Patents

Literature

58results about How to "Flatness is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

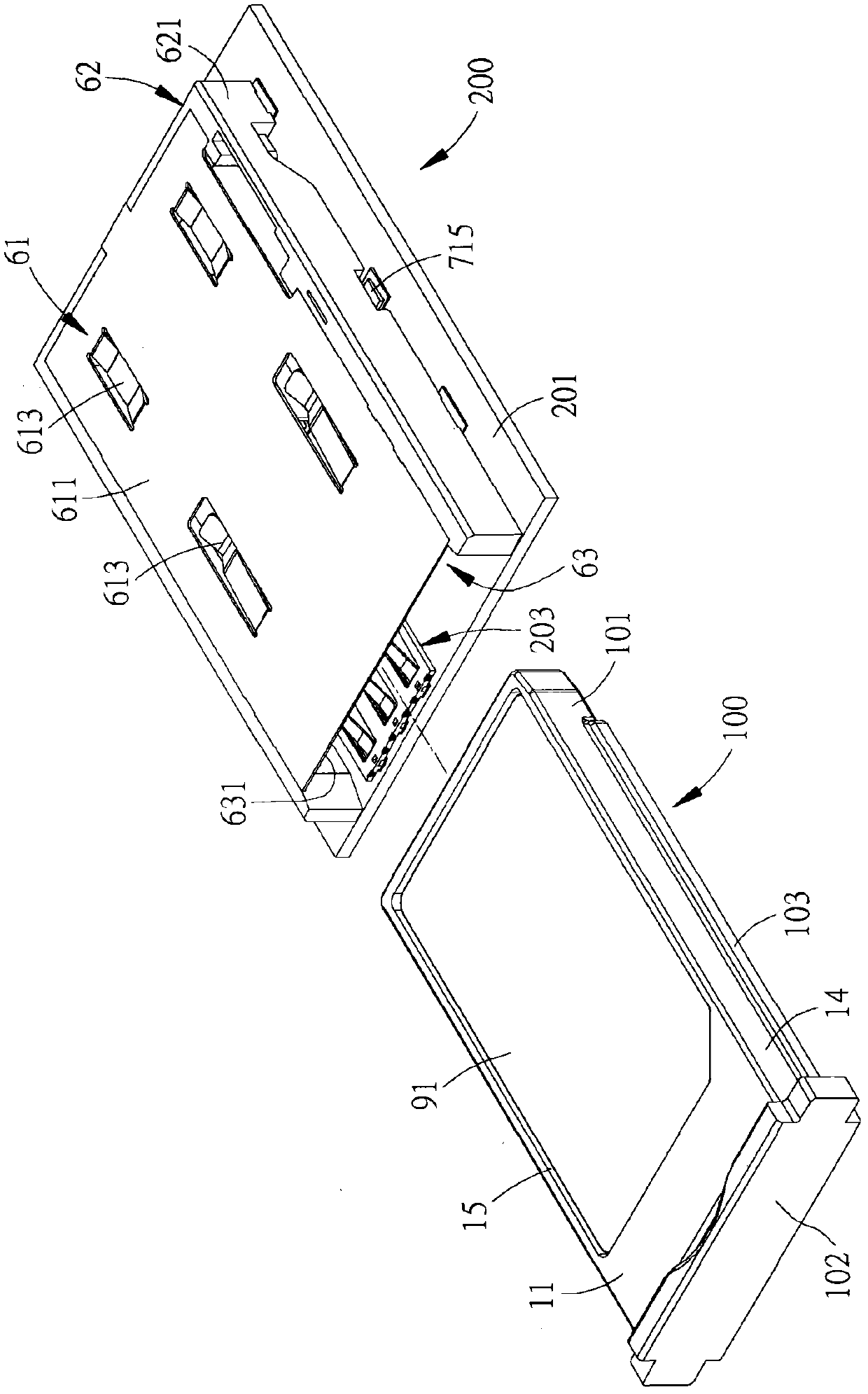

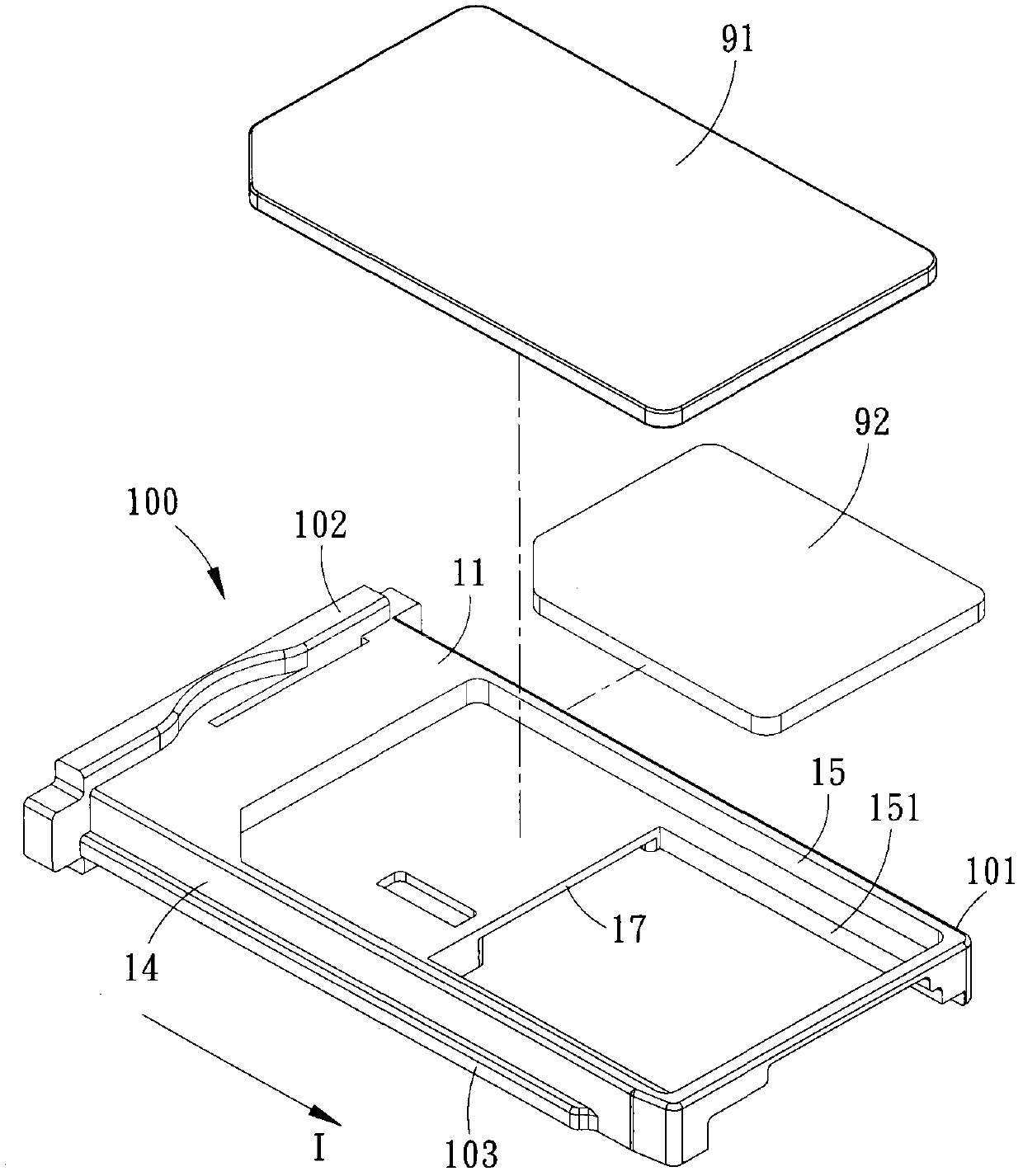

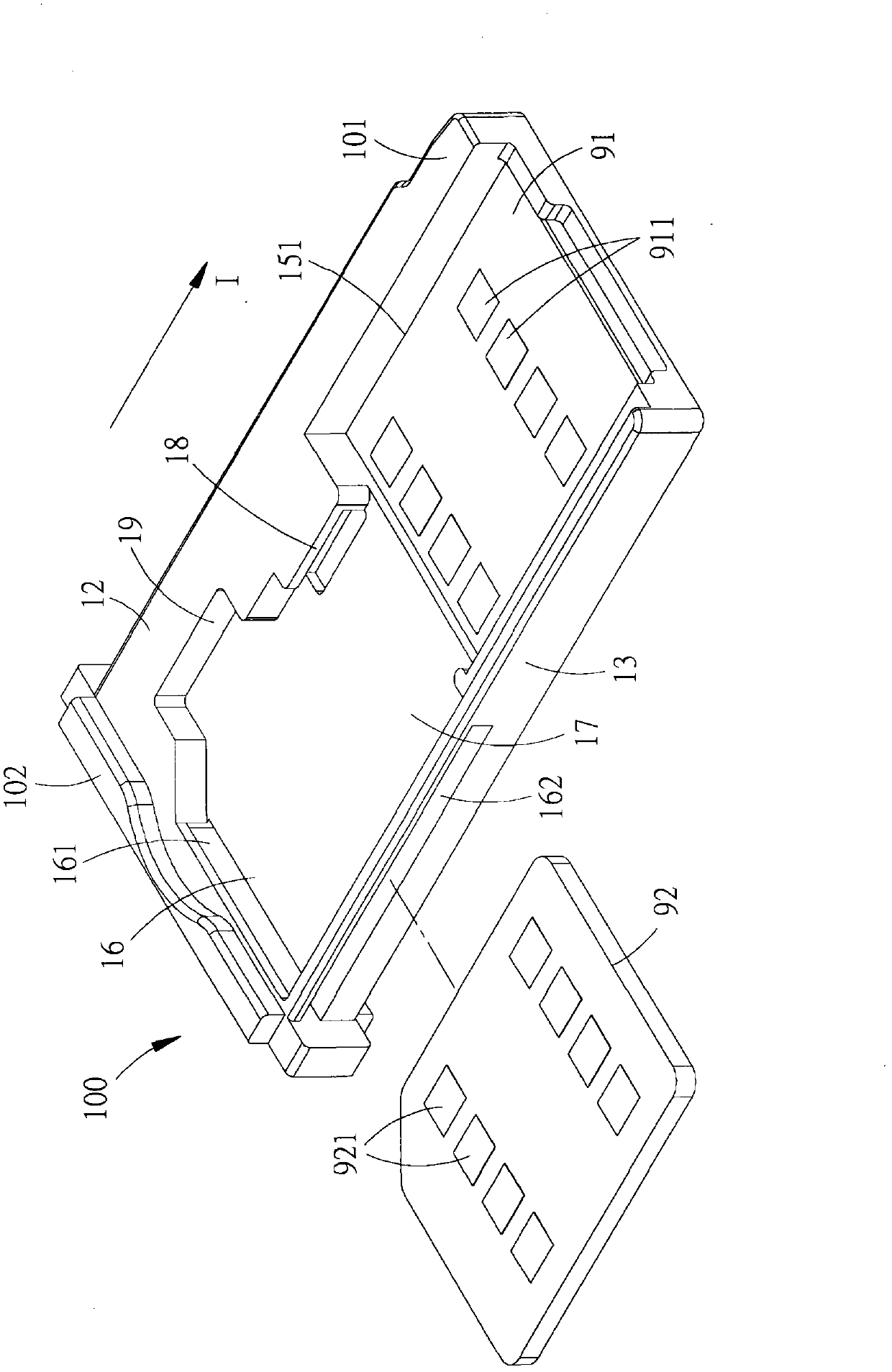

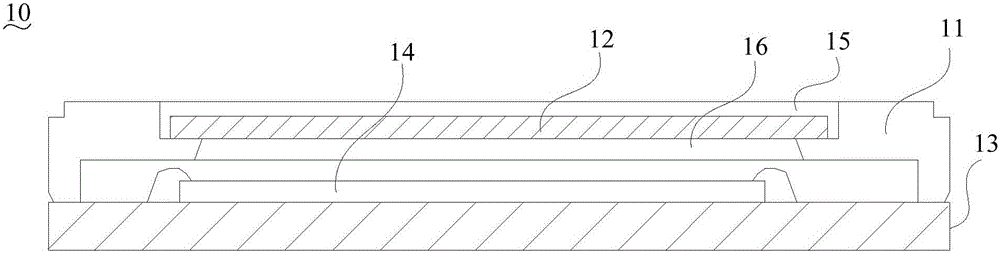

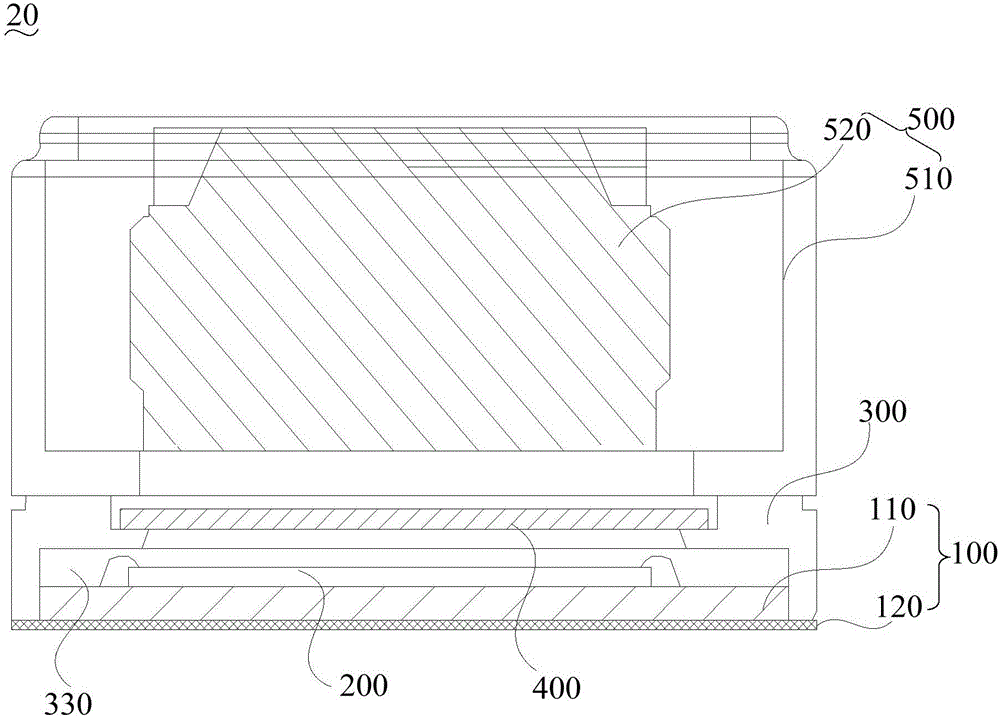

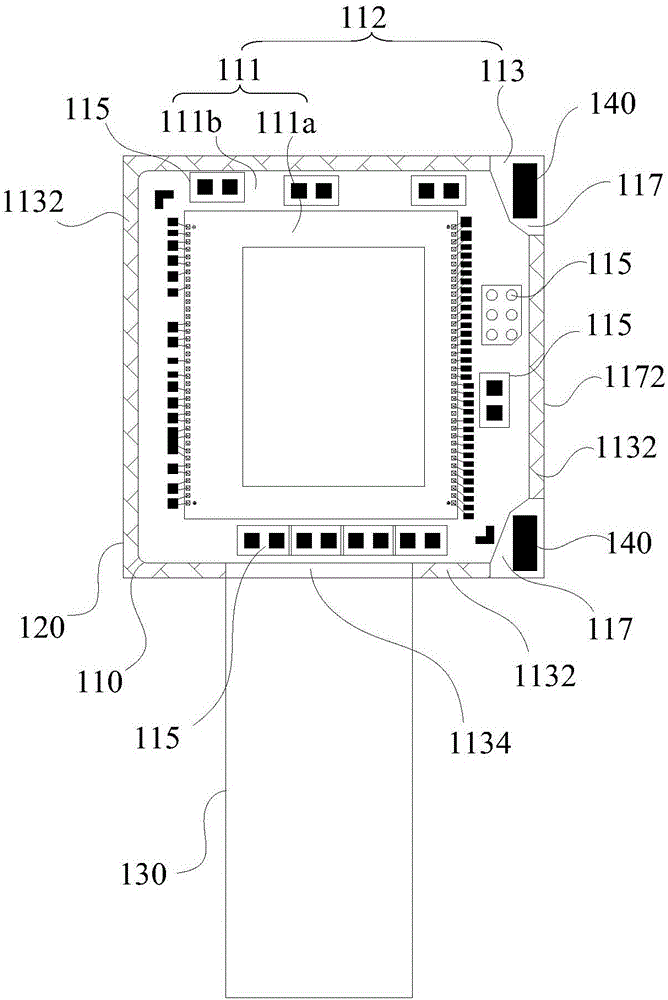

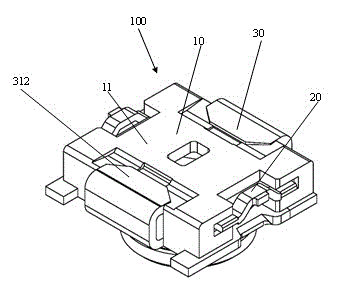

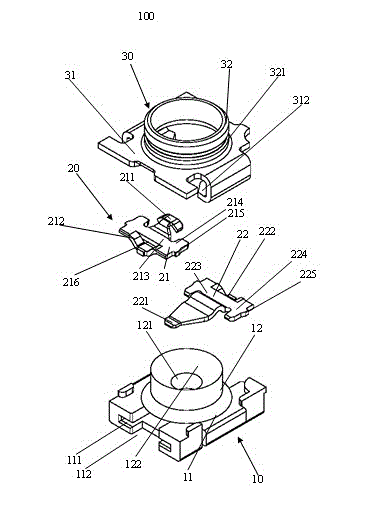

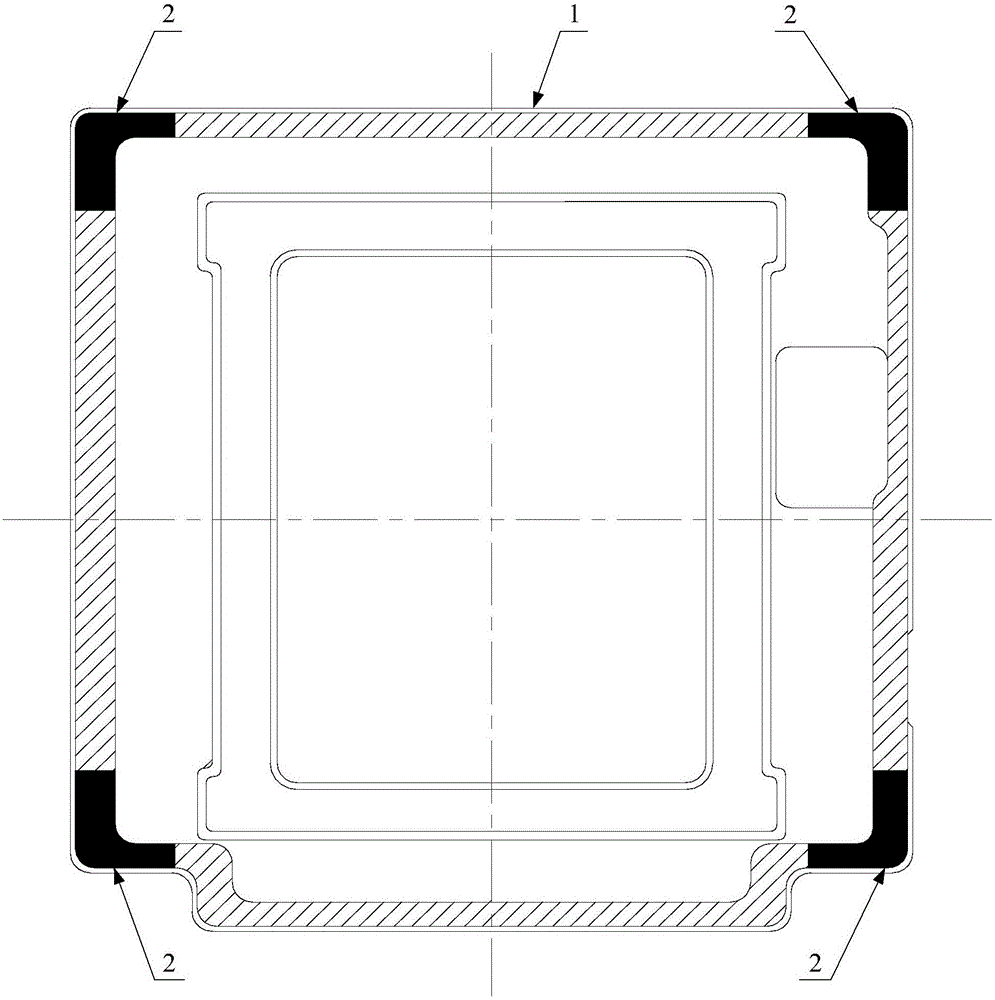

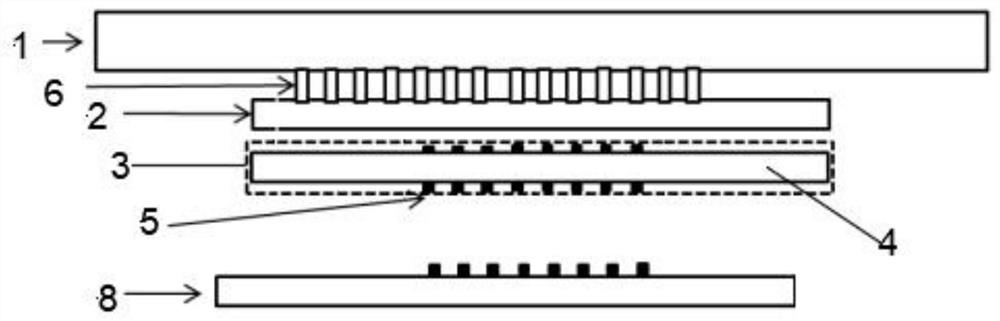

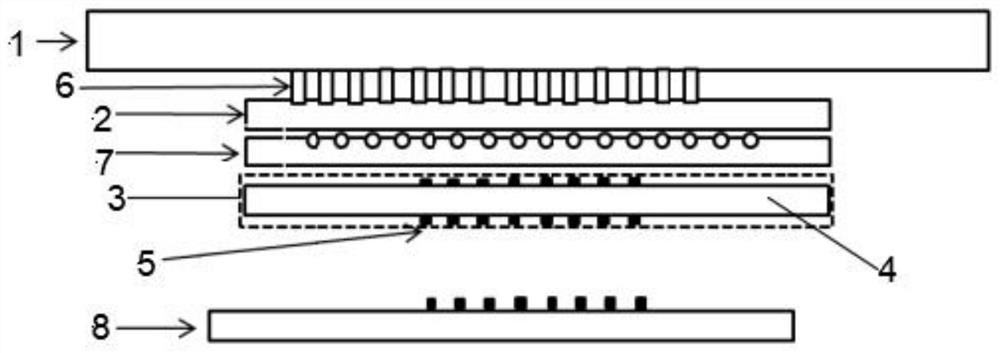

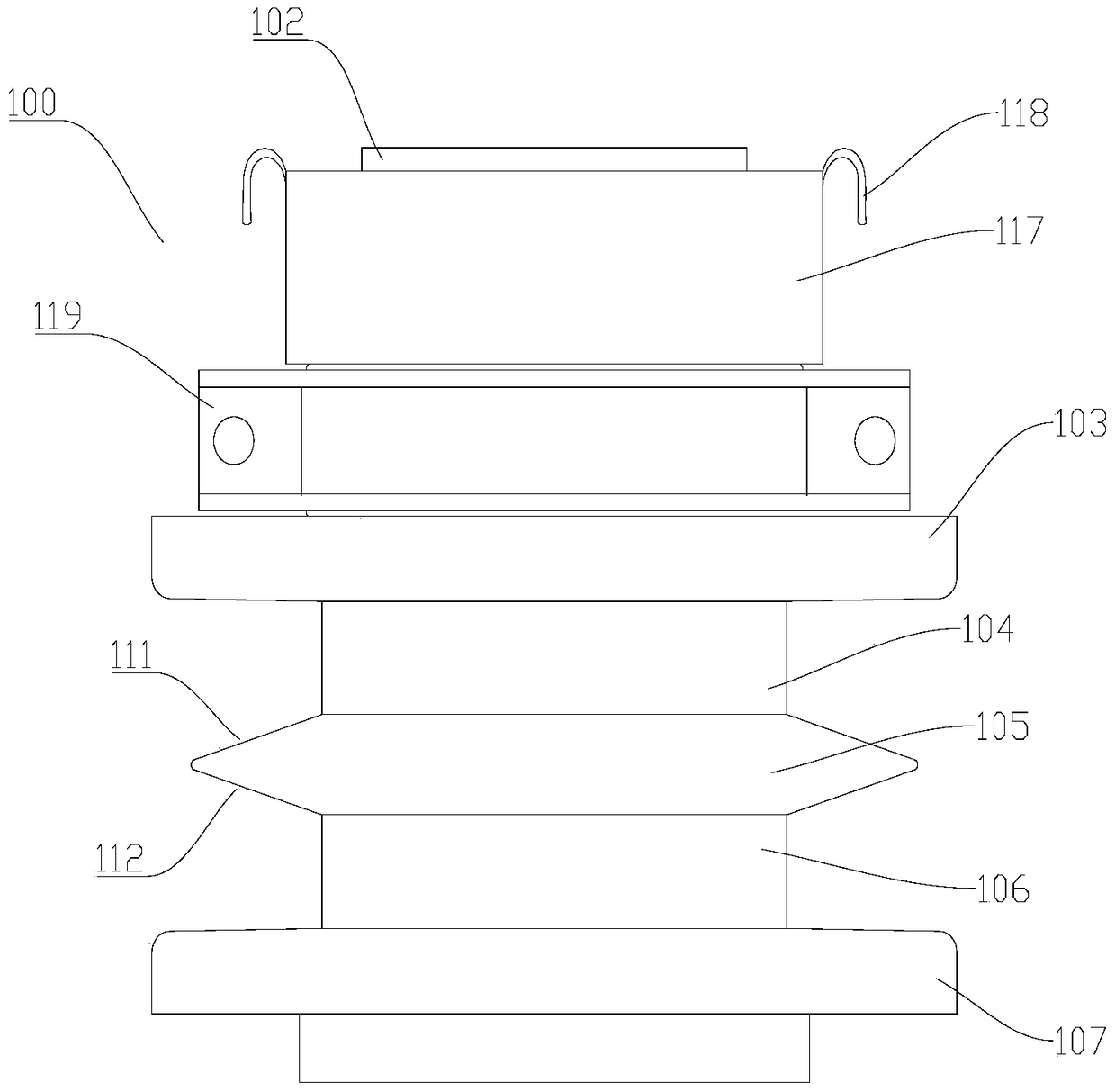

Dual SIM (Subscriber Identity Module)-card tray, connector module and electrical connector device

InactiveCN103311721ASmall space volumeFlatness is easy to controlIncorrect coupling preventionSensing record carriersElectrical connectorEmbedded system

The invention discloses a dual SIM (Subscriber Identity Module)-card tray, a connector module and an electrical connector device. The electrical connector device comprises a tray and a connector module, wherein the main body of the tray is provided with a first accommodating groove and a second accommodating groove which are positioned on two opposite sides and are used for accommodating a small-sized SIM card and a micro SIM card respectively, and is provided with a first window communicated with the first accommodating groove and a second window communicated with the second accommodating groove; the first window and the second window are arranged along the length direction of the tray, so that conducting pads of the two SIM cards are exposed towards the same side; the connector module comprises a circuit