Preparation method of modified nano calcium carbonate

A nano-calcium carbonate, modified technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, chemical instruments and methods, etc., can solve the unfavorable production efficiency and yield of nano-calcium carbonate, the failure of nano-calcium carbonate production, and the large number of preparation equipment and other issues, to achieve the effect of improving production efficiency and production quality standards, reducing preparation equipment, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

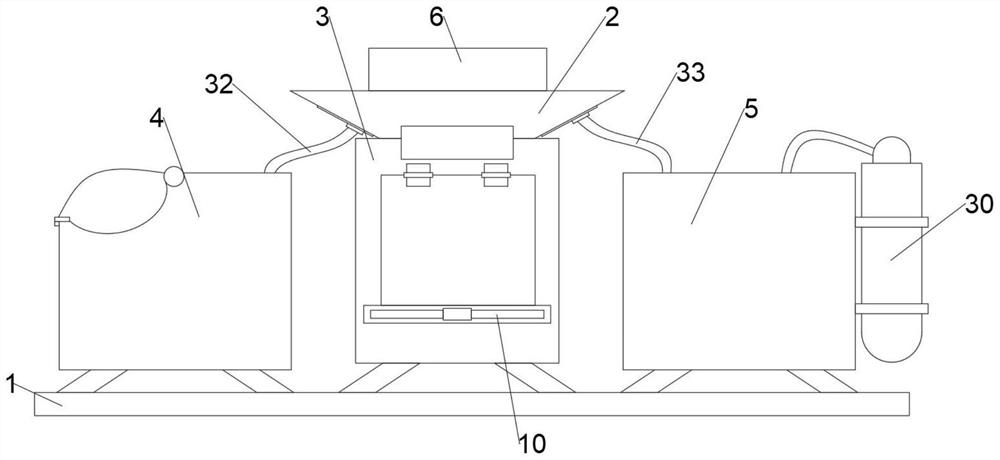

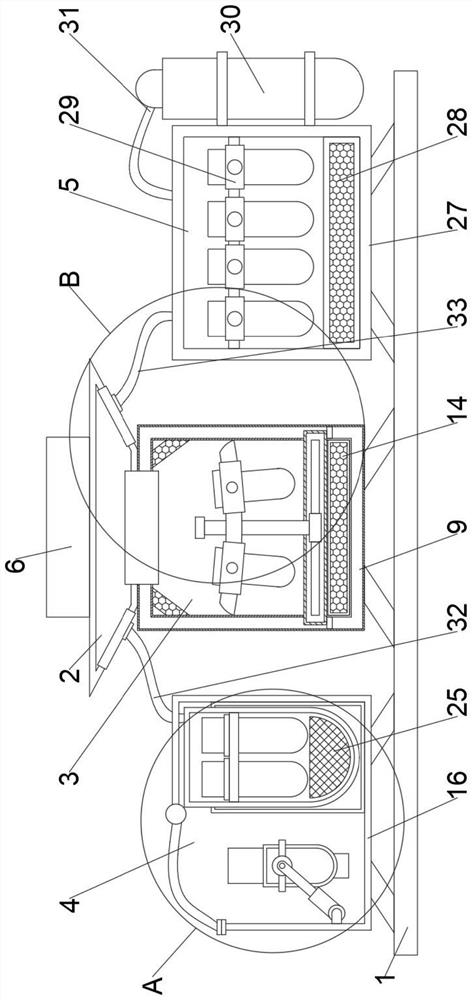

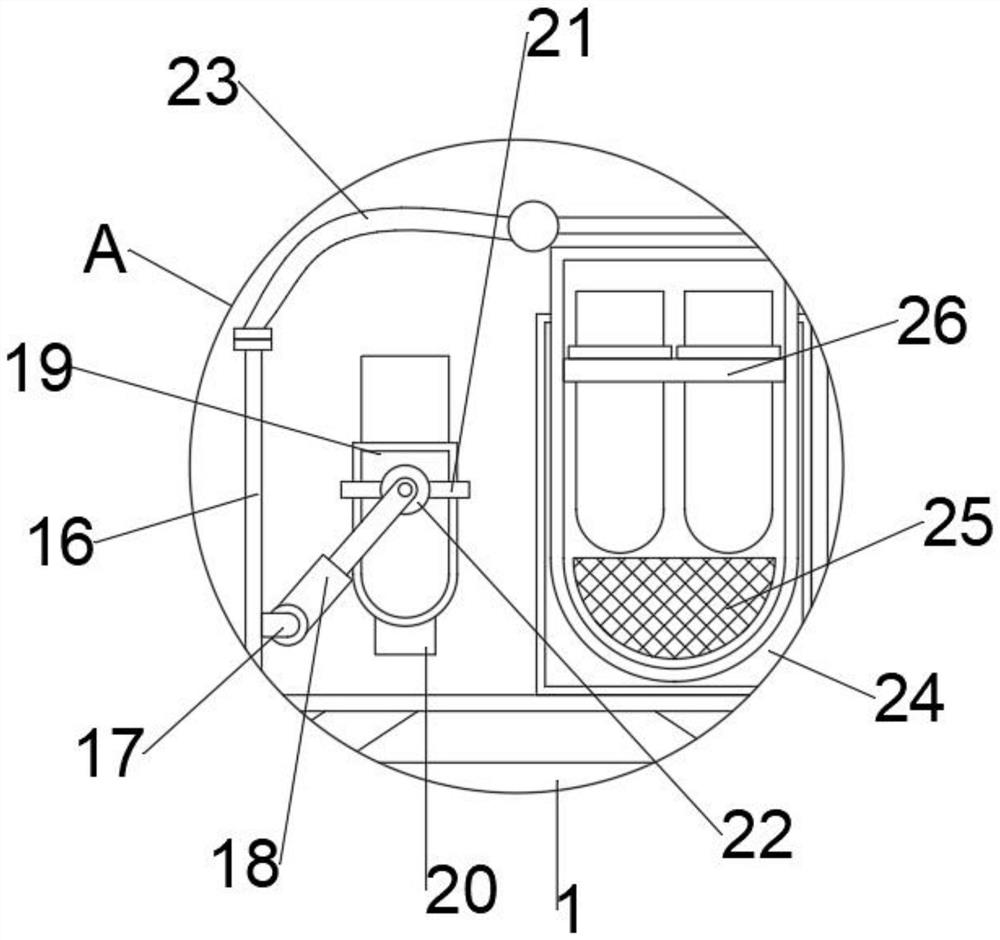

Image

Examples

Embodiment 1

[0032] A kind of preparation method of modified nanometer calcium carbonate that the present invention proposes, comprises the following steps:

[0033] S1. Quicklime and water are mixed in proportion, and a chelating agent is added to react to prepare lime slurry. The lime slurry is shaken, and the solid particle content of the lime slurry is adjusted to 10%;

[0034] S2, preparing a modifier; preparing vinyltriethoxysilane, phosphoric acid ester and deionized water according to the ratio of 6:1:3 to form an ionic surfactant;

[0035] S3, adding the ionic surfactant prepared in S2 into the lime slurry prepared in S1, and shaking the mixed solution;

[0036] S4, the mixed solution that the S3 shock finishes is left standstill, and carbon dioxide is added in the solution after standing, and the solution is gasified, thereby preparing nano-calcium carbonate suspension;

[0037] S5. Drying the nano-calcium carbonate suspension, grinding and filtering the dried particles, and obt...

Embodiment 2

[0039] A kind of preparation method of modified nanometer calcium carbonate that the present invention proposes, comprises the following steps:

[0040] S1. Utilize unslaked lime and water to mix in proportion, add chelating agent, react and prepare lime slurry, shake the lime slurry, and adjust the solid particle content of the lime slurry to 12%;

[0041] S2, preparing a modifier; preparing vinyltriethoxysilane, phosphoric acid ester and deionized water according to the ratio of 4:3:3 to form an ionic surfactant;

[0042] S3, adding the ionic surfactant prepared in S2 into the lime slurry prepared in S1, and shaking the mixed solution;

[0043] S4, the mixed solution that the S3 shock finishes is left standstill, and carbon dioxide is added in the solution after standing, and the solution is gasified, thereby preparing nano-calcium carbonate suspension;

[0044] S5. Drying the nano-calcium carbonate suspension, grinding and filtering the dried particles, and obtaining nano-...

Embodiment 3

[0046] A kind of preparation method of modified nanometer calcium carbonate that the present invention proposes, comprises the following steps:

[0047] S1, using quicklime and water to mix in proportion, adding a chelating agent, reacting to prepare lime slurry, shaking the lime slurry, and adjusting the solid particle content of the lime slurry to 15%;

[0048]S2, preparing a modifier; preparing vinyltriethoxysilane, phosphoric acid ester and deionized water according to the ratio of 7:2:1 to form an ionic surfactant;

[0049] S3, adding the ionic surfactant prepared in S2 into the lime slurry prepared in S1, and shaking the mixed solution;

[0050] S4, the mixed solution that the S3 shock finishes is left standstill, and carbon dioxide is added in the solution after standing, and the solution is gasified, thereby preparing nano-calcium carbonate suspension;

[0051] S5. Drying the nano-calcium carbonate suspension, grinding and filtering the dried particles, and obtaining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com