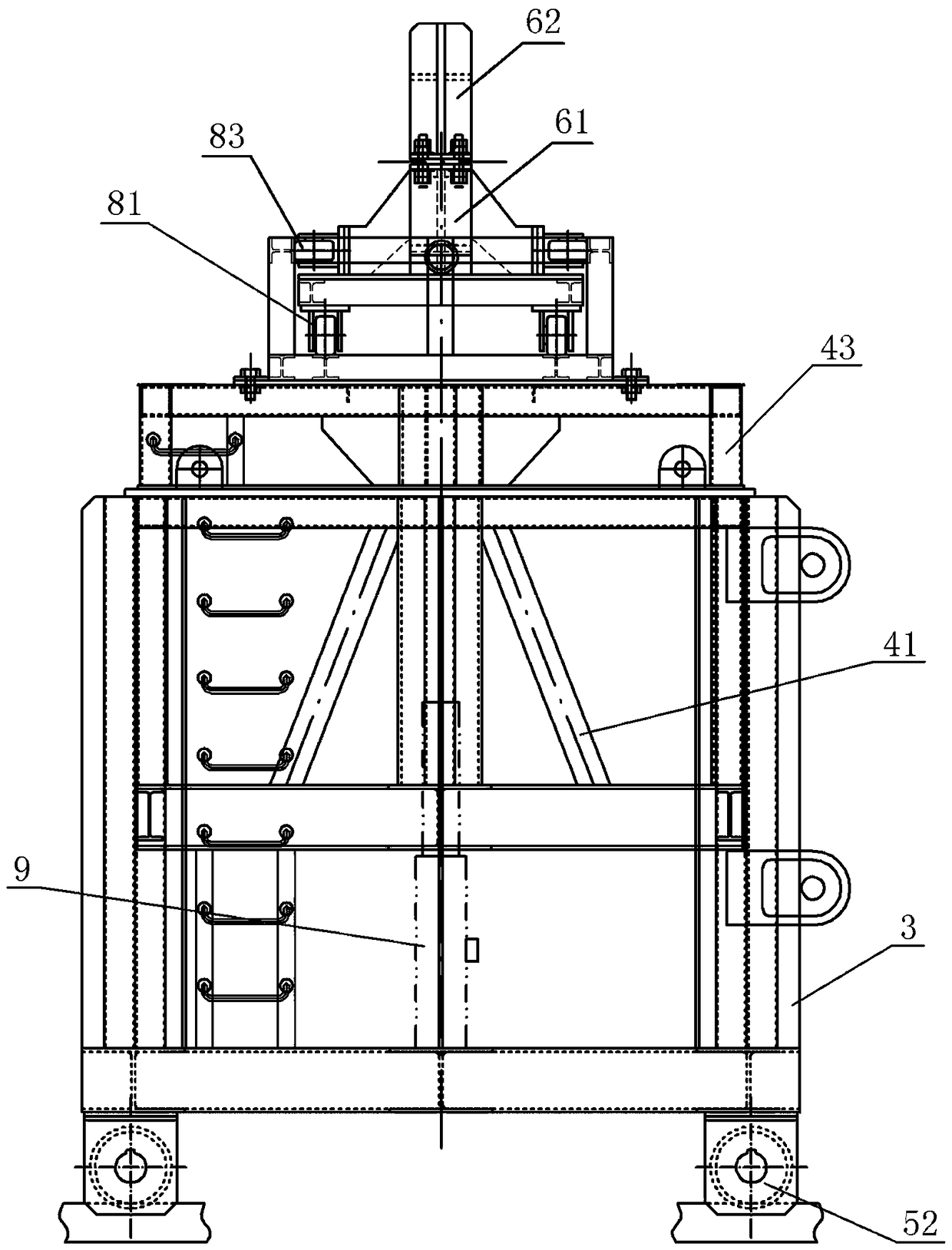

[0021] A ship stern shaft installation device, comprising a supporting trolley 1 supporting the tail end of the stern shaft 100, and a guiding trolley 2 guiding the front end of the stern shaft; The bottom of the car base is installed with a wheel assembly that drives the car base to move; the top of the jacking assembly that supports the trolley is installed with a clamp assembly that clamps and fixes the stern shaft, and the top of the jacking assembly that guides the trolley is installed. There is a roller assembly supporting the stern shaft; in addition, a lateral adjustment assembly for horizontally adjusting the clamp assembly and the roller assembly is respectively installed on the car base of the supporting trolley and the guiding trolley.

[0022] In the ship stern shaft installation device, the jacking assembly includes a jacking frame 41 that moves up and down along the vehicle base 3 and a jacking driver 42 that drives the jacking frame to move, and the top of the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com