board, a first connector, a second connector and a shell; the first connector and the second connector are arranged separately on the circuit board to be electrically connected with the two SIM cards respectively and correspondingly; and the shell is arranged on the circuit board, covers the first connector and the second connector, and defines an insertion space for accommodating the tray.

Owner:MOLEX INTERCONNECT (CHENGDU) CO LTD +1

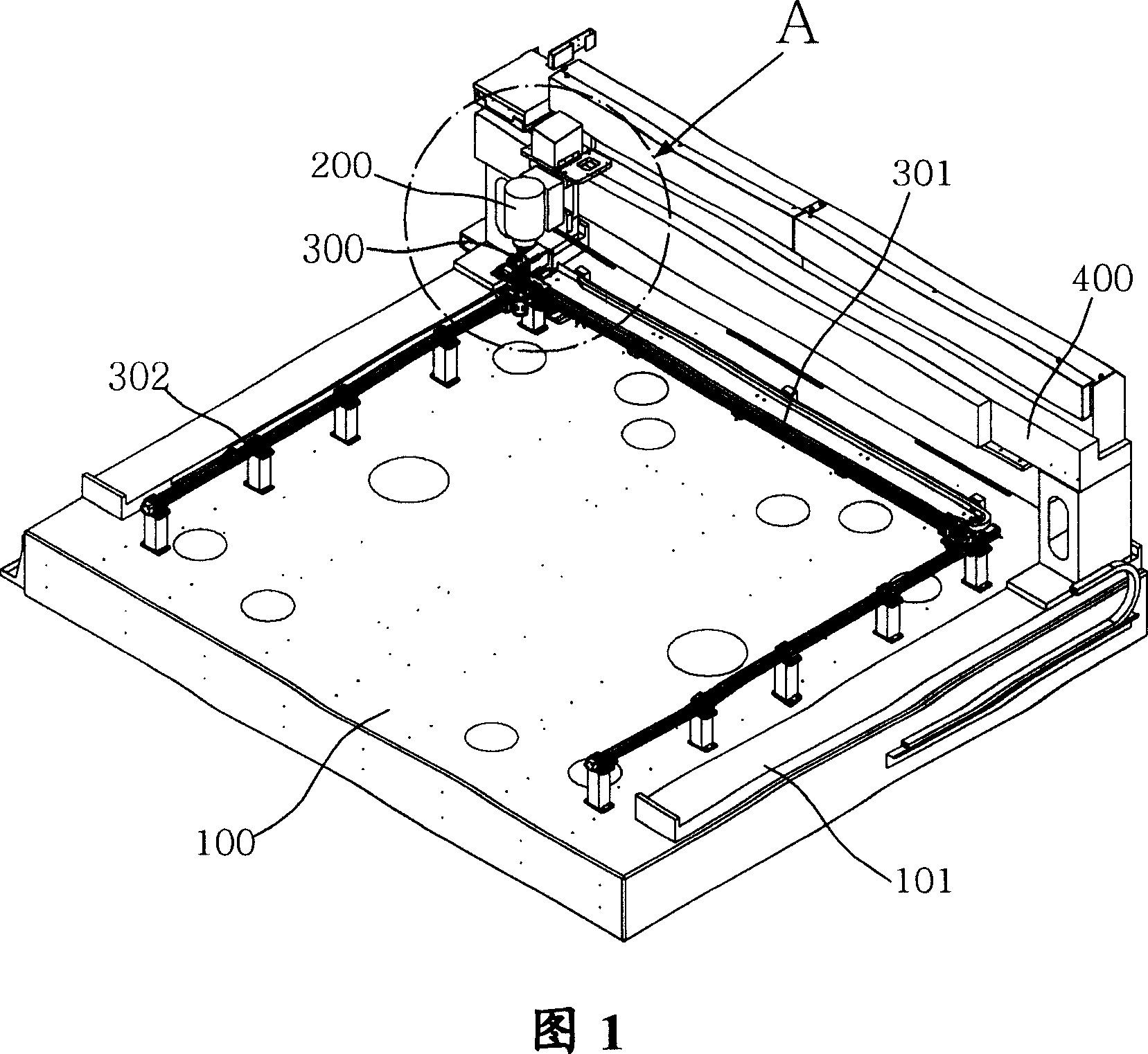

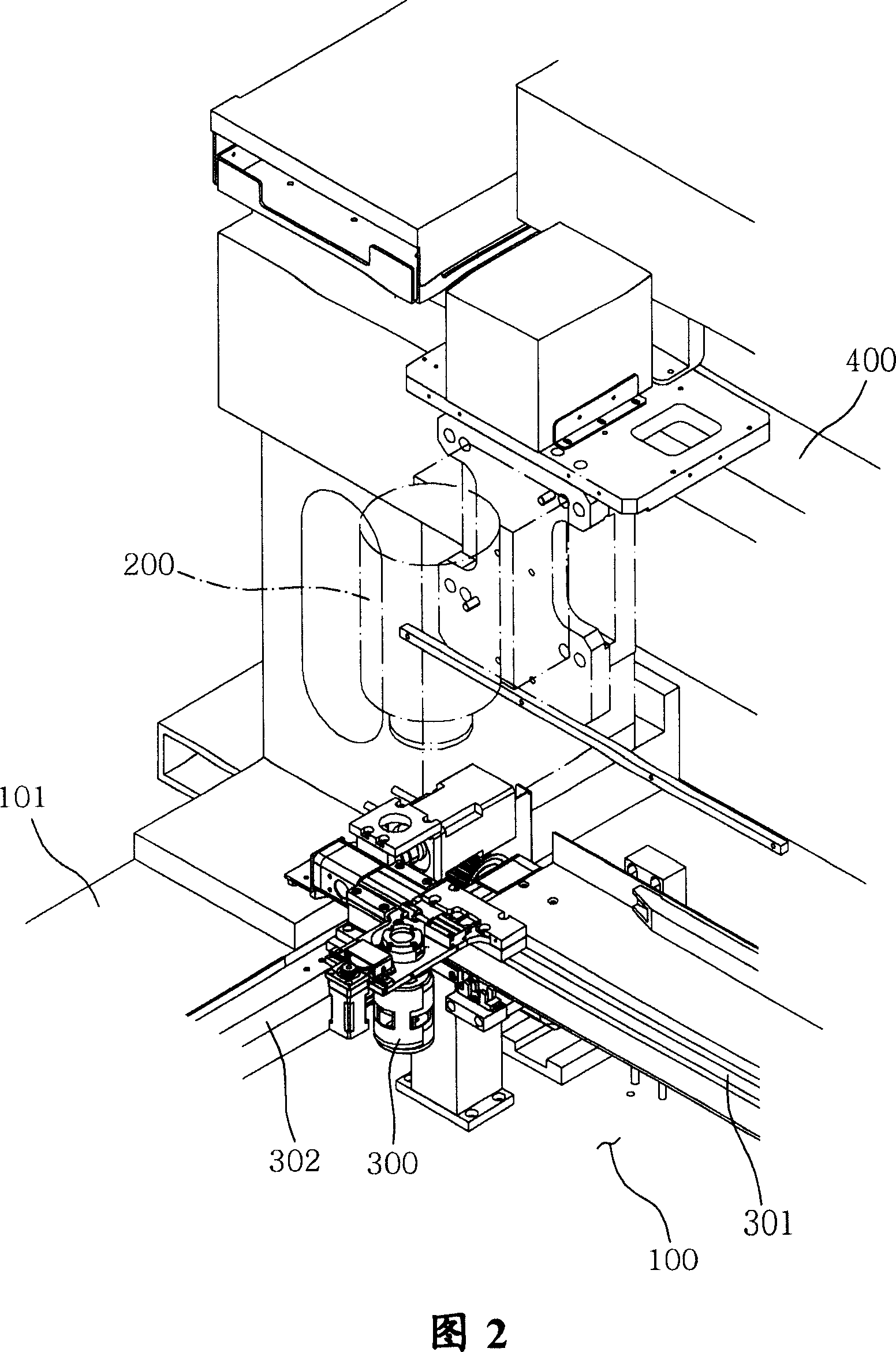

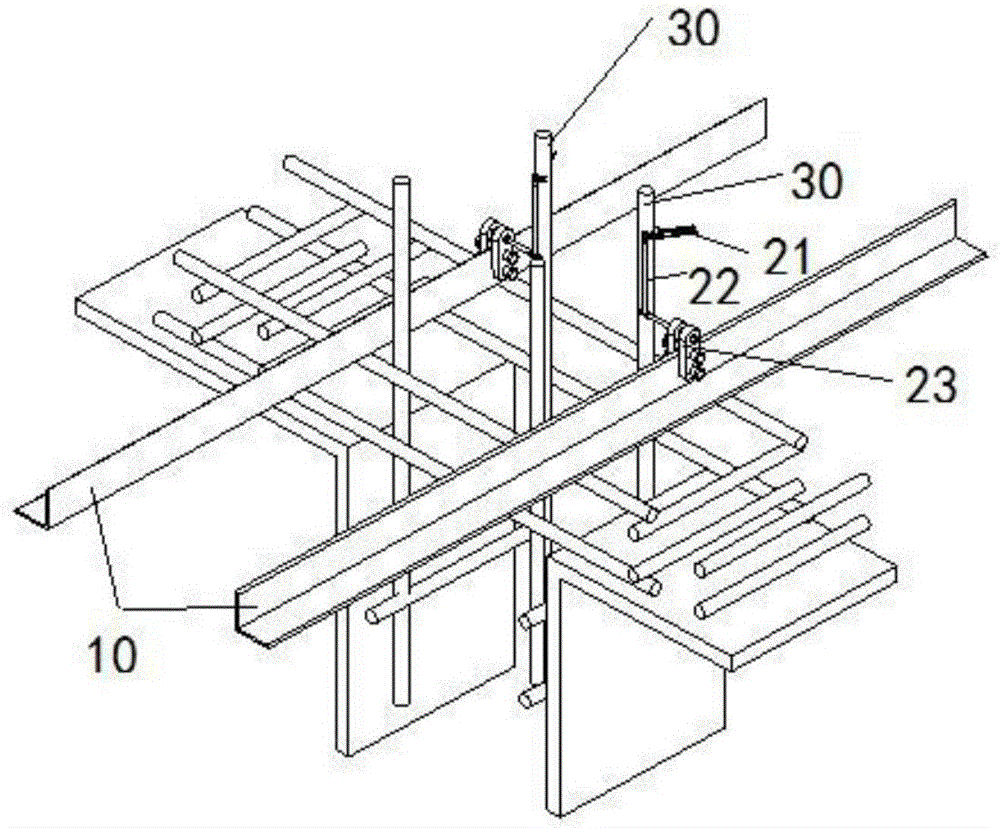

Microcosmic checking device for glass panel

InactiveCN1924513ALess dark spotsStable supportElectric discharge tubesMaterial analysis by optical meansLiquid-crystal displayMicroscopic scale

Disclosed is a microcosmic checking device for detecting the glass panel used in FPD such as LCD and PDP. The microcosmic checking device comprises: a worktable, wherein a glass panel is fixed; a microscope and a light source lamp above and below the work table for detecting the defects of the glass panel; and a driving unit for moving the microscope and light along X axis and Y axis. The driving unit comprises: a bridge, wherein the microscope and the light source lamp are mounted apart on the top or bottom, the bridge is movably connected to the surface table track formed along the relative sides of the surface table, which constitutes the main body of the microcosmic checking device; a forwards and backwards driving unit for moving the bridge along the surface table track; and leftwards and rightwards driving unit for moving the microscope and light source lamp simultaneously along the left axis and the right axis.

Owner:DE&T

Water-borne polyurethane synthetic leather size and preparation method and application thereof

InactiveCN102863605AHigh peel strengthModerate resilienceTextiles and paperCross-linkPolymer science

The invention discloses a water-borne polyurethane synthetic leather size and a preparation method and an application thereof. The water-borne polyurethane synthetic leather size comprises diisocyanate, poly dibasic alcohol, phosphoric acids, catalysts, hydrophilic chain extenders, neutralizers, small molecule chain extenders or cross-linking agents, surface active agents and the like. The preparation method of the water-borne polyurethane synthetic leather size includes (1) polymerizing the diisocyanate, the poly dibasic alcohol and the phosphoric acids under the action of the catalysts; (2) adding the hydrophilic chain extenders for chain extension; (3) cooling and neutralizing a reaction solution, and continuing the reaction by adding the small molecule chain extenders or cross-linking agents and the surface active agents; and (4) emulsifying and adding auxiliaries to uniformly stir. According to the water-borne polyurethane synthetic leather size and the preparation method and the application thereof, the phosphoric acids are added in the formula, the wettability of the ultimately prepared synthetic leather size and non-woven fabrics is improved, further the process for preparing the synthetic leather can be simplified, properties of the prepared synthetic leather are improved, simultaneously the feed ratio of the diisocyanate and the poly dibasic alcohol is strictly controlled, and the ultimately prepared synthetic leather has the advantages that the peel strength and the hand feeling are good, and the rebound resilience is moderate.

Owner:ZHANGZHOU INST OF TECH

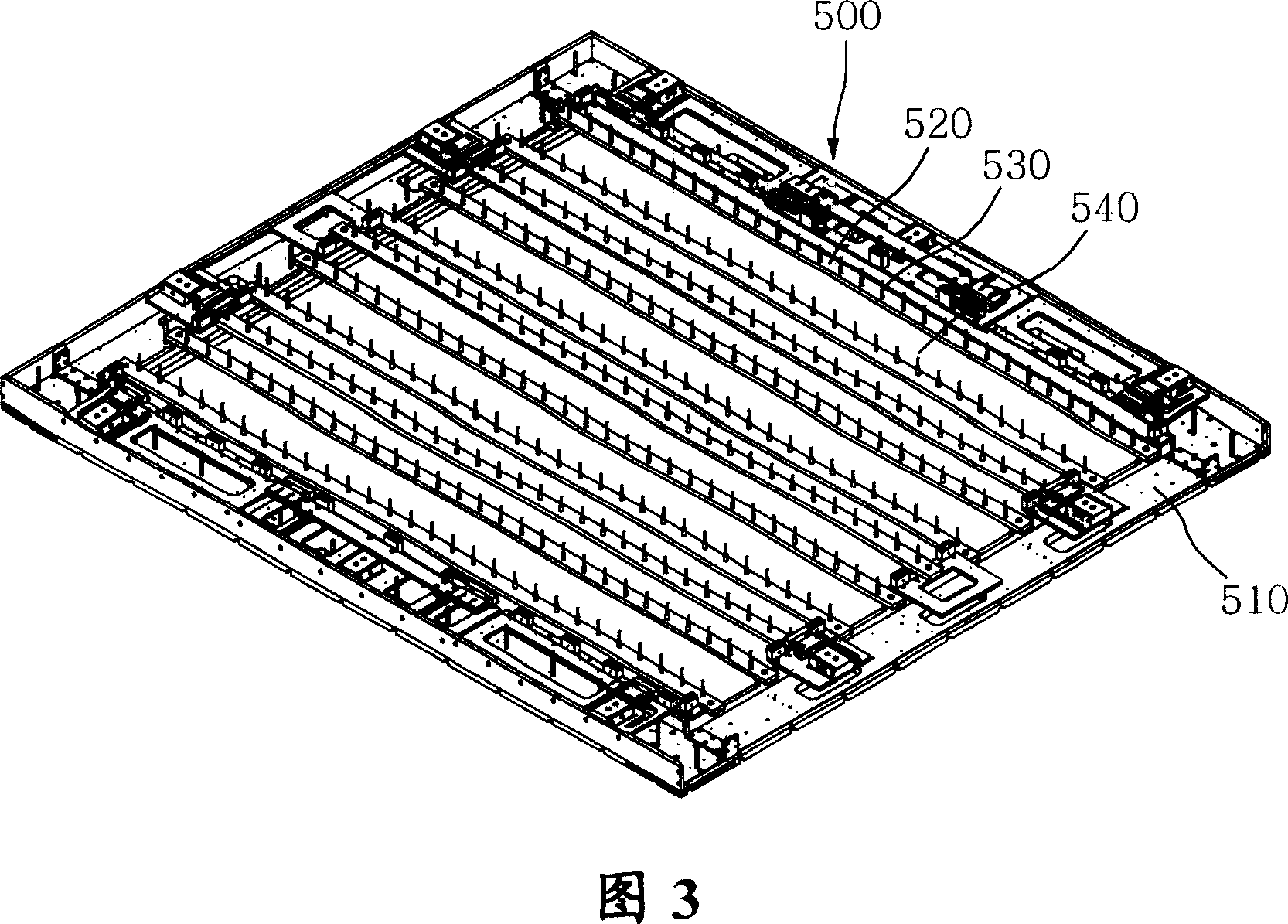

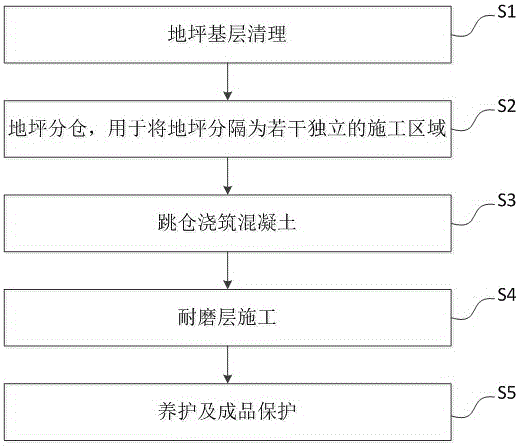

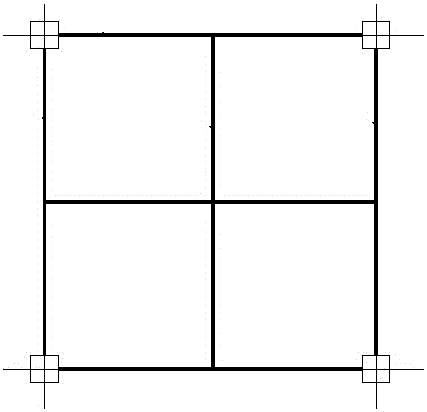

Large-are floor construction method

The invention discloses a large-area floor construction method. The method comprises the steps of floor base course cleaning, floor warehouse division, concrete sequence placement, wear resistant layer construction and maintenance and finished product protection; for the floor warehouse division process, a floor is divided into multiple independent construction areas, concrete ribs divide the floor into multiple independent construction areas, and the floor warehouse division process comprises the following sub-steps of rib making, area dividing, base course drilling, rid fixing, rib horizontal height adjusting, mortar sealing and rib concave groove packing. According to the large-area floor construction method, ribbed concrete sequence placement is adopted, a floor module can be practically and effectively divided according to engineering, the floor surface flatness can be controlled conveniently, cracking and the like, caused by temperature variation or concrete hardening and shrinkage, of the large-area cast-in-place floor can be reduced or avoided, and therefore the construction quality of the wear-resisting floor is practically improved.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

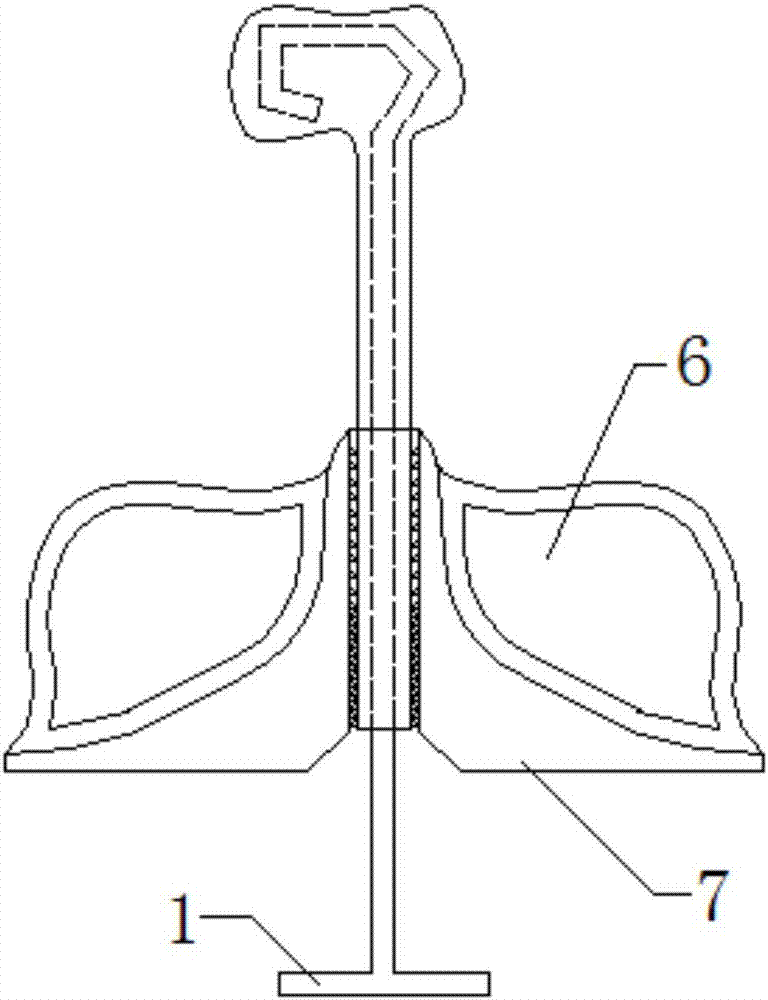

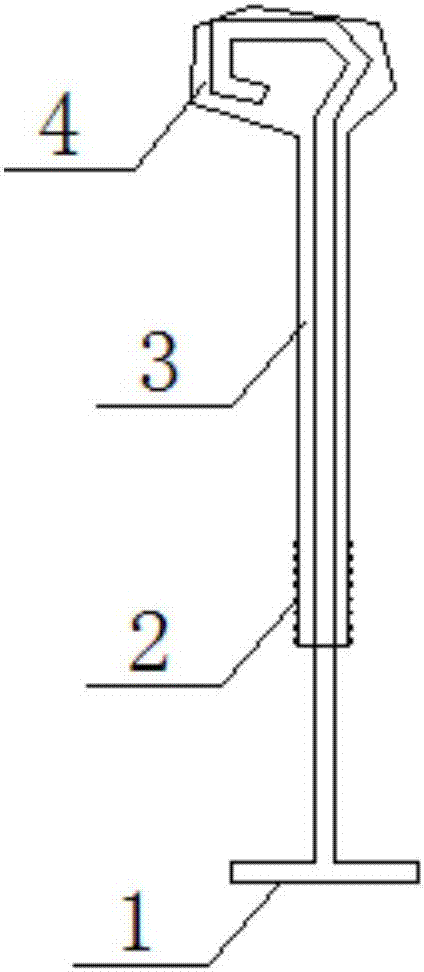

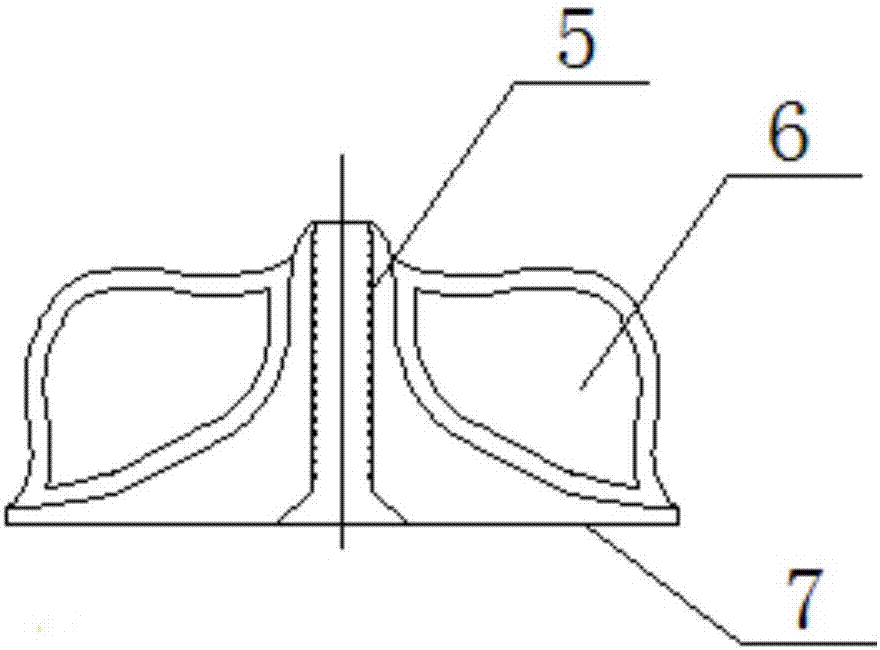

Ceramic tile paving leveling device and ceramic tile paving leveling method

InactiveCN107366421AGuaranteed flatnessImprove work efficiencyBuilding material handlingCeramic tilesMetallurgy

The invention discloses a ceramic tile paving leveling device and a ceramic tile paving leveling method. The device comprises a straight rod and a rotary knob pressure plate, the lower end of the straight rod is provided with a right-angle hook, the rotary knob pressure plate sleeves the straight rod through a thread, and the rotary knob pressure plate is rotated to move up and down along the straight rod. Ceramic tile breakage caused by hammering in a manual leveling process is reduced, simultaneous accurate leveling adjustment of four corners of a ceramic tile is realized, flatness of ceramic tiles after adjustment is guaranteed, operating efficiency is improved, convenience and quickness in operation are achieved, time saving, labor saving, recyclability and cost reduction are realized, and dependency of ceramic tile paving quality on manual proficiency is reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

Matte glaze applied to sanitary ceramics, sanitary ceramics applying matte glaze and preparation method

The invention discloses a matte glaze applied to sanitary ceramics, the sanitary ceramics applying the matte glaze and a preparation method, and relates to the technical field of sanitary ceramics. The matte glaze applied to sanitary ceramics comprises the following raw materials by weight: 25-27 parts of potassium feldspar, 17-20 parts of quartz, 1-3 parts of zinc oxide, 8-12 parts of dolomite, 5-8 parts of wollastonite, 5-8 parts of kaolin, 6-8 parts of aluminum oxide, 7-9 parts of zirconium silicate, 1-4 parts of frit, 6-9 parts of barium carbonate, 5-9 parts of calcined talc and 0.5-1.5 parts of lithium carbonate. A certain quantity of lithium carbonate is introduced to achieve fluxing, the melting temperature of the raw materials is reduced, mutual fusion of the raw materials is facilitated, the viscosity of the frit is improved through lithium carbonate, the viscosity of the matte glaze is reduced, the flowing property of the matte glaze at high temperature is improved, flowing of crystals separated out of the matte glaze is facilitated, the crystals are arranged more uniformly and orderly, the glaze surface flatness is conveniently controlled, and the sanitary ceramic firingefficiency is improved.

Owner:JIANGXI DONGPENG BATHROOM CO LTD +1

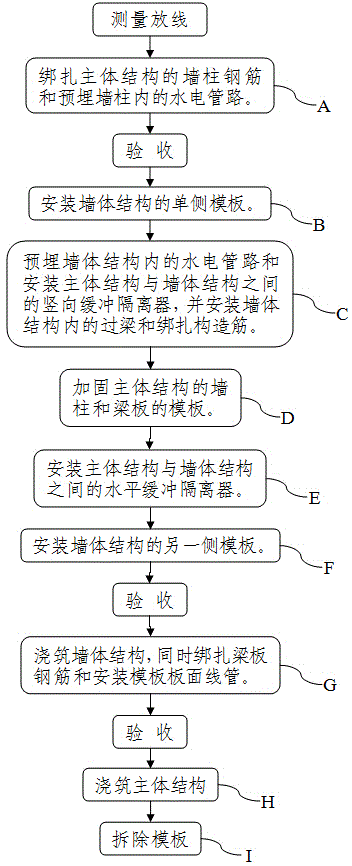

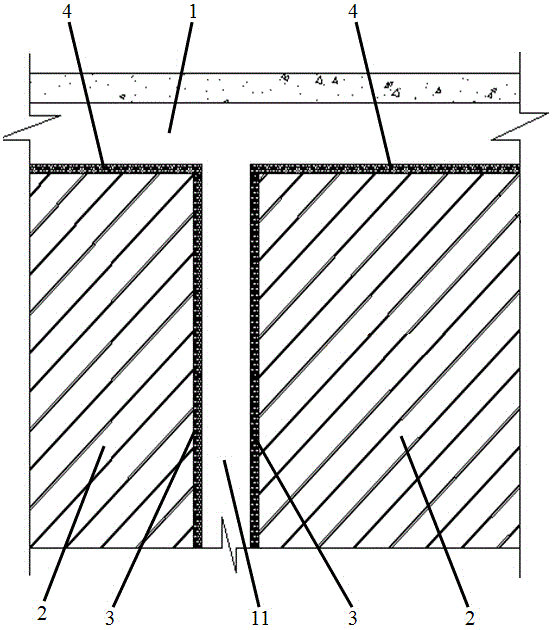

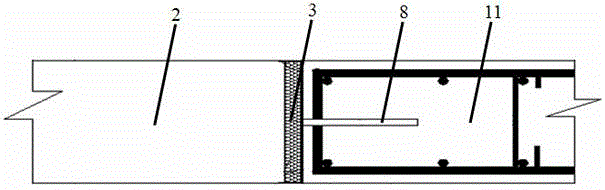

Integral constructing method of house body structure and wall structure and house

The invention relates to an integral constructing method of a house body structure and a wall structure and a house. The method comprises the following steps: (1) binding wall column reinforcing steel bars of the body structure and a hydroelectric pipeline; (2) installing the single-side template of the wall structure; (3) pre-burying the hydroelectric pipeline in the pre-buried wall structure, and installing a vertical buffer isolator between the body structure and the wall structure, and lintels and binding structural bars in the wall structure; (4) reinforcing the wall column of the body structure and the template of a beam plate; (5) installing a horizontal buffer isolator between the body structure and the wall structure; (6) installing the template on the other side of the wall structure; (7) casting the wall structure, binding the beam reinforcing steel bar and installing the template board spool; (8) casting the body structure; (9) removing the template. The body structure and the wall structure are integrally cast, thus the integral constructing method is excellent in formation, simplified in construction, short in construction period, and effectively reduced in construction waste emission; besides hollowing, crack and leakage and other common quality problems caused by plastering are avoided, the wall structure is excellent in overall stability.

Owner:GUANGDONG CONSTAR CONSTR GRP CO LTD

Camera module and circuit board of camera module

InactiveCN105049696AAvoid leaningImprove image qualityTelevision system detailsColor television detailsImaging qualityEngineering

The invention relates to a camera module and a circuit board of the camera module. The circuit board comprises a first circuit board, a reinforcing board and a second circuit board, wherein the first circuit board is provided with an installing surface and a connecting surface which are opposite; the reinforcing board is arranged on the connecting surface; the second circuit board is electrically connected with the first circuit board, and realizes the signal conduction; the installing surface comprises an installing region positioned in the middle part and a peripheral region surrounding the installing region; the installing region is used for installing an image sensing chip of the camera module; a first hollow part hollowing in a direction towards the reinforcing board until the reinforcing board is exposed out is formed in the peripheral region; and through the first hollow part, a lens seat of the camera module can stably stand on a position, corresponding to the first hollow part, of the reinforcing board. The circuit board has the advantages that the lens seat assembled on the circuit board can be effectively prevented from being inclined, so that the camera module has good imaging quality.

Owner:NANCHANG OFILM HUAGUANG TECH CO LTD

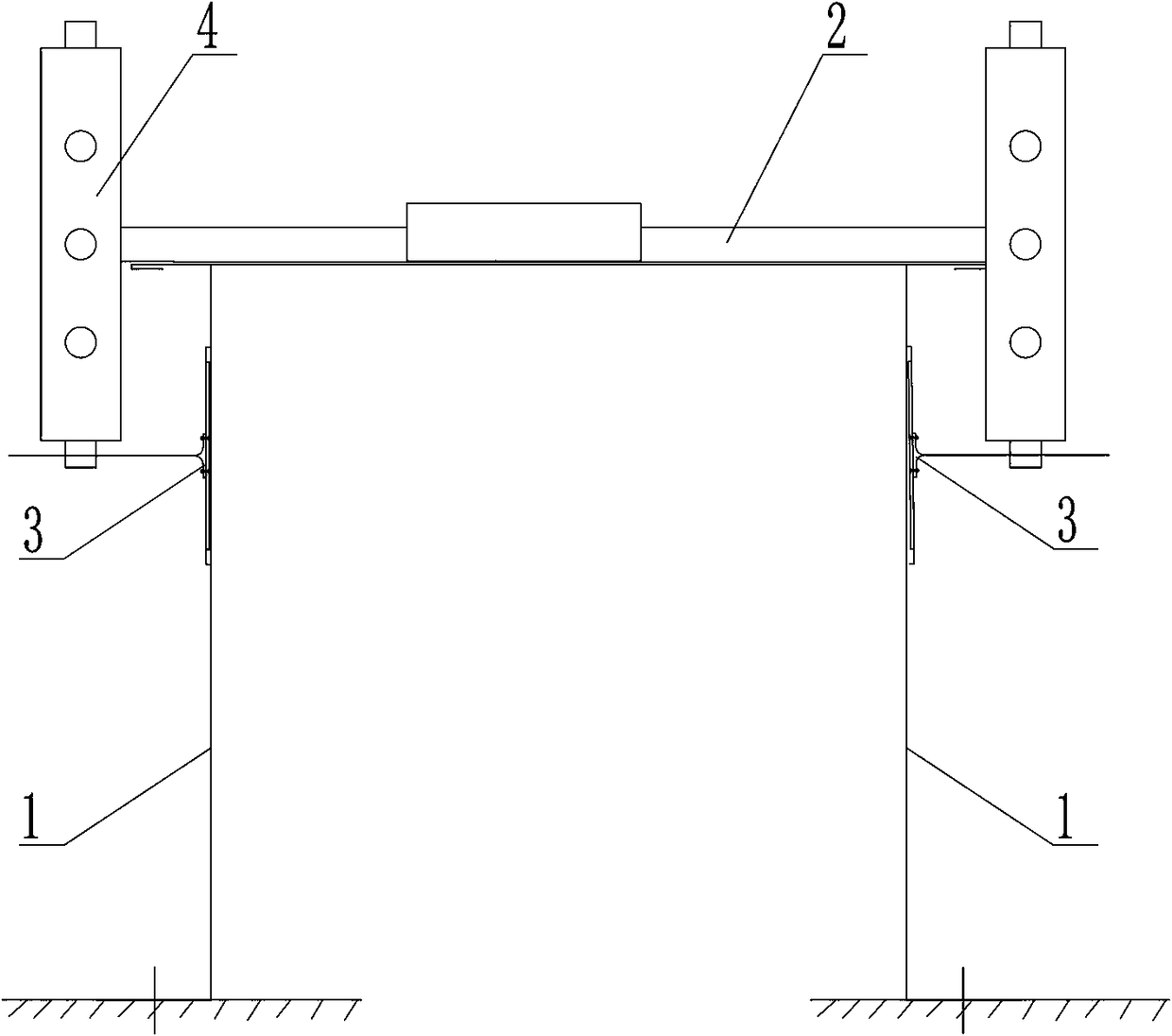

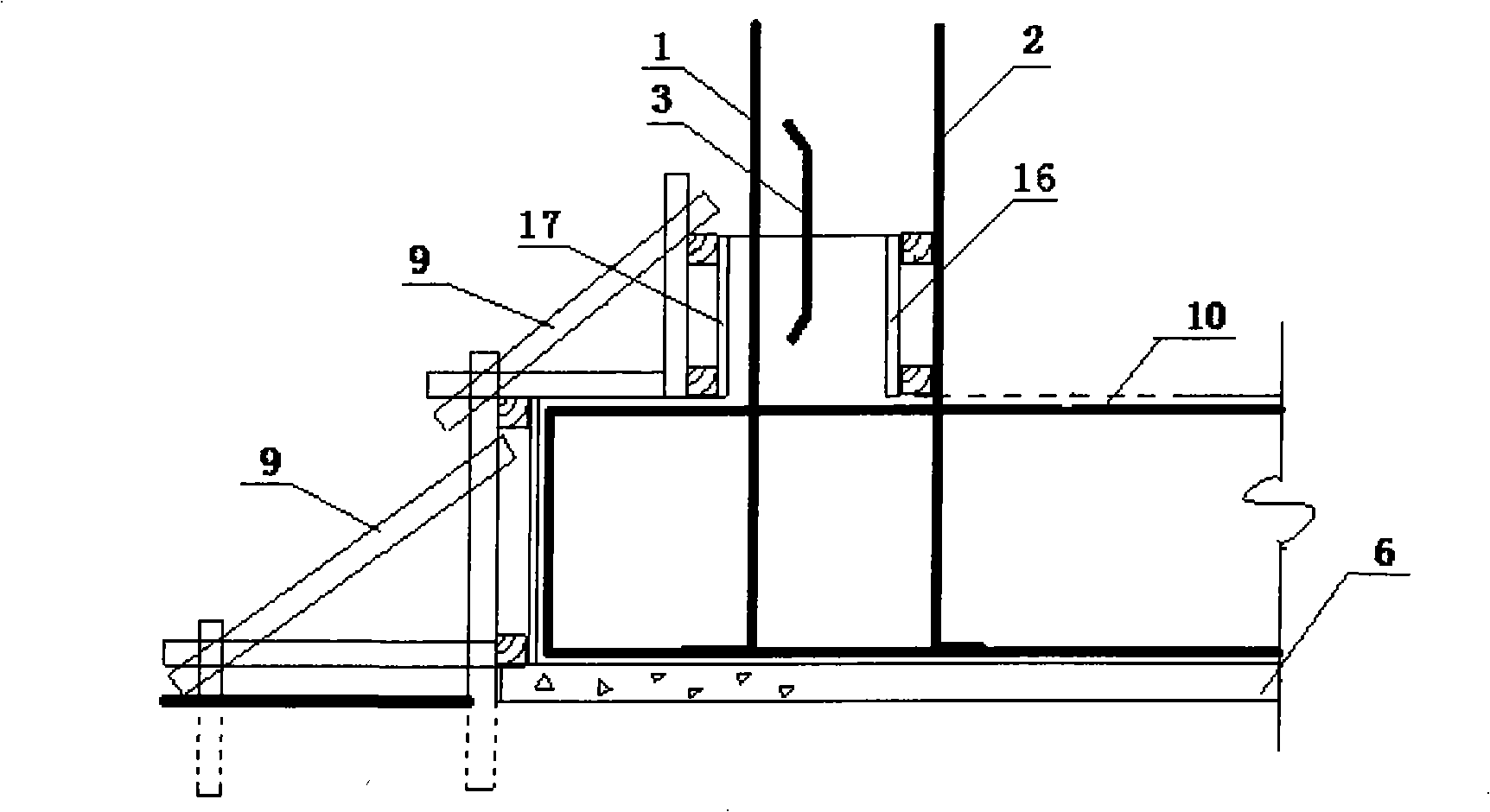

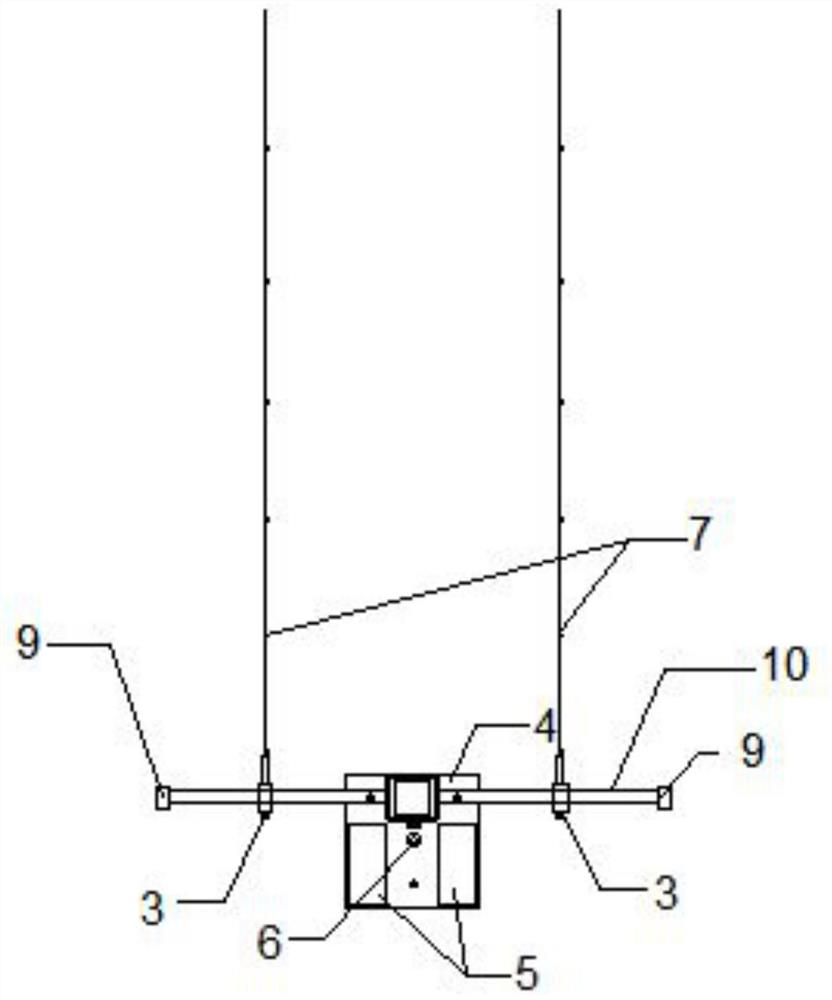

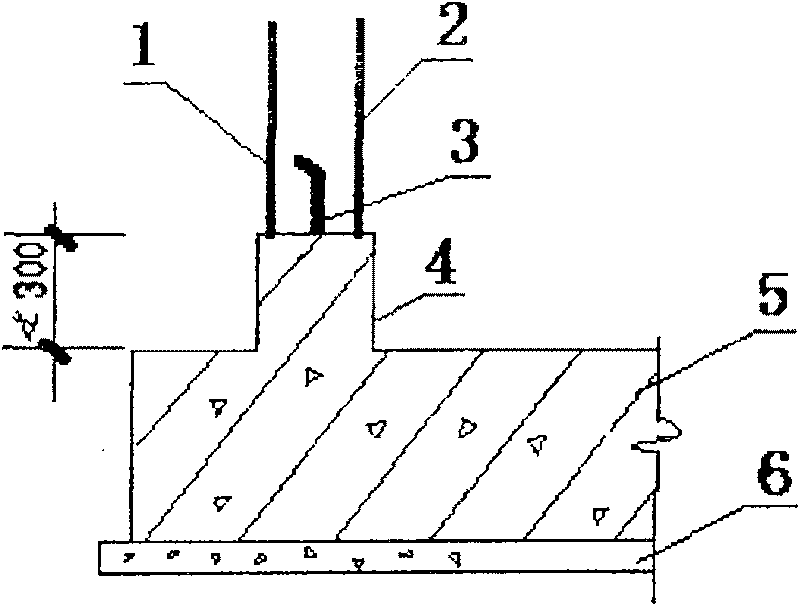

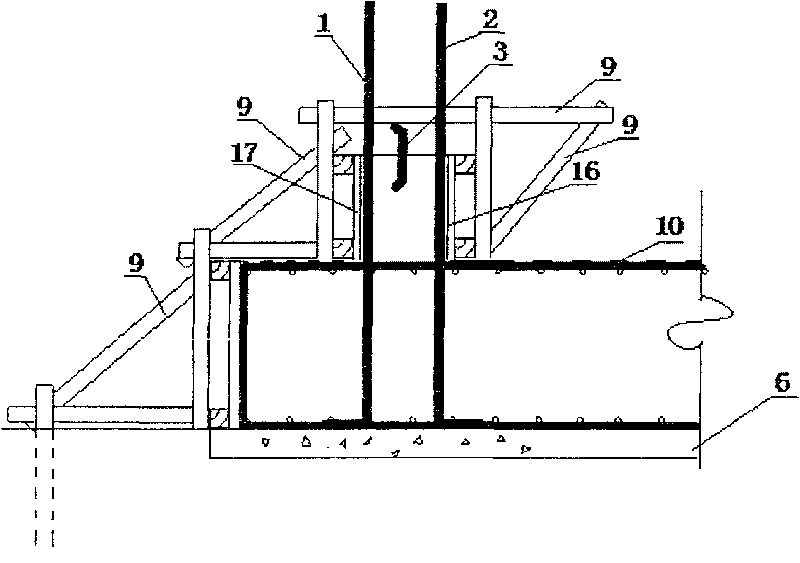

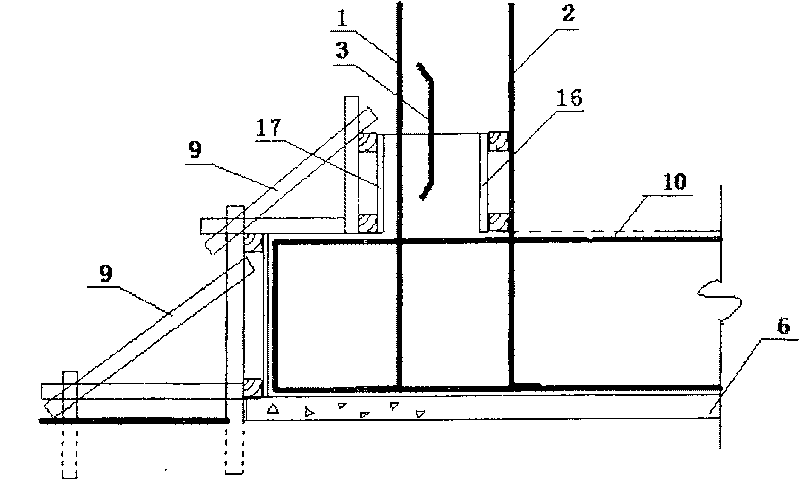

Suspension type pouring-leveling device in building operations and pouring method

The invention provides a suspension type pouring-leveling device in building operations and a pouring method, wherein the suspension type pouring-leveling device comprises a suspension assembly and a leveling assembly. The suspension assembly comprises a fixing device and a connecting bar; a first plane is arranged below the leveling assembly which is located below the connecting bar; the upper portion of the connecting bar is connected with the fixing device; the leveling assembly is hanged on a reserved steel bar by the fixing device, wherein the position of the reserved steel bar is higher than the floor elevation. The suspension type pouring-leveling device controls the flatness and thickness of the whole floor through the arrangement of the leveling assembly. The suspension type pouring-leveling device is easy to install, can be quickly removably after the concrete floor is plastified, and used repeatedly.

