Integrated prefabricated giant column steel formwork support system

A technology of steel formwork and giant columns, which is applied in the field of integrated prefabricated giant column steel formwork support systems, which can solve the problems of verticality and flatness of structural columns, high technical requirements for formwork reinforcement, and low installation and removal efficiency and other problems, to achieve the effect of safety and quality inspection and control, which is easy to control, simplifies the surface treatment in the later stage, and is simple to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

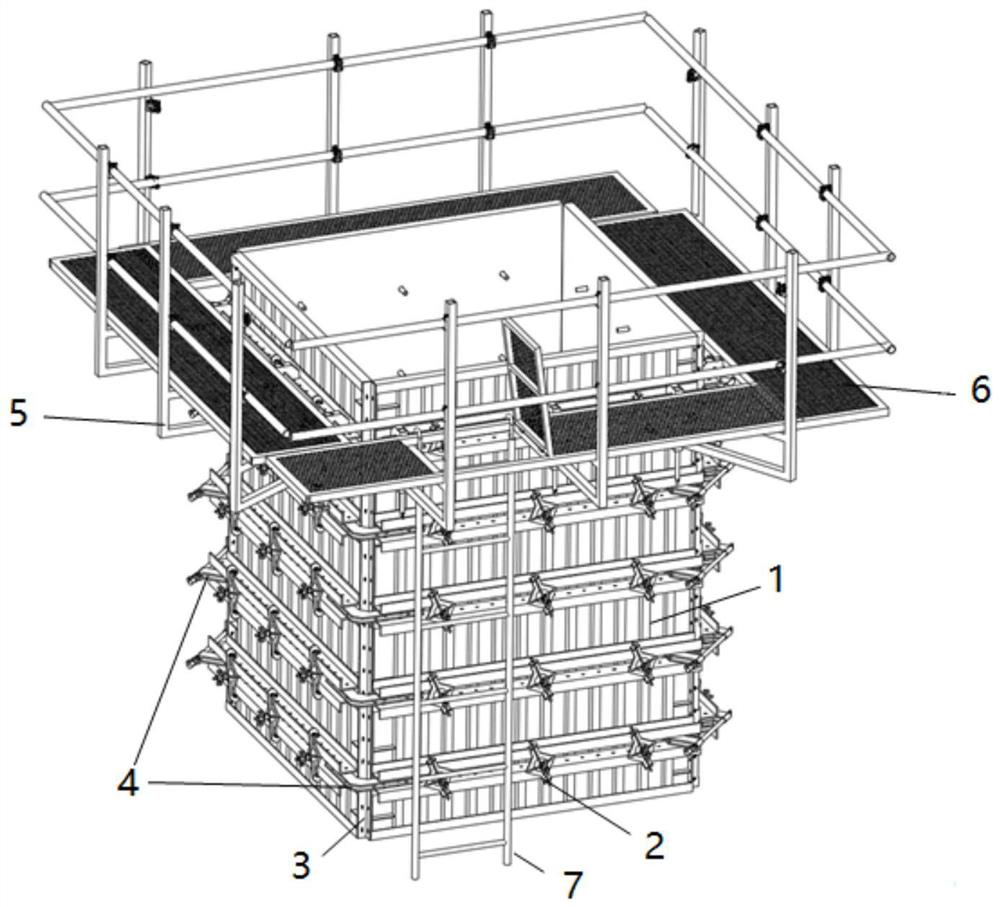

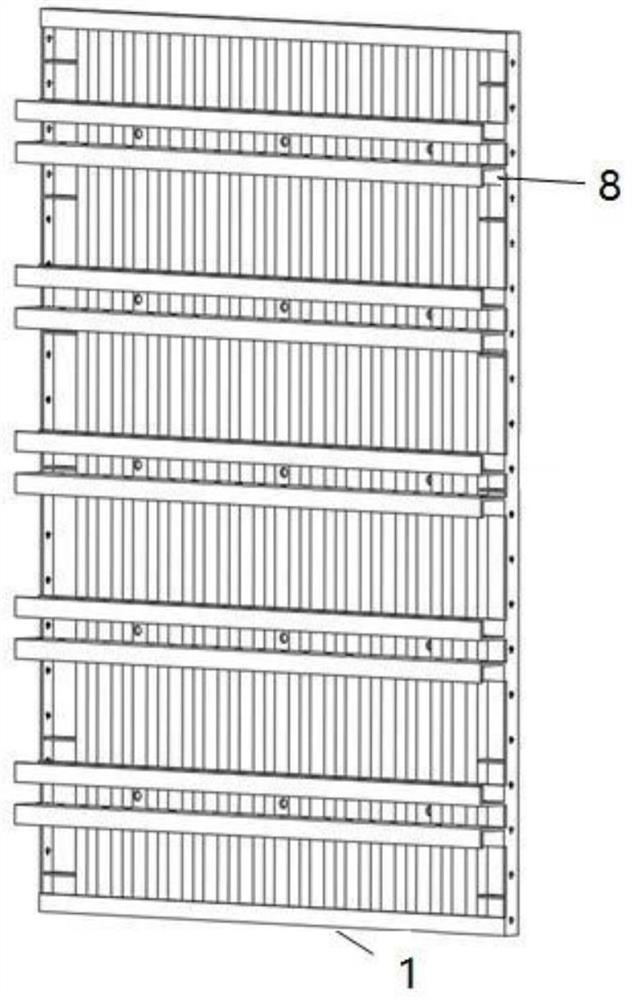

[0054] see figure 1 , the present invention provides an integrated prefabricated giant column steel formwork support system, including a steel formwork 1 hoisted and installed outside the vertical steel bars of a structural column, and reinforced by a combination of pulling screws 2; the width of a single piece of steel formwork 1 depends on the column The size of the steel bar is determined, the main body of the steel formwork 1 is a steel plate, several vertical and evenly distributed vertical keels are welded on the steel plate, and a number of channel steel groups 8 arranged at intervals up and down are welded on one side of the steel plate as the main keel in the horizontal direction. , one side of the steel formwork 1 is welded with an angle steel 3 for connecting with the adjacent steel formwork 1, and the channel steel groups 8 of the adjacent two steel formwork 1 are fixedly connected by the reinforcement 4;

[0055] A number of pedal supports 5 are connected around t...

Embodiment 2

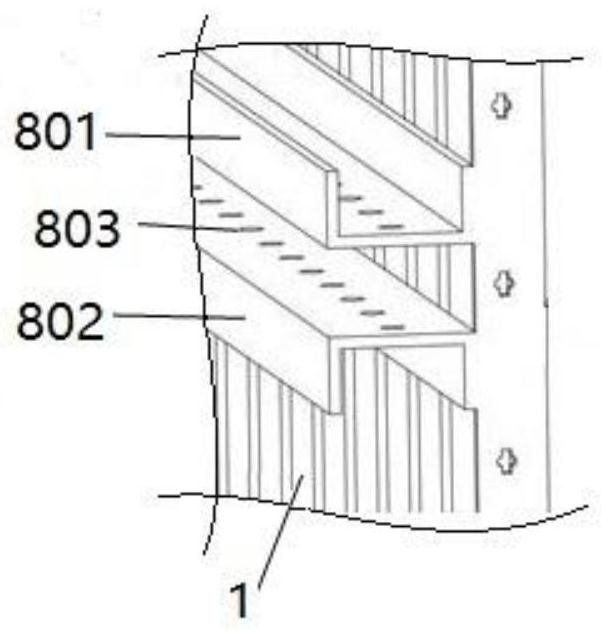

