A hanging glass inner curtain wall

A hanging and glass technology, applied in the direction of walls, buildings, building components, etc., can solve problems such as difficulty in ensuring the verticality of glass panels, achieve good application prospects, not easy to dump, and easy to disassemble and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

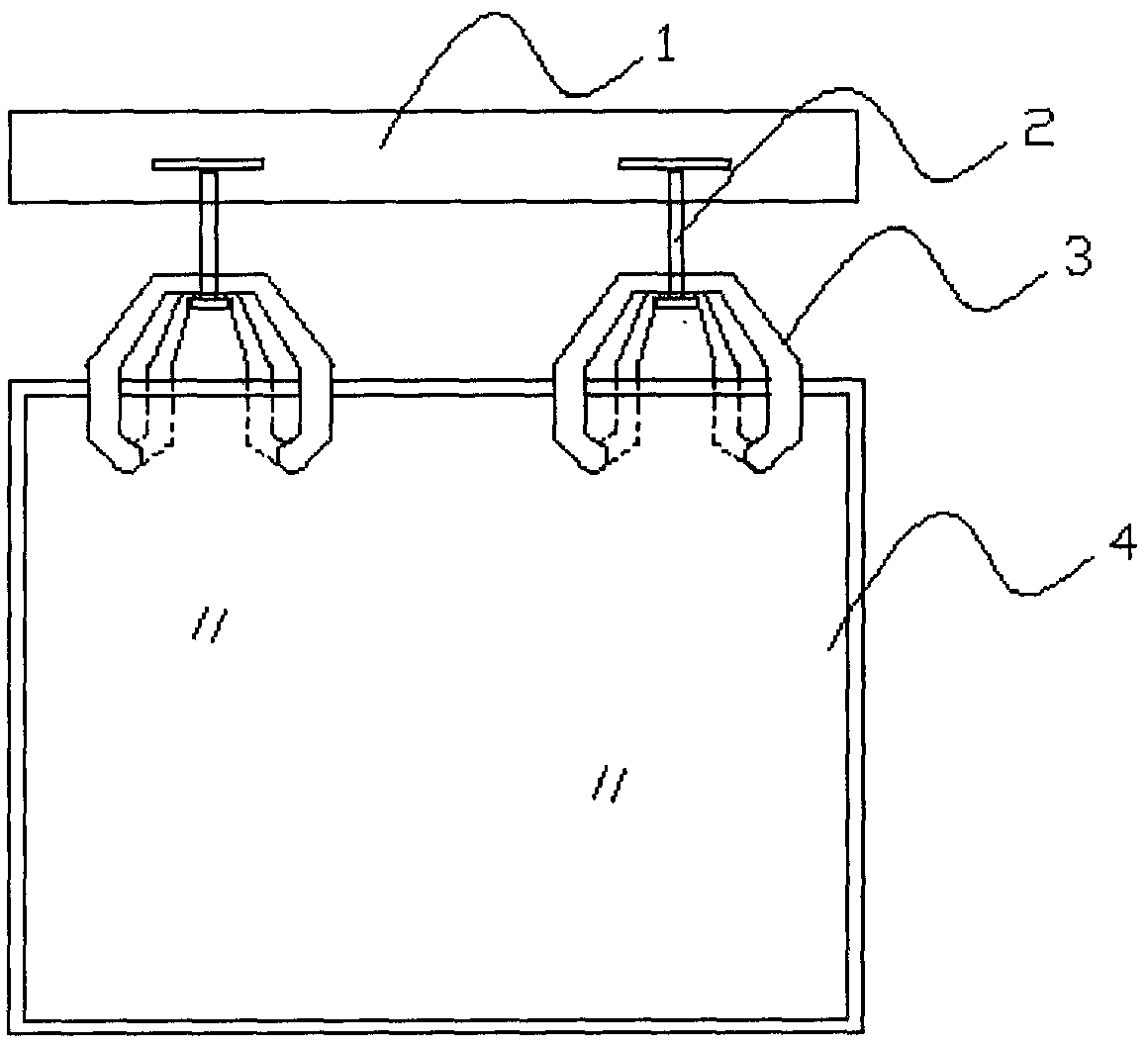

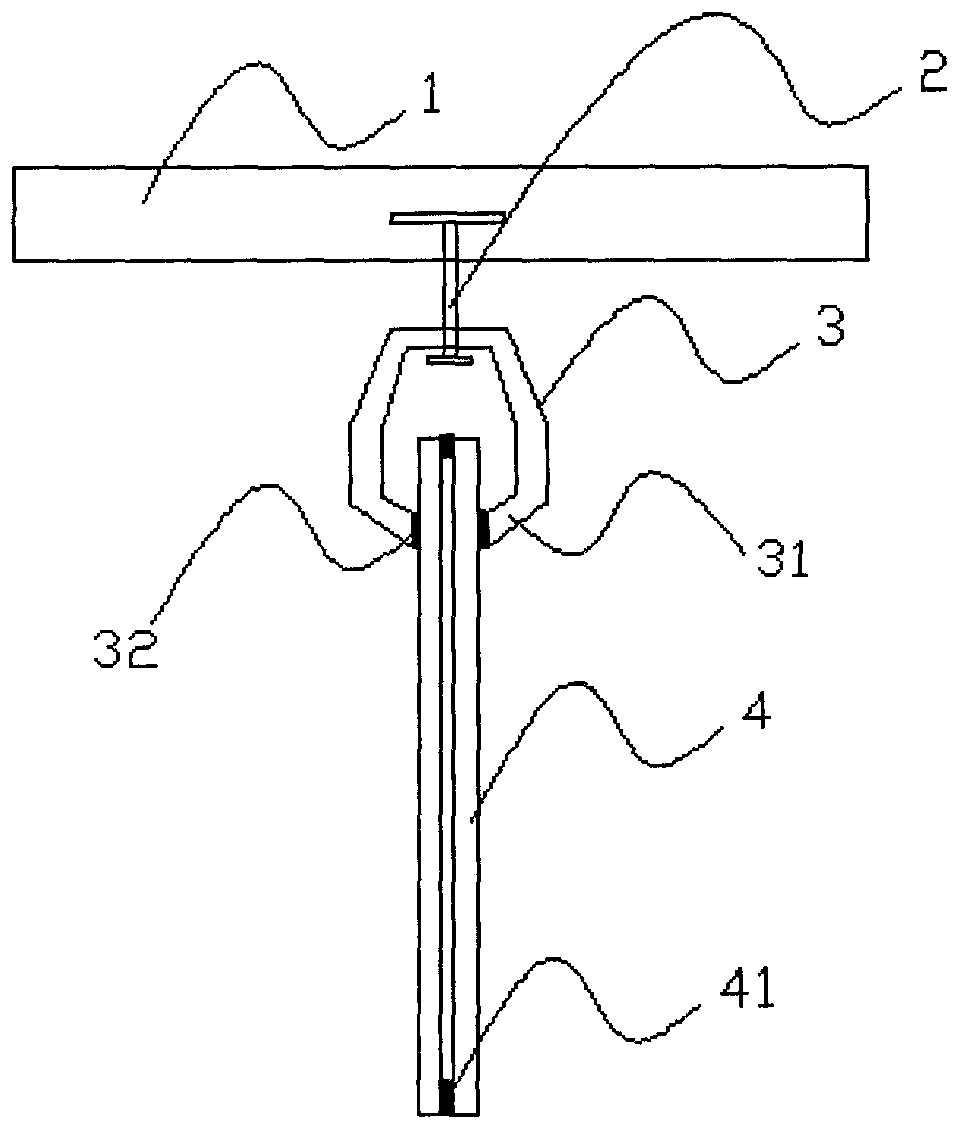

[0022] Such as Figures 1 to 2 As shown, a suspended glass inner curtain wall includes a suspender 2, a suspension part 3 and a glass panel 4. The upper end of the suspender 2 is pre-buried in the ceiling 1, and the lower end is connected with the suspension part 3. The suspension part 3 is fixedly connected with the upper end of the glass panel 4 . The upper end of the glass panel 4 is fixed by a plurality of suspension components 3 .

[0023] The hanging part 3 is a hanging claw, and the hanging claw is provided with four claw parts 31 , and the claw parts 31 are connected with the glass panel 4 through structural glue 32 .

[0024] The glass panel 4 is made of double-layer glass, the middle of the double-layer glass is a vacuum, and the surrounding is sealed by a sealant 41 .

[0025] The double-layer glass of the glass panel 4 is a whole piece of glass.