Owner:甘肃天力建设工程有限责任公司

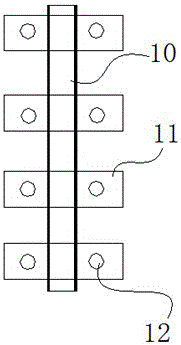

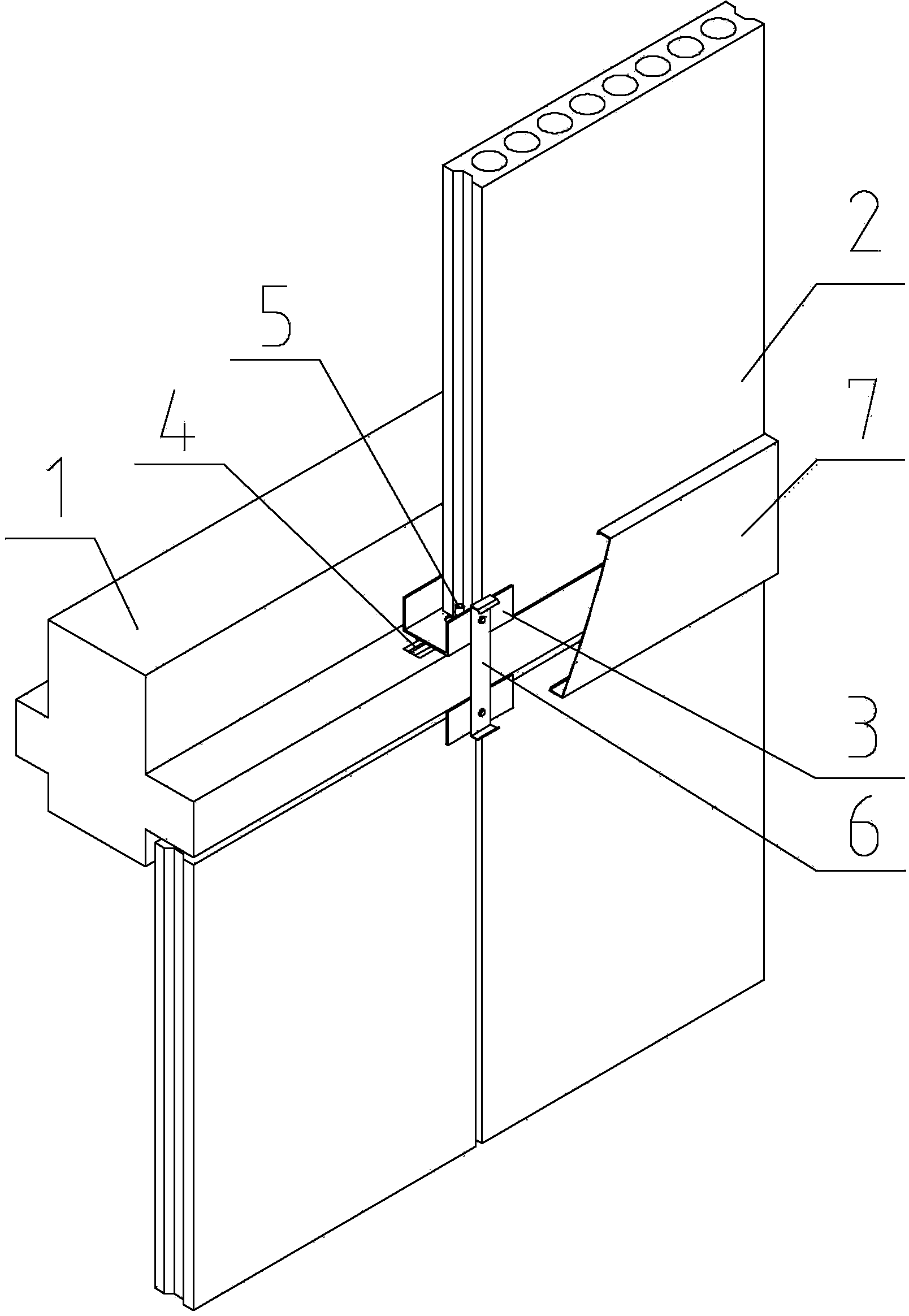

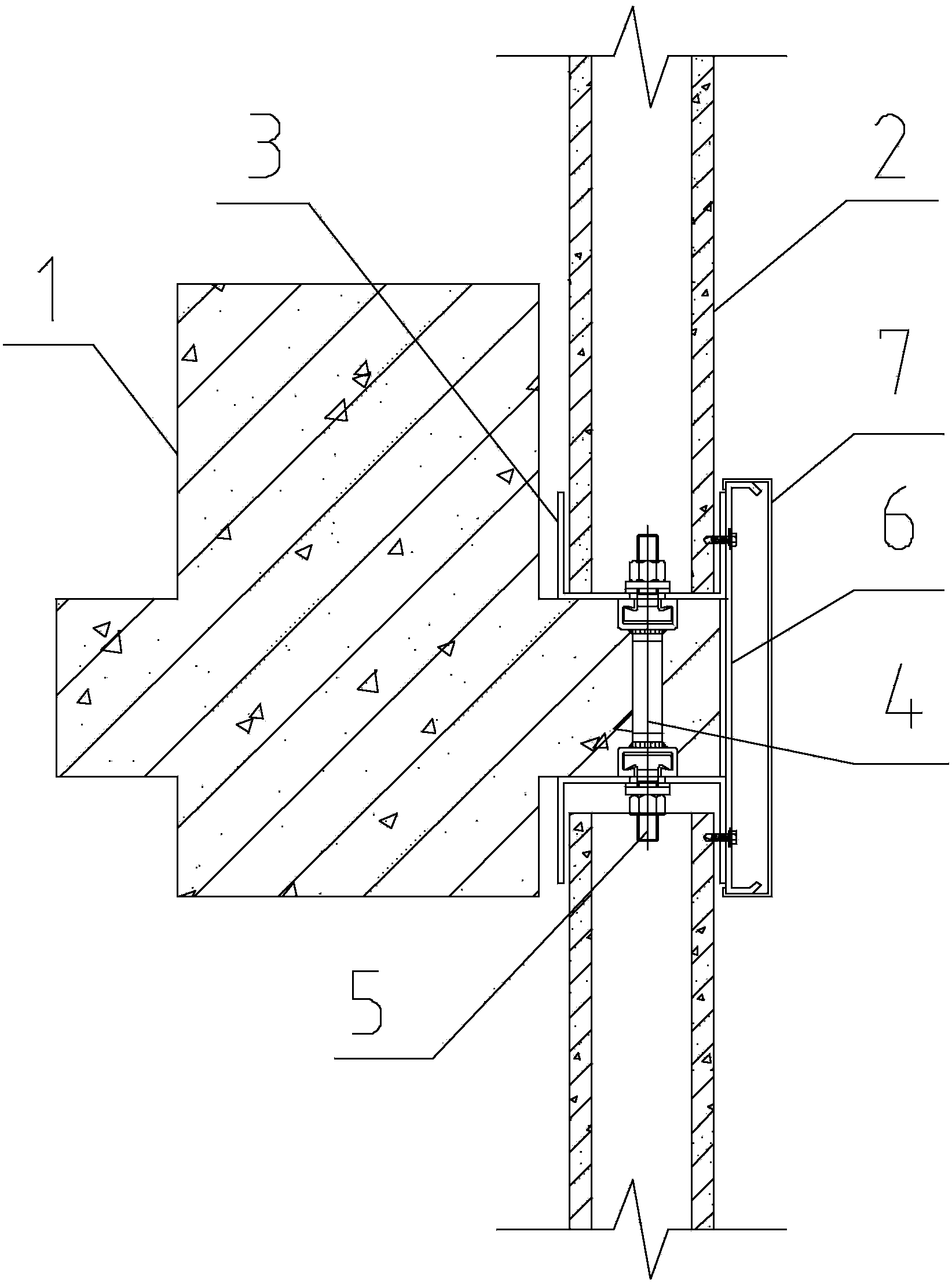

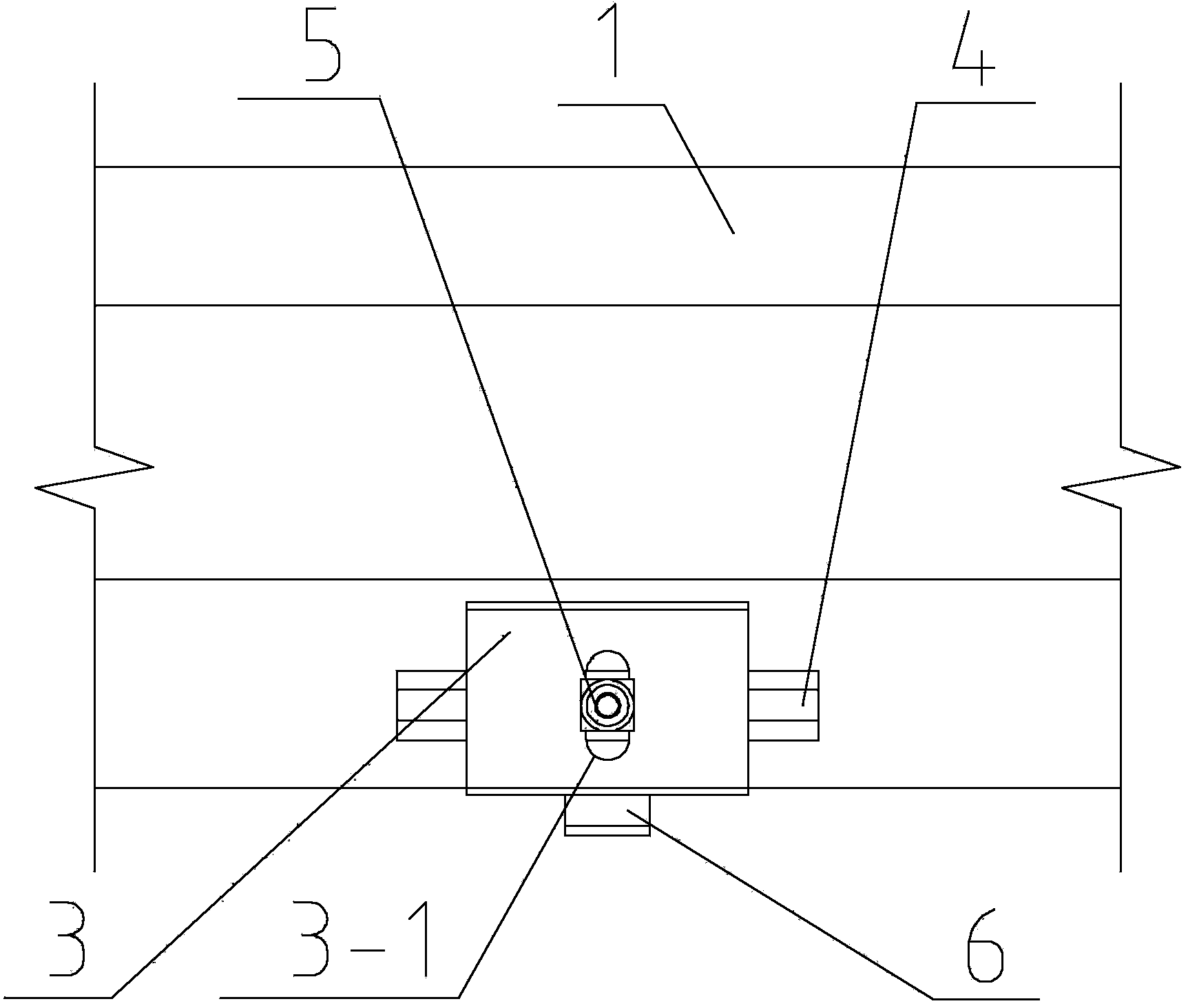

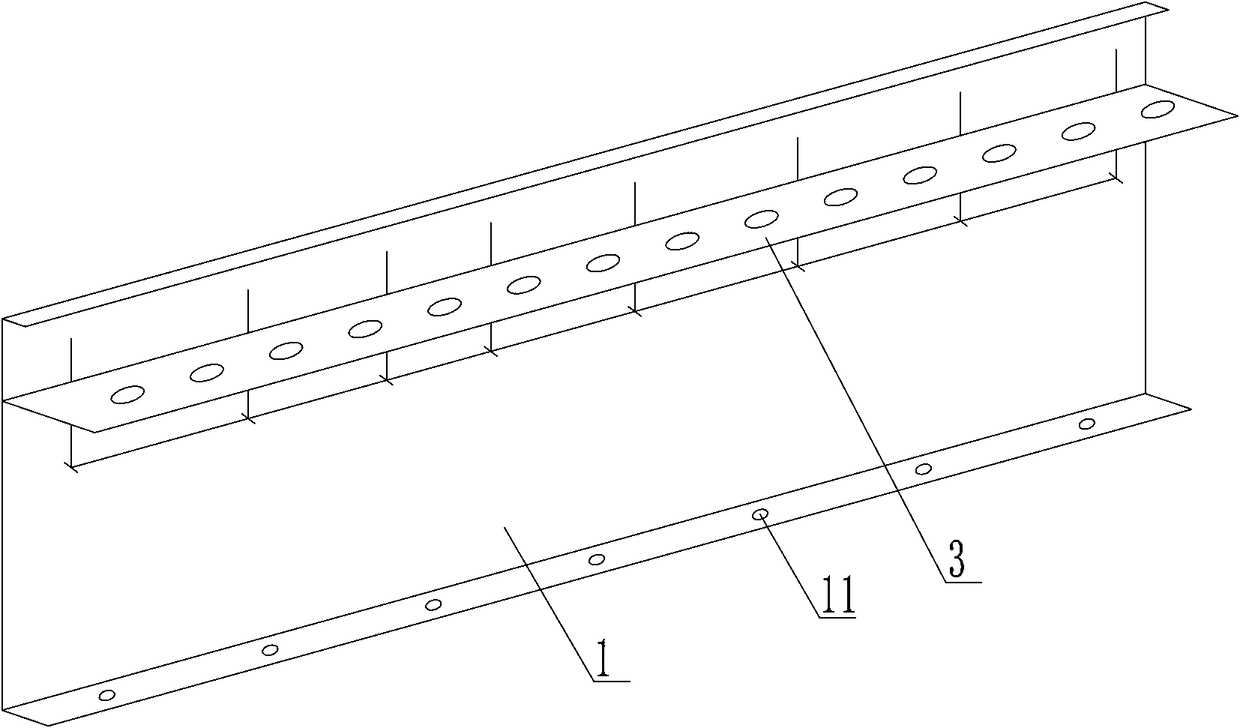

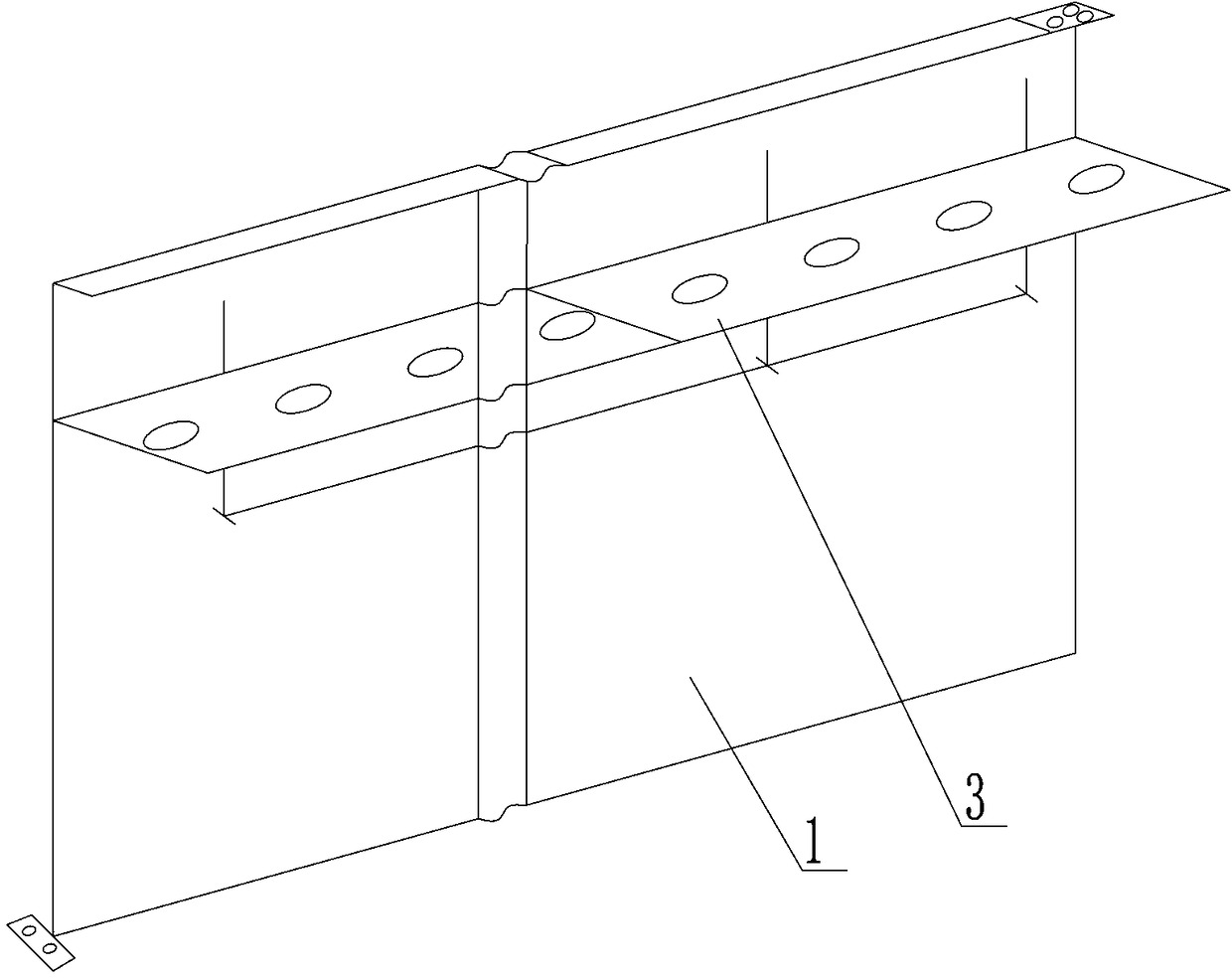

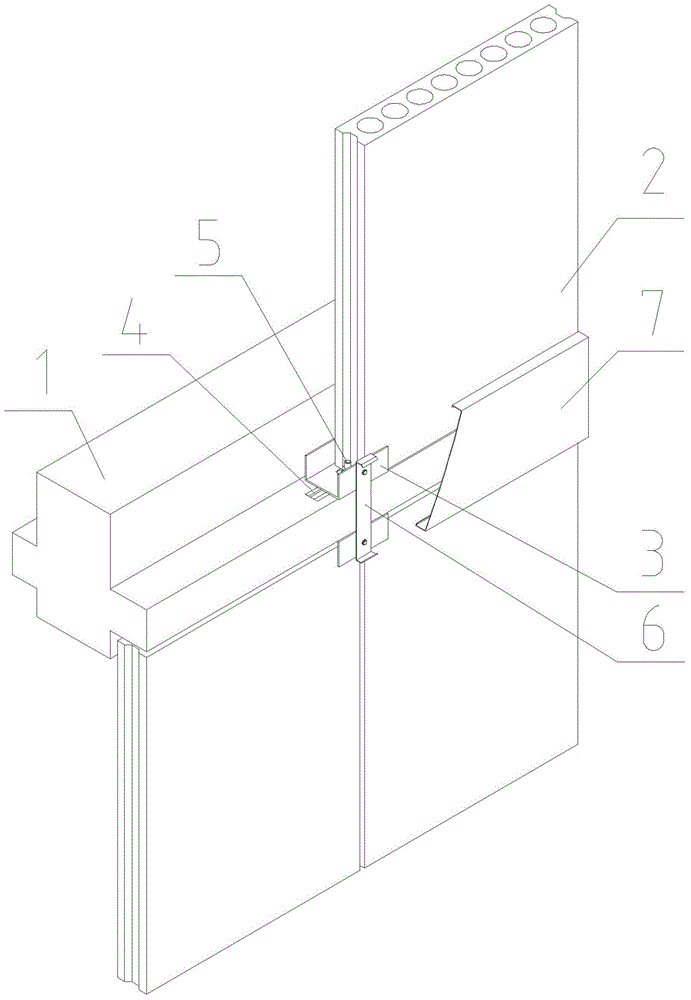

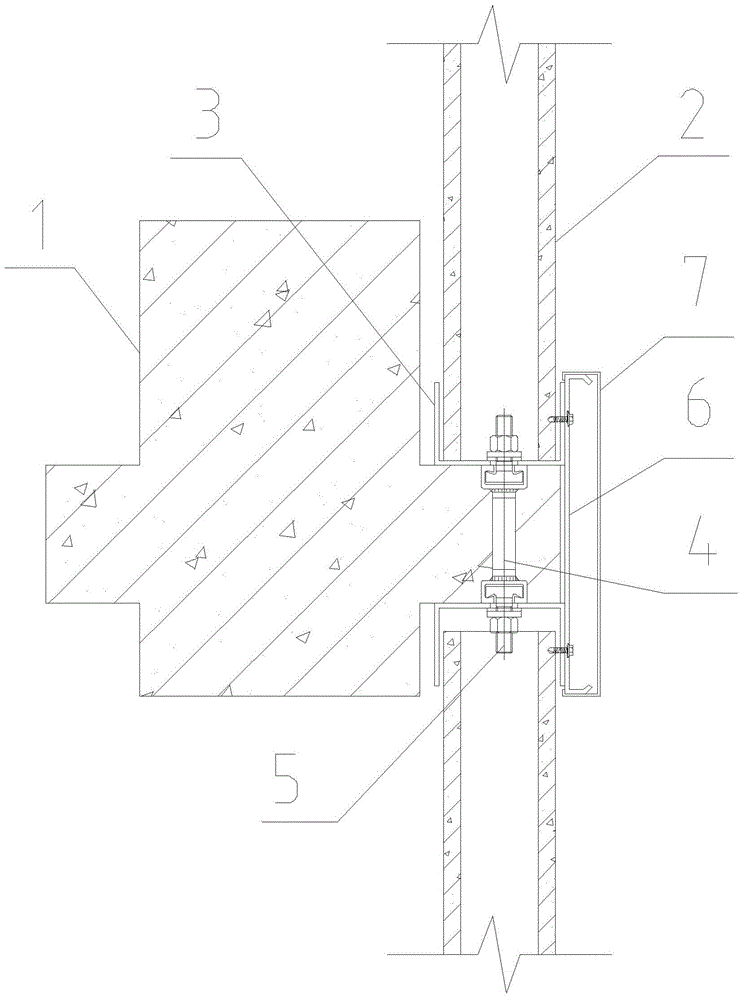

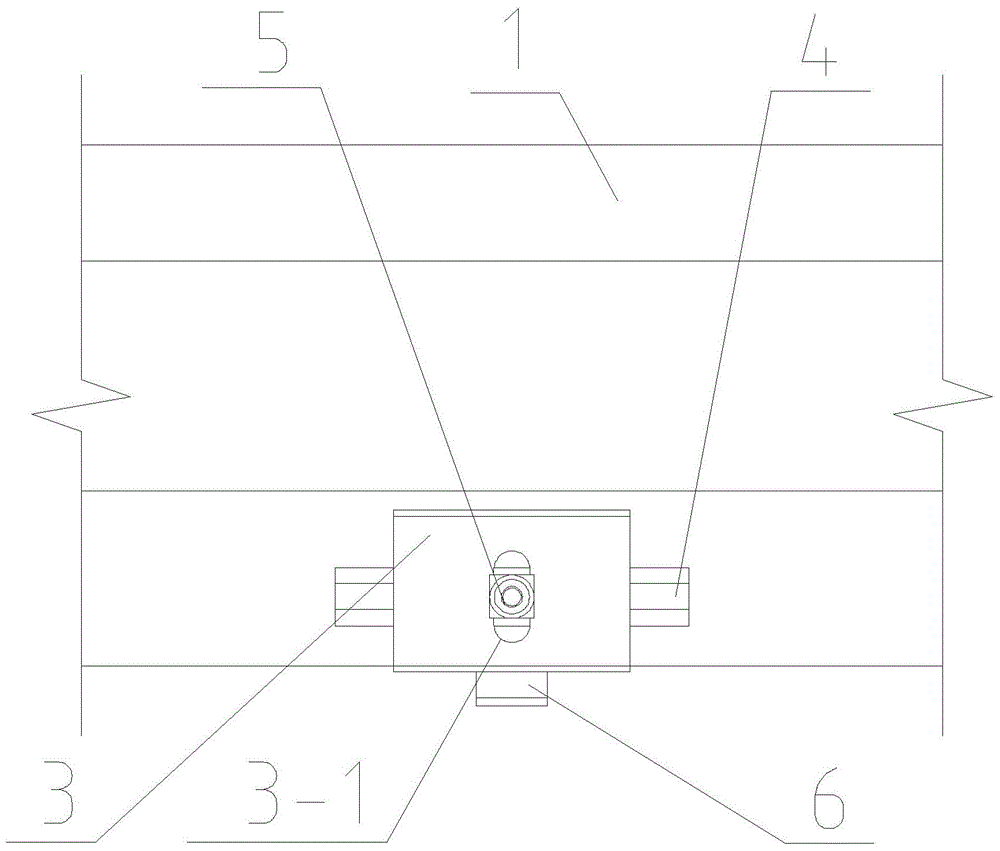

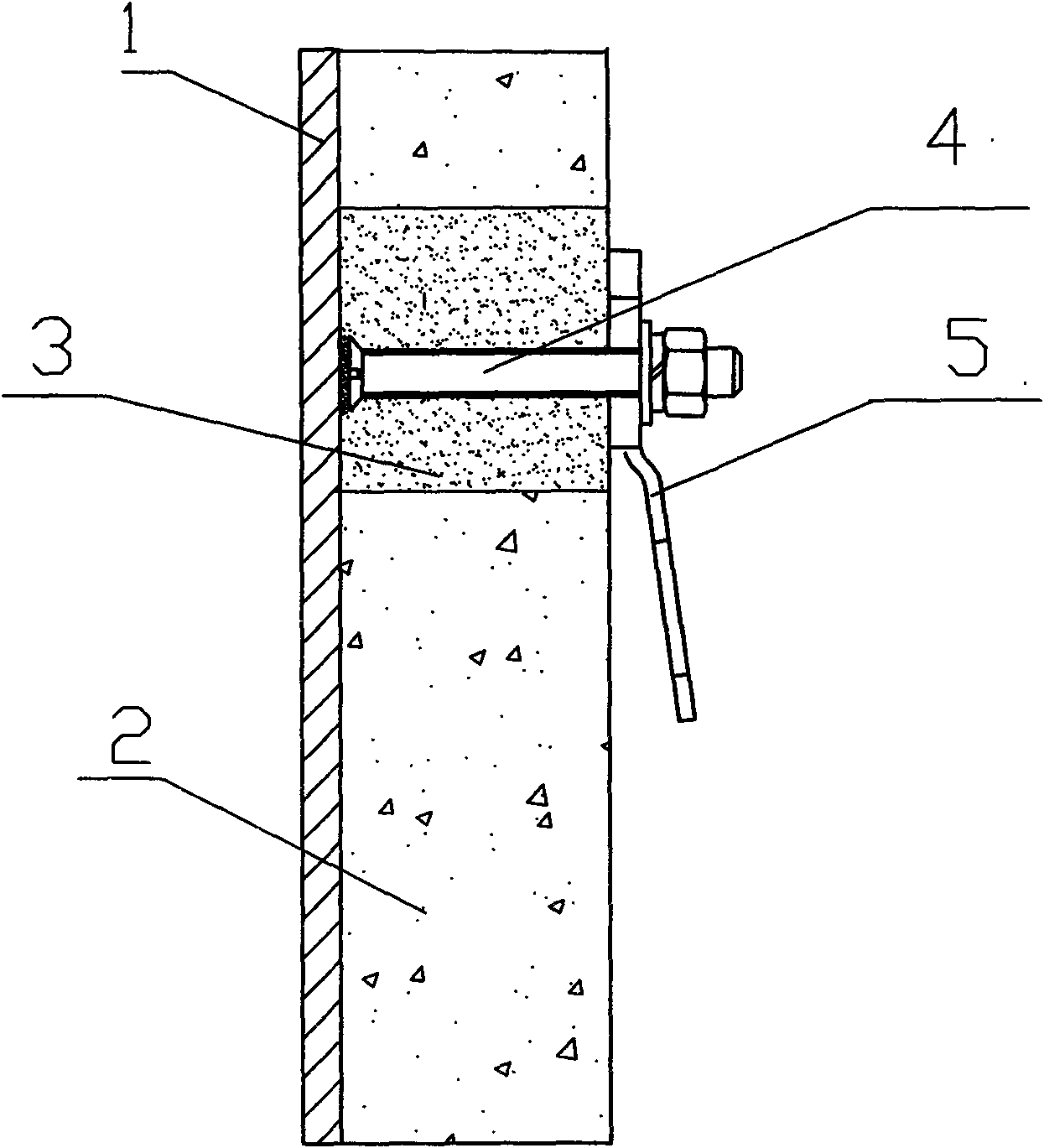

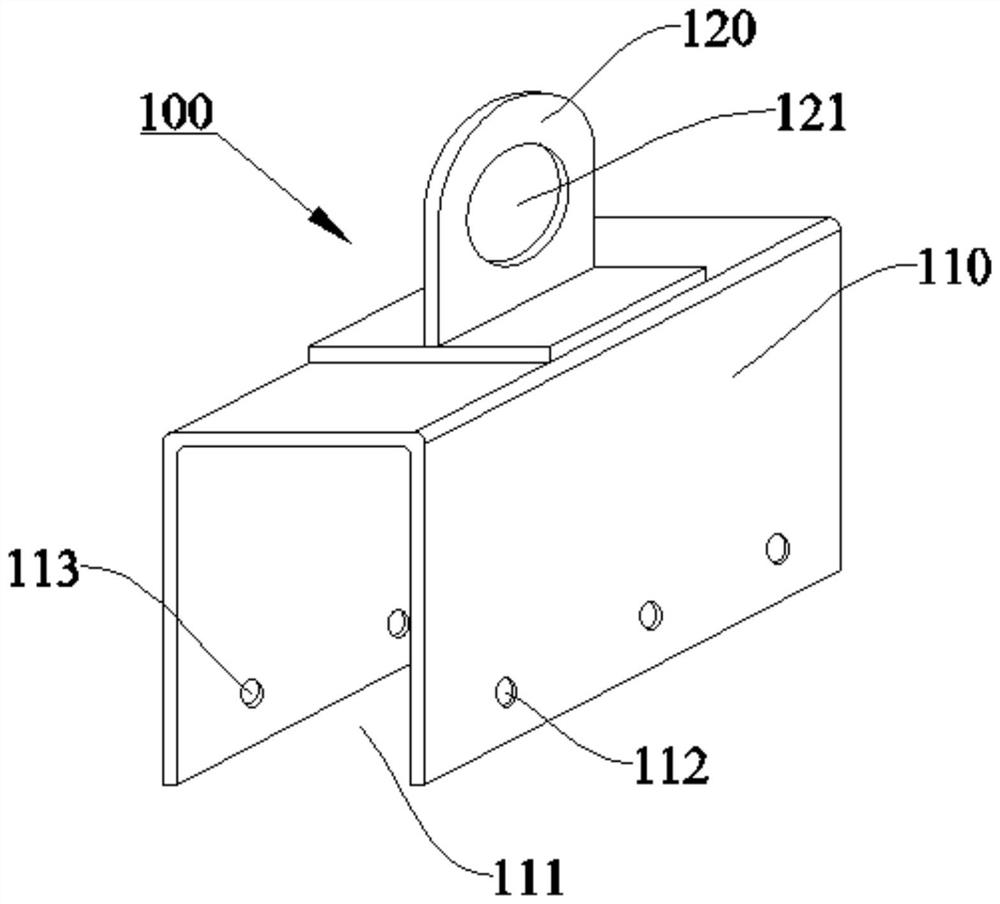

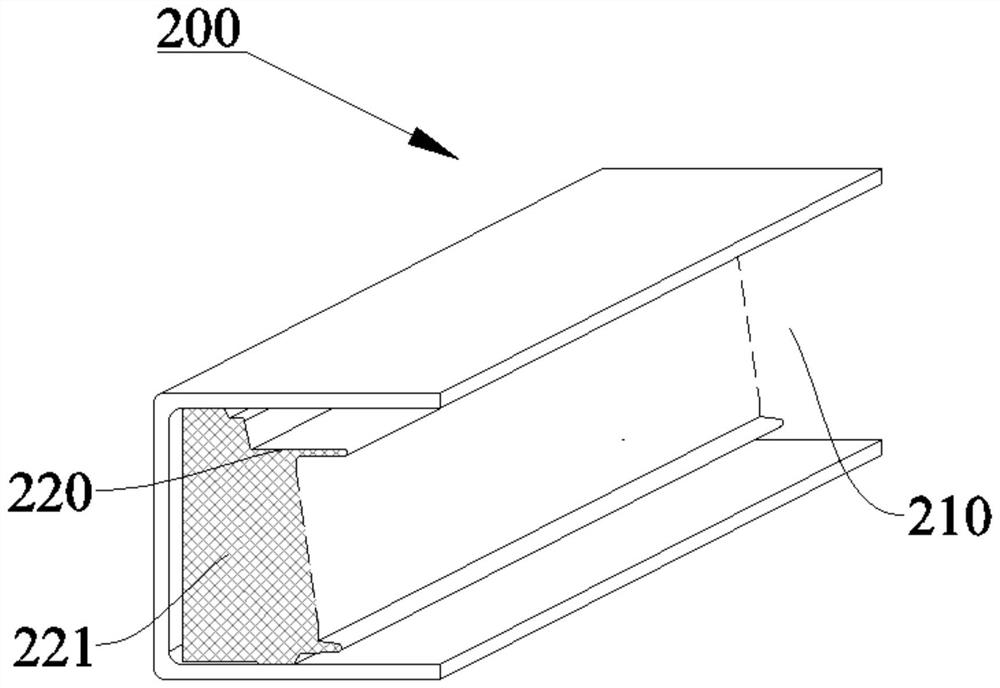

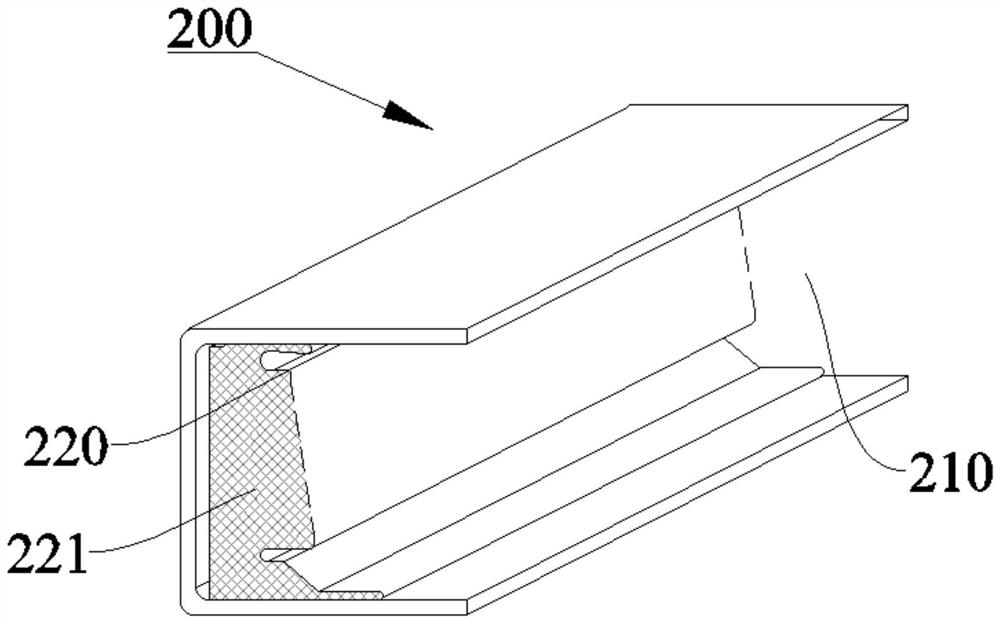

Precise locating mounting connecting structure of assembled wall boards and beam body

InactiveCN103758213AImprove mechanical propertiesReduce the amount of aerial workBuilding constructionsReinforced concreteSteel bar

The invention discloses a precise locating mounting connecting structure of assembled wall boards and a beam body, and belongs to the field of assembled building connecting structures. A pre-buried C-type steel sliding groove component is arranged on a side bearing table of a reinforced concrete precast beam, and two C-type steel sliding grooves of the pre-buried C-type steel sliding groove component are correspondingly exposed on the upper surface and the lower surface of the side bearing table; adjustable locating connecting pieces are groove type steel pieces, and transverse long-strip oval holes perpendicular to the groove edges are formed in the groove bottom faces of the adjustable locating connecting pieces; the two adjustable locating connecting pieces are connected and located with the C-type steel sliding grooves of the pre-buried C-type steel sliding groove component of the reinforced concrete precast beam respectively; due to the fact that the adjustable locating connecting pieces transversely and longitudinally move relative to the C-type steel sliding grooves, transverse and longitudinal moving adjustment and locating of the adjustable locating connecting pieces on the upper surface and the lower surface of the bearing table of the reinforced concrete precast beam can be achieved, prefabricated wall boards are correspondingly embedded into grooves in two ends of the upper adjustable locating connecting piece and the lower adjustable locating connecting piece respectively, and rapid locating and mounting of the assembled building wall boards in the prefabricated beam can be achieved.

Owner:HUBEI HONGYI STEEL CONSTR ENG

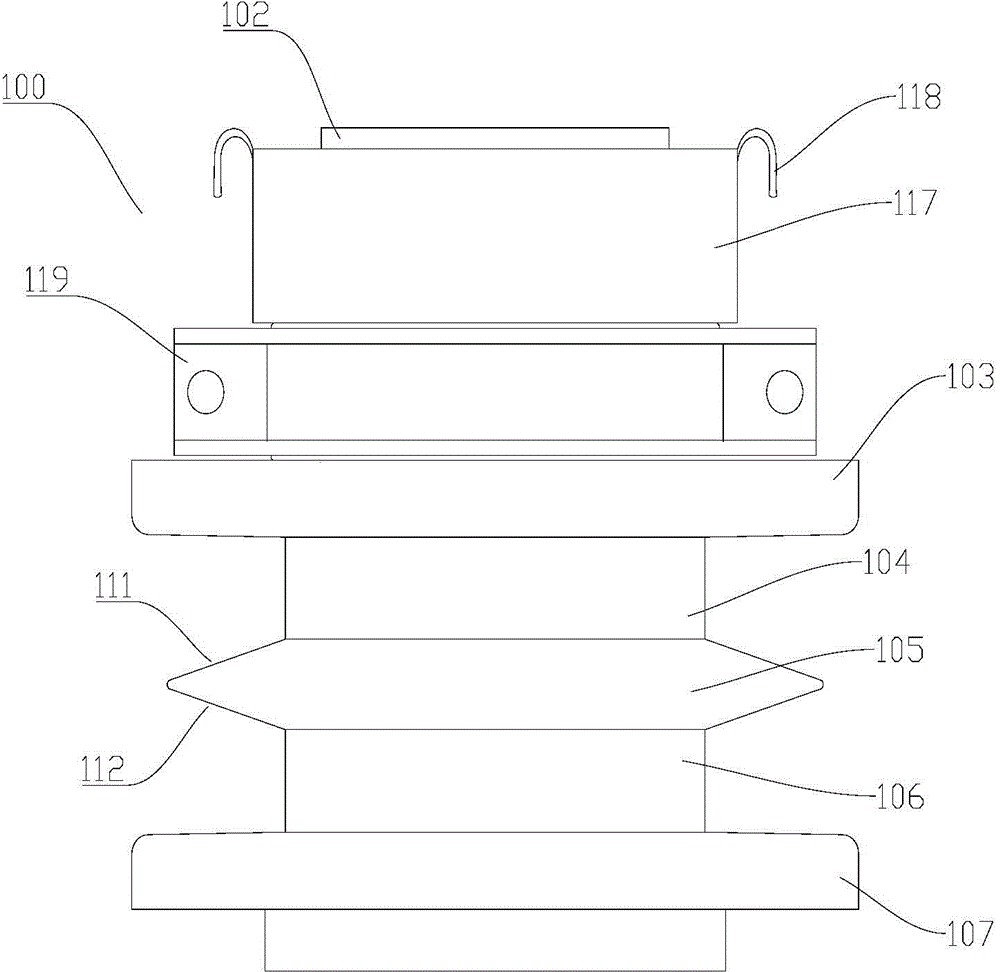

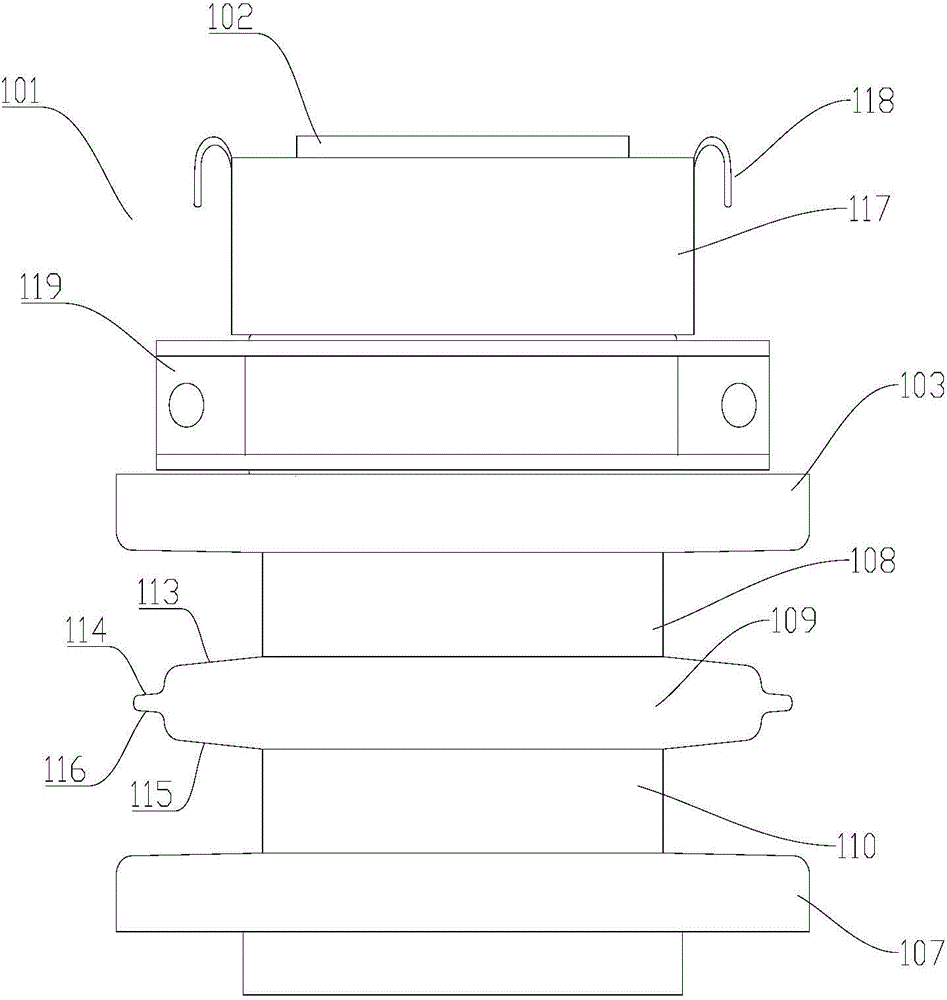

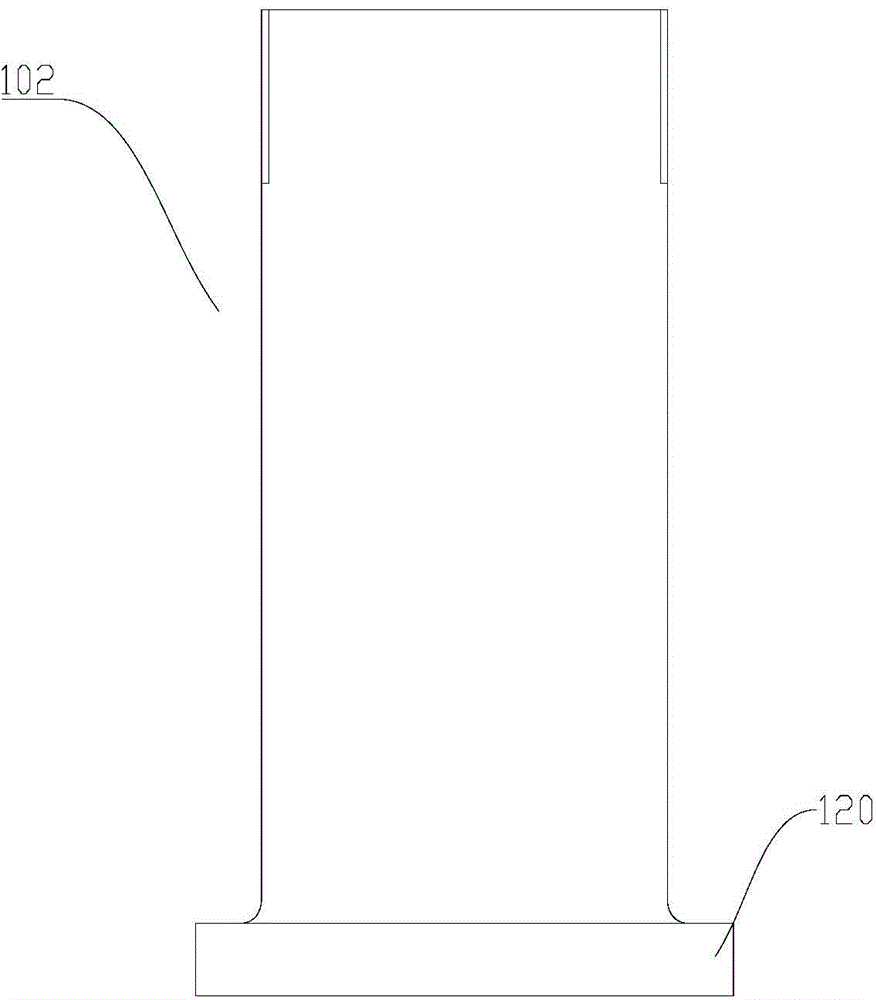

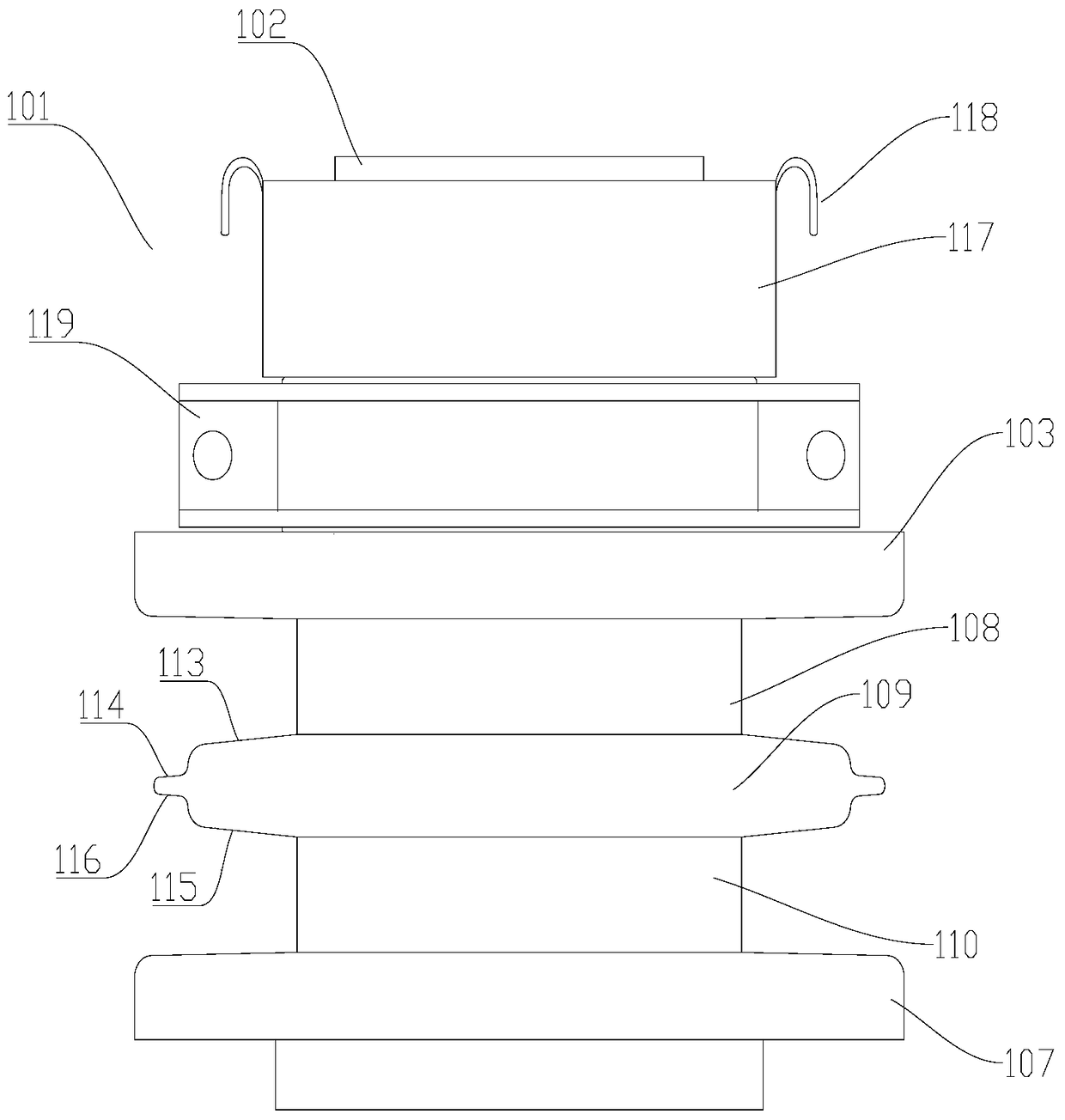

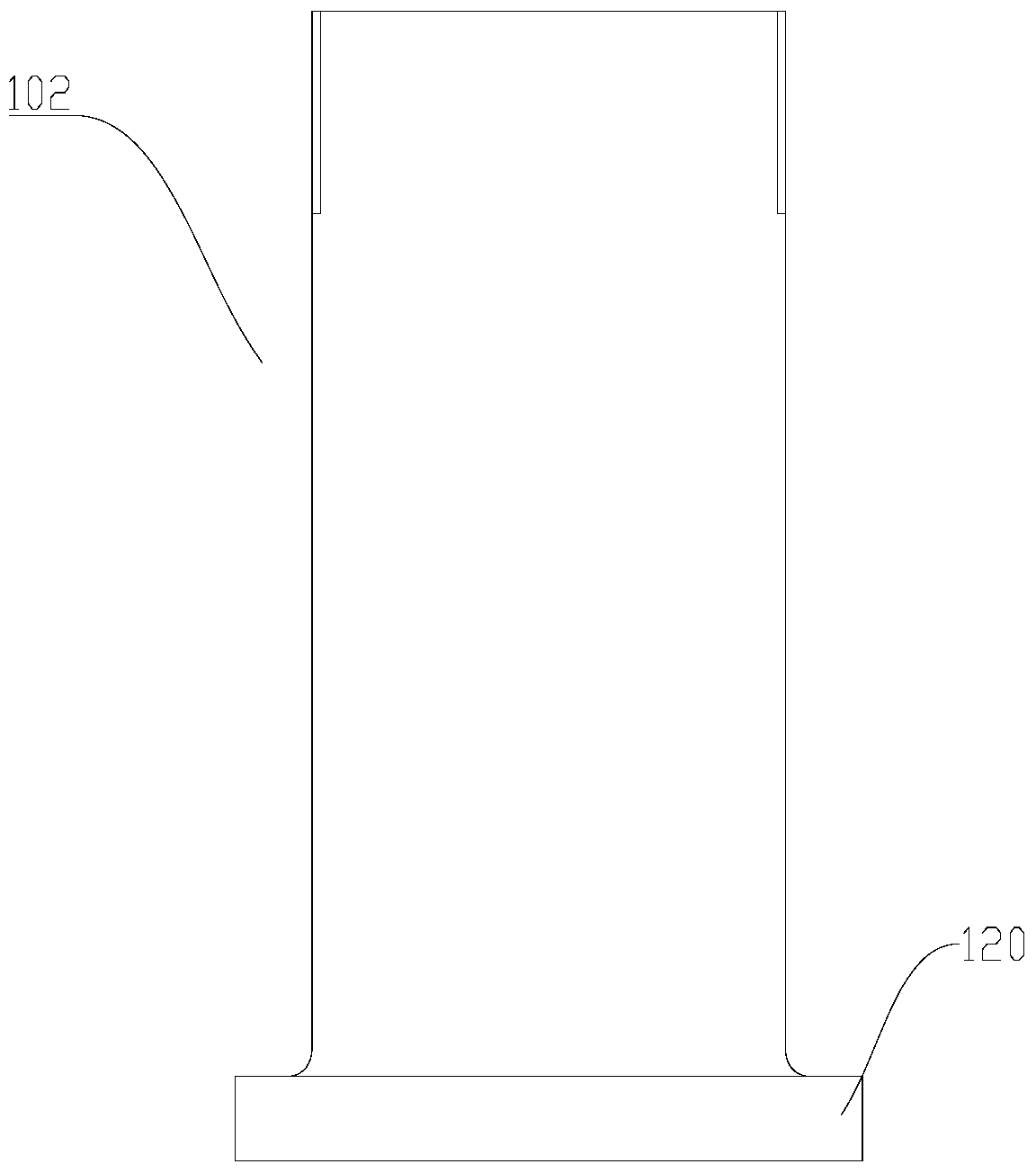

Assembling die and flanging manufacturing process

ActiveCN104801639AHigh dimensional accuracyFlatness is easy to controlMetal rollingManufacturing technologyFlanging

The invention relates to the technical field of wind power flange manufacturing, in particular to an assembling die and a flanging manufacturing process. The assembling die comprises a preforming die and a forming die, wherein the preforming die is used for performing radial preforming rolling on the inner wall of an annular flange blank by adopting a semi-closure hole pattern; the forming die is used for performing radial forming rolling on the inner wall of the annular flange blank by adopting the semi-closure hole pattern; the preforming die comprises a quick-changing barrel; an upper baffle, an upper pre-die, a pre-cutting knife, a lower pre-die and a lower baffle sleeve the quick-changing barrel from top to bottom in sequence; the forming die comprises the quick-changing barrel; the upper baffle, an upper main die, a main cutting knife, a lower main die and a lower baffle sleeve the quick-changing barrel from top to bottom in sequence. The assembling die and the flanging manufacturing process disclosed by the invention, dimensional accuracy of rolling and ring rolling is increased, the flatness of the end face of a product can be conveniently controlled, and is increased; the product material and cost are reduced, and manufacturing is time-saving and labor-saving; the energy consumption of the process is low, the production efficiency is high, and the product quality is improved.

Owner:SHANXI DOUBLE RING HEAVY MACHINERY CO LTD

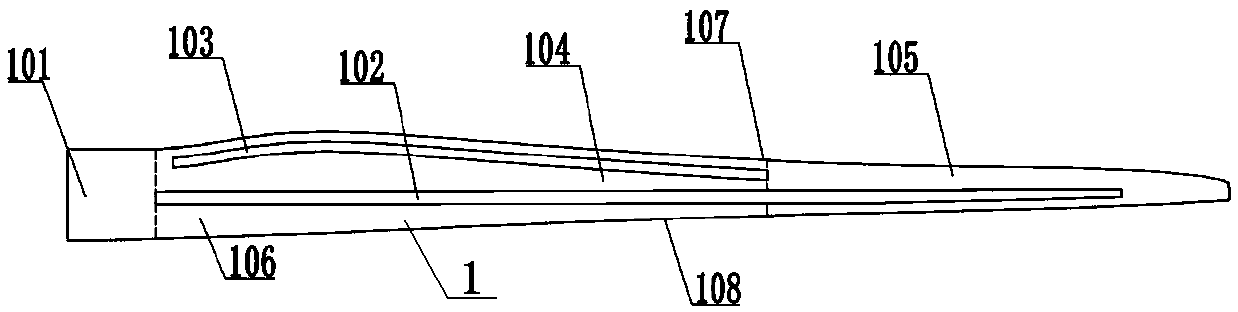

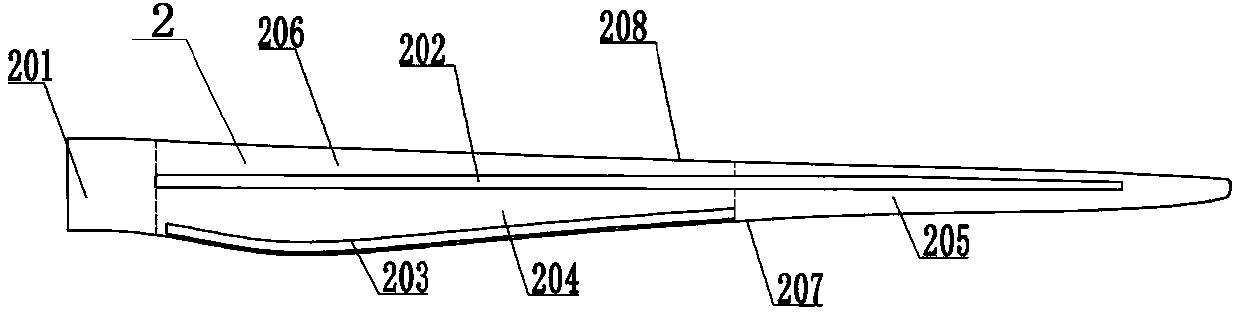

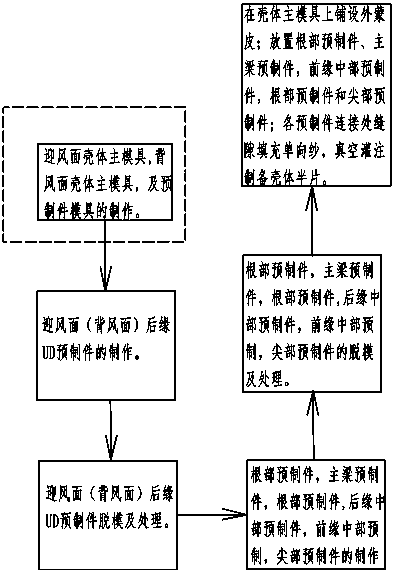

Wind power blade manufacturing method

The invention discloses a wind power blade manufacturing method, and relates to the technical fields of large wind power blade design and manufacture. The wind power blade manufacturing method comprises the steps that all shell laying materials except skin are prefabricated in a regional mode, then outer skin is laid on a shell main mold, a shell prefabricated member is arranged, inner skin is laid, a flow guiding auxiliary material and a vacuum bag film are laid to build a vacuum system, overall pouring is conducted, and then the shell technology defects are greatly reduced. The wind power blade manufacturing method has the beneficial effects that the shell laying quality is improved, the shell pouring difficulty is reduced, the technology defects such as laying wrinkles and bad pouring of a shell structure are reduced, the probability that shell half piece scrap is caused by the local defects of blades is decreased, and the mold occupation time of local blade maintenance is shortened.

Owner:LUOYANG SUNRUI WIND TURBINE BLADE

Slope concrete pouring self-elevating formwork

PendingCN109339071AHeight adjustableSimple structureCoastlines protectionExcavationsStructural engineeringUltimate tensile strength

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD

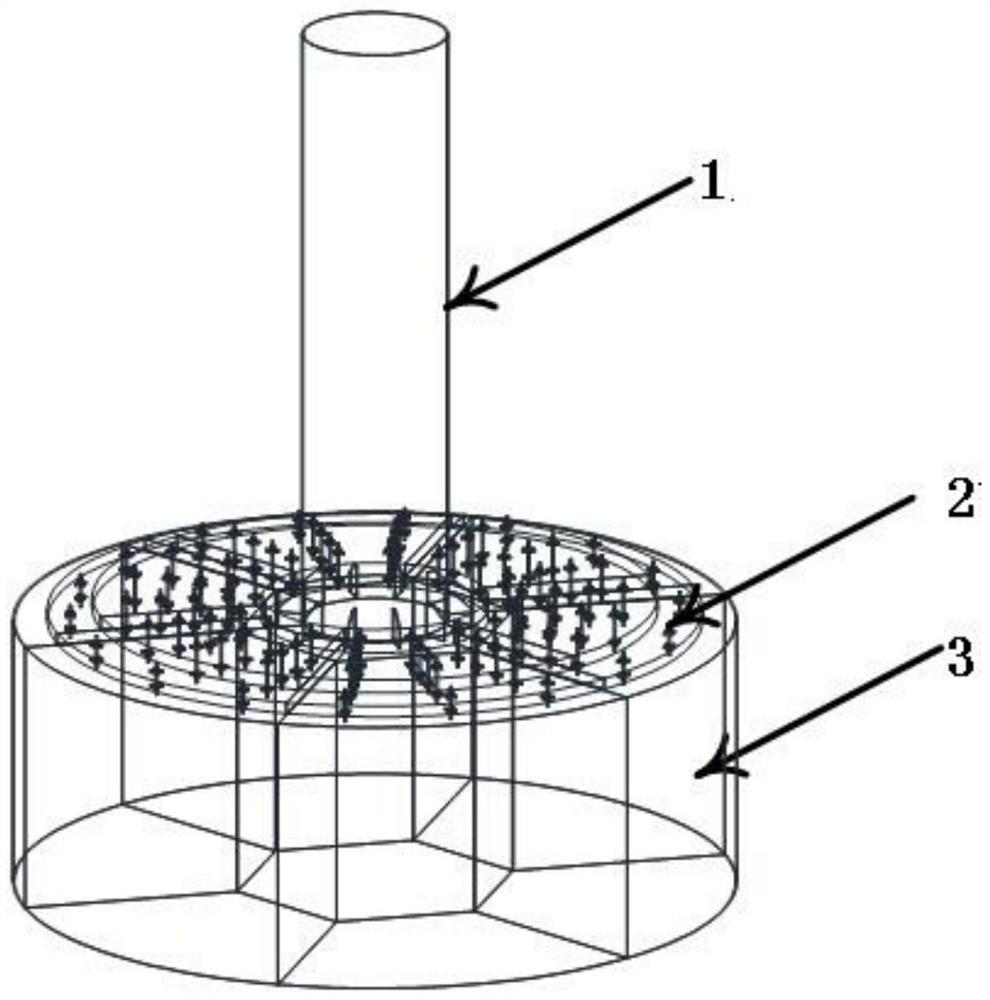

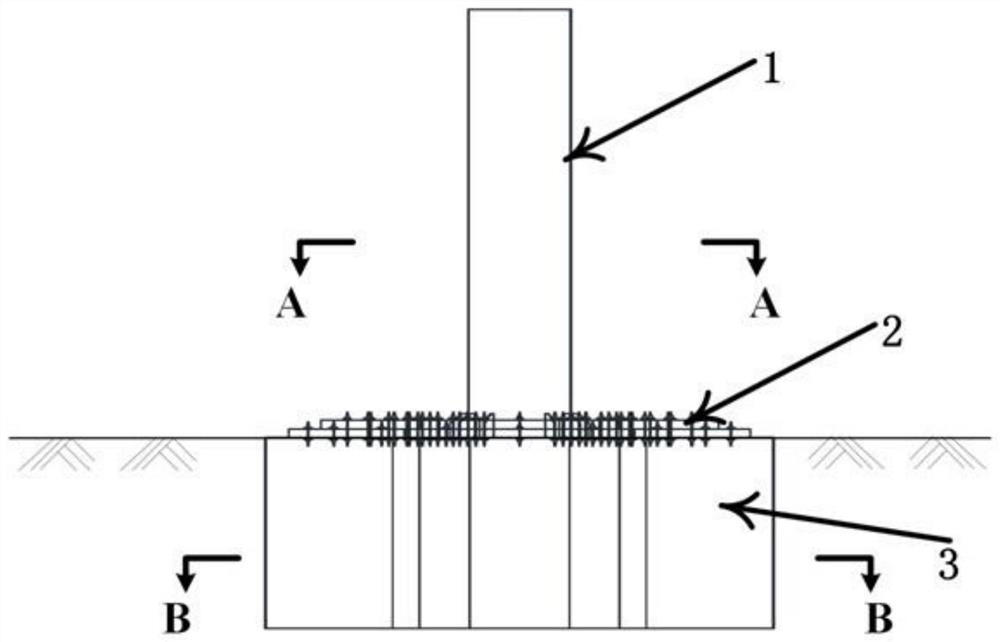

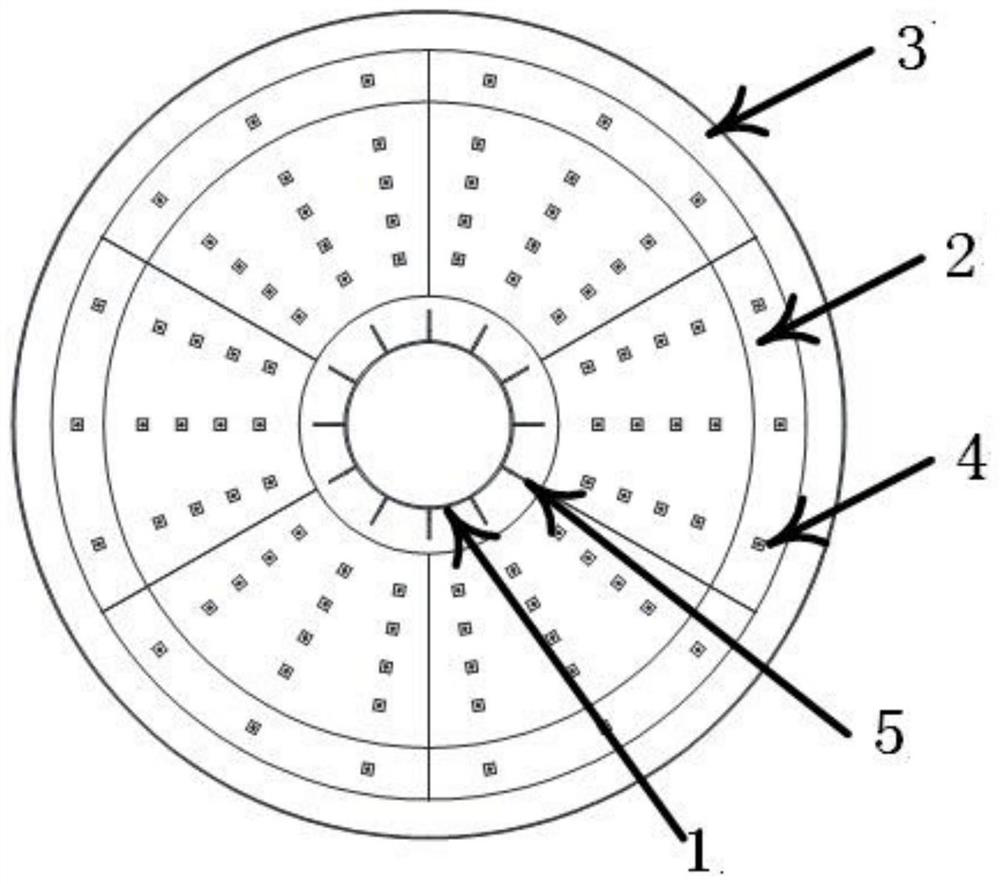

Suction bucket foundation with prefabricated concrete pressing blocks

PendingCN112012238AWeight increaseSolve the technical problems of long time consumption, long maintenance time and large space occupationBulkheads/pilesSuction forceArchitectural engineering

The invention discloses a suction bucket foundation with prefabricated concrete pressing blocks. The suction bucket foundation comprises an upper transition section and a lower suction bucket, the upper transition section is arranged on the upper portion of the lower suction bucket, and the multiple prefabricated concrete pressing blocks are arranged on the lower suction bucket. According to the suction bucket foundation, the problems that in order to increase the weight of the upper transition section in an existing suction bucket foundation, the overall weight of the suction bucket foundation is increased by directly pouring and tamping concrete on the lower bucket body, however, concrete is poured on the surface of the bucket body for a long time, the maintenance time is long, the occupied area is large, meanwhile, the overall flexural rigidity of an existing suction bucket foundation structure needs to be improved by increasing the height of the bucket body, and the structural steel consumption is large can be effectively solved.

Owner:HUANENG YANCHENG DAFENG NEW ENERGY POWER GENERATION CO LTD +3

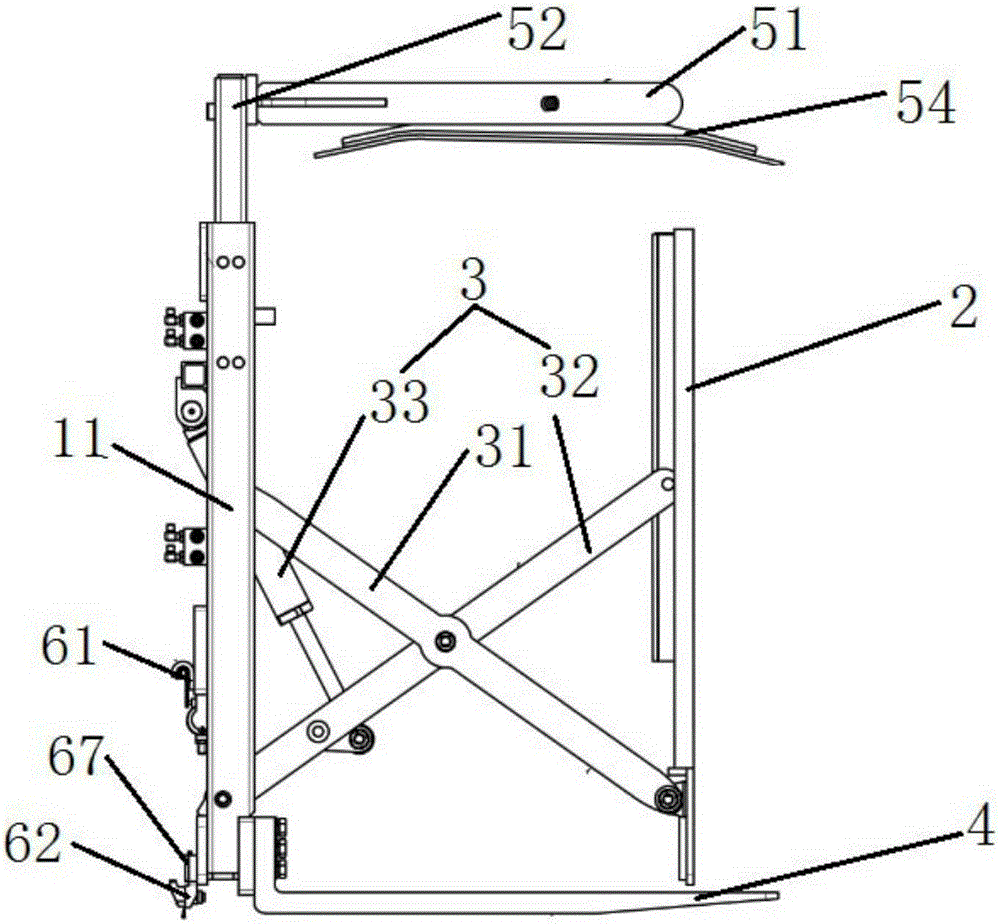

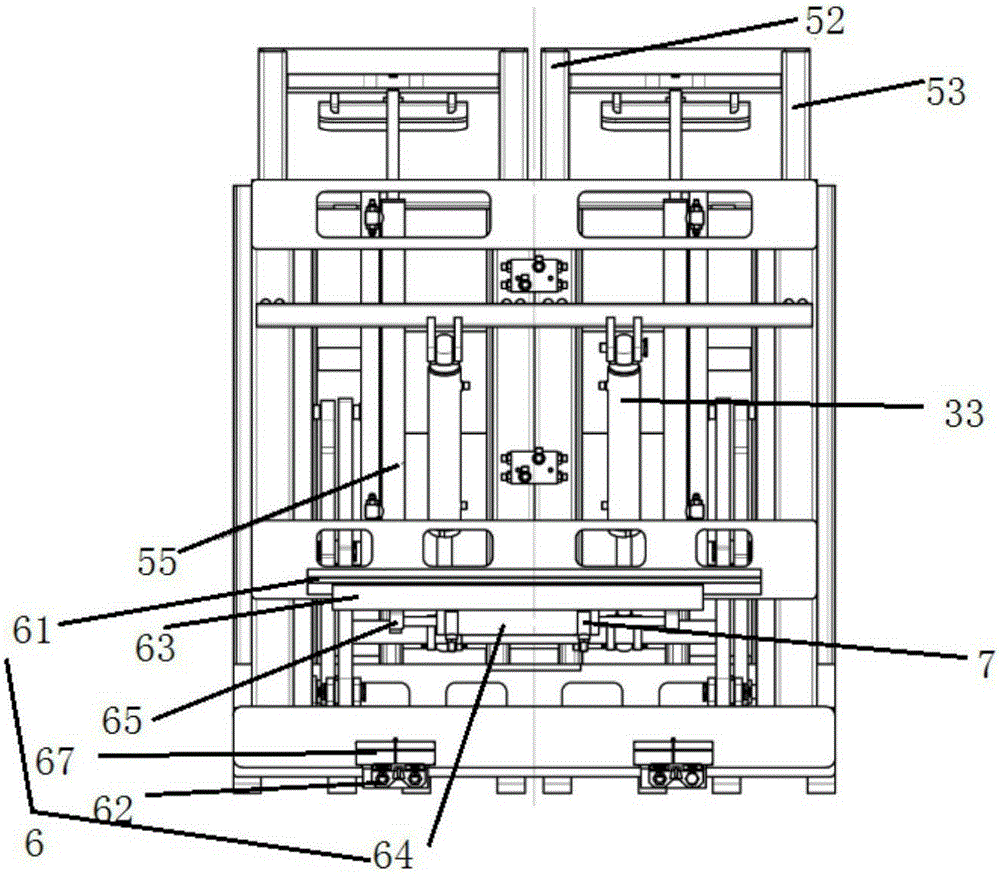

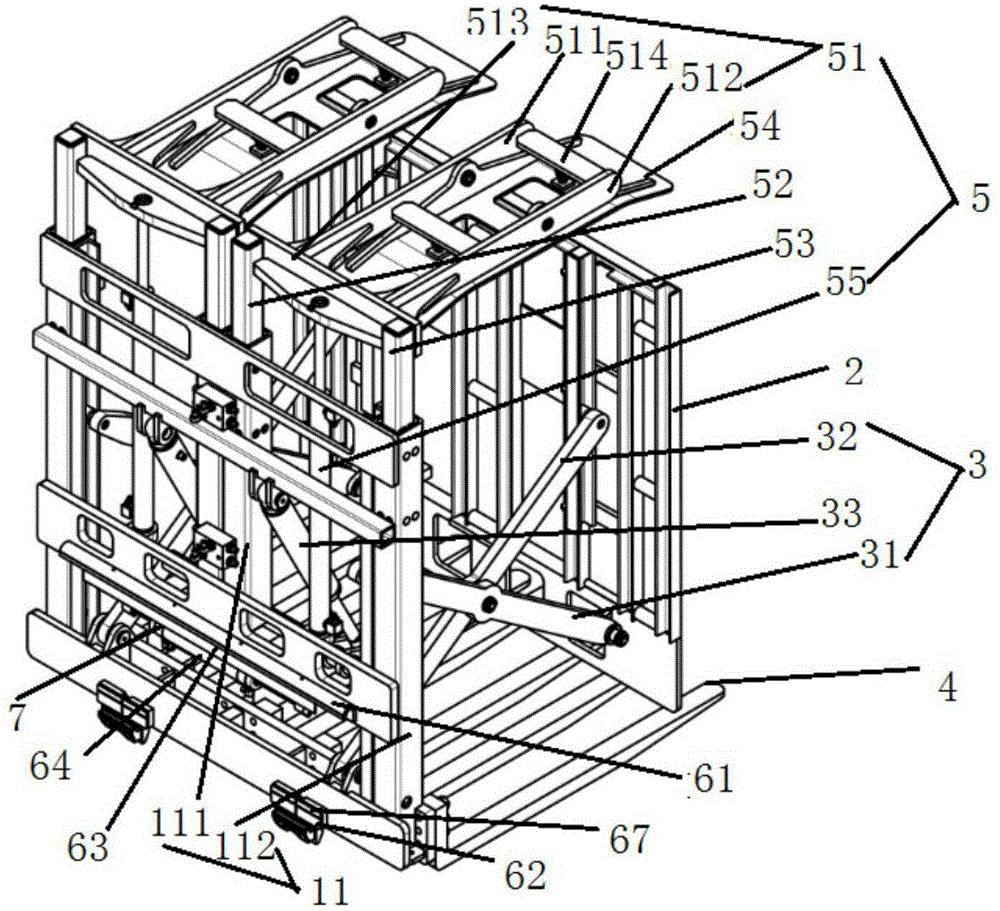

Push stabilizing mechanism for forklift

InactiveCN105152092ARealize unloading workImprove stabilityLifting devicesMaterial consumptionEngineering

The invention discloses a push stabilizing mechanism for a forklift. The push stabilizing mechanism comprises a rear support assembly, a front push board assembly, push mechanisms, pallet forks and downward pressing mechanisms. One end of each push mechanism is hinged to the rear support assembly and the other end of each push mechanism is hinged to the front push board assembly. At least two pallet forks are arranged, one end of each pallet fork is connected with the rear support assembly through bolts, and the other end of each pallet fork extends to the position below the front push board assembly. The rear support assembly comprises multiple hollow rod assemblies which are vertically arranged. Each hollow rod assembly comprises a first hollow rod and a second hollow rod which are arranged symmetrically. The push stabilizing mechanism further comprises the multiple downward pressing mechanisms. The downward pressing mechanisms comprise pressing rod assemblies, first movable rods, second movable rods, pressing boards and pressing oil cylinders. The push stabilizing mechanism has the adaptability to forked goods, good in stabilization, convenient to machine and assemble, capable of easily controlling the overall flatness of the pallet forks, convenient to detach and install, short in machining time, small in material consumption, optimal in performance and durable.

Owner:ANQING LIANDONG ENG TRUCKS ATTACHMENTS

Coaxial connector

InactiveCN102916285AFlatness is easy to controlHold firmlySoldered/welded conductive connectionsCoupling contact membersBiochemical engineeringInjection moulding

The invention discloses a coaxial connector. The coaxial connector comprises an insulation body, a conductive terminal arranged on the insulation body and a metal housing arranged on the outer side of the insulation body, wherein the insulation body is arranged at the inner side of the metal housing by injection; a flat base part and a butting part integrally and perpendicularly extending to one side from the base part are arranged on the insulation body; the butting part is provided with a receiving part for insertion of a butting connector; a mounting groove communicated with the receiving part is arranged in the base part; the conductive terminal is assembled and combined onto the insulation body through the mounting groove; and the metal housing is provided with a welding part which is embedded in the base part, is far away from one side of the butting part and is exposed outwards.

Owner:KUNSHAN JIAHUA ELECTRONICS

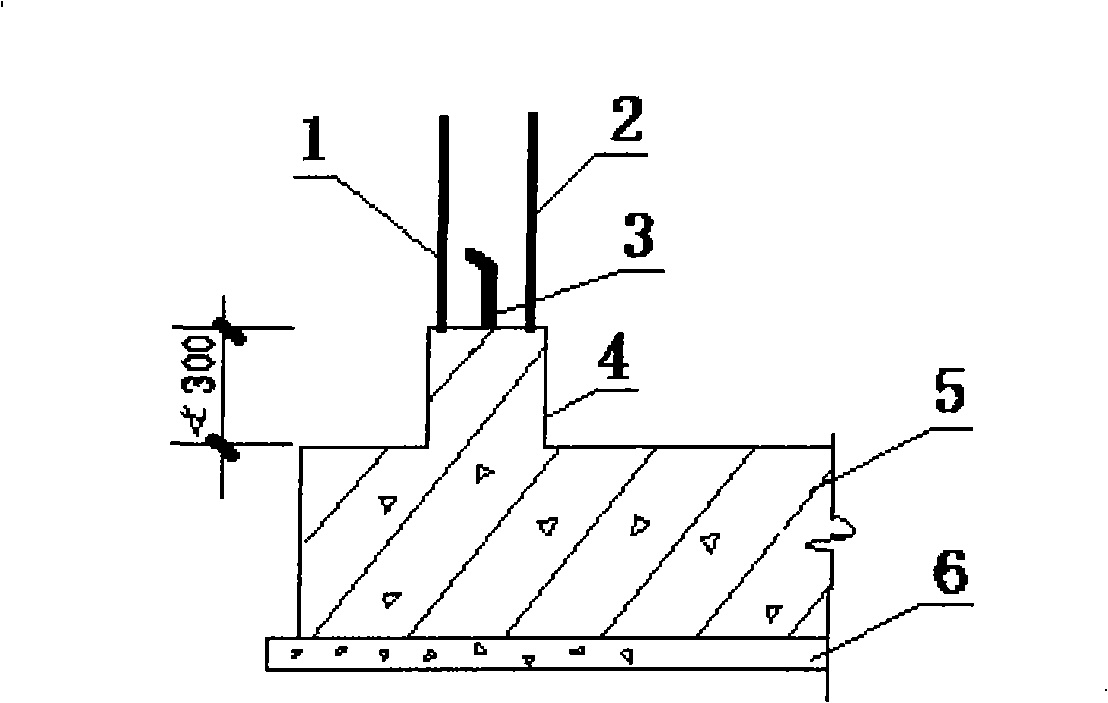