[0057] see figure 1 , image 3 , Image 6 , Figure 7 , on the basis of Embodiment 1, the channel steel group 8 includes an upper channel steel 801 and a lower channel steel 802, the groove of the upper channel steel 801 is upward, and the groove of the lower channel steel 802 is downward;

[0058] There are several evenly distributed connecting holes 1 301 on both sides of the angle steel 3, which are used to install triangle iron or bolts; there are several evenly distributed connecting holes 803 on the webs of the upper channel steel 801 and the lower channel steel 802. to install firmware 4.

[0059] The height of a single steel formwork is 3m; the thickness of the steel plate is 5mm; the vertical keel is made of square steel with a spacing of 5cm*5cm and a spacing of 20cm; the size of the channel steel group is 65*125*8mm; the spacing between adjacent connecting holes is 15cm; The diameter of the first one is 18-20mm, generally 20mm; the distance between the two adjac...

Embodiment 3

[0065] see Figure 4 to Figure 5 , on the basis of Embodiment 1, the pair of pull-screw combination 2 includes a connecting rod 201, a reinforcing backing plate 204 and a nut 205; one end of the connecting rod 201 is set as an external connector 202, and the other end is set with a threaded rod. The end is provided with a pair of pull-screw connection grooves 203, the inner wall of the pull-screw connection groove 203 is provided with threads, the pair of pull-screw is threadedly connected to the external connector 202 through the pair of pull-screw connection grooves 203, and the threaded rod passes through the reinforcement backing plate 204 and the nut 205. threaded connection;

[0066] "J"-shaped hooks 206 are symmetrically arranged on both sides of the reinforcing pad 204 , and grooves are formed in the hooks 206 corresponding to the edges of the upper channel steel 801 and the lower channel steel 802 .

[0067] The length of the connecting rod is 380mm, the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com