Embodiment 2

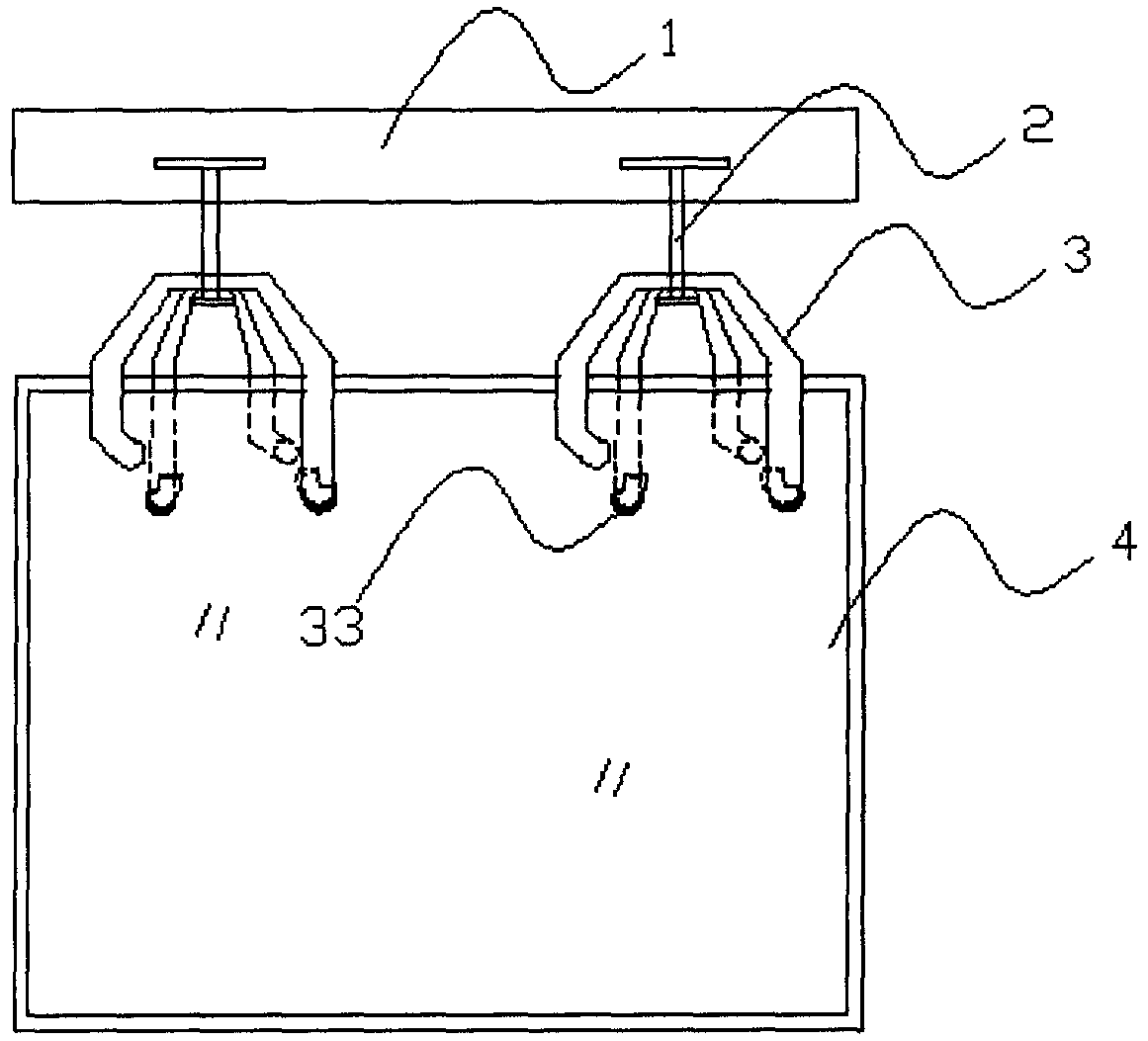

[0027] Such as Figures 3 to 4 As shown, a suspended glass inner curtain wall, its structure is basically similar to that of Embodiment 1, the difference is that: the upper end of the glass panel 4 is provided with two through holes 33, and the hook portion 31 passes through the glass panel 4 The through hole 33 on the top, the contact surface of the hook portion 31 passing through the through hole 33 and the through hole 33 is connected by structural glue 32 .

Embodiment 3

[0029] Such as Figures 5 to 6 As shown, a suspended glass inner curtain wall includes a suspender 2, a suspension part 3 and a glass panel 4. The upper end of the suspender 2 is pre-buried in the ceiling 1, and the lower end is connected with the suspension part 3. The suspension part 3 is fixedly connected with the upper end of the glass panel 4 .

[0030] The hanging component 3 is provided with a mounting groove 34 , and the mounting groove 34 is fixedly connected with the upper end of the glass panel 4 .

[0031] The inner surface of the installation groove 34 is connected with the outer surface of the glass panel 4 through structural glue 32 . In addition, the installation groove 34 and the glass panel 4 may also be connected by bolts.

[0032] The glass panel 4 is made of double-layer glass, the middle of the double-layer glass is a vacuum, and the surrounding is sealed by a sealant 41 .

[0033] The double-layer glass of the glass panel 4 is a whole piece of glass. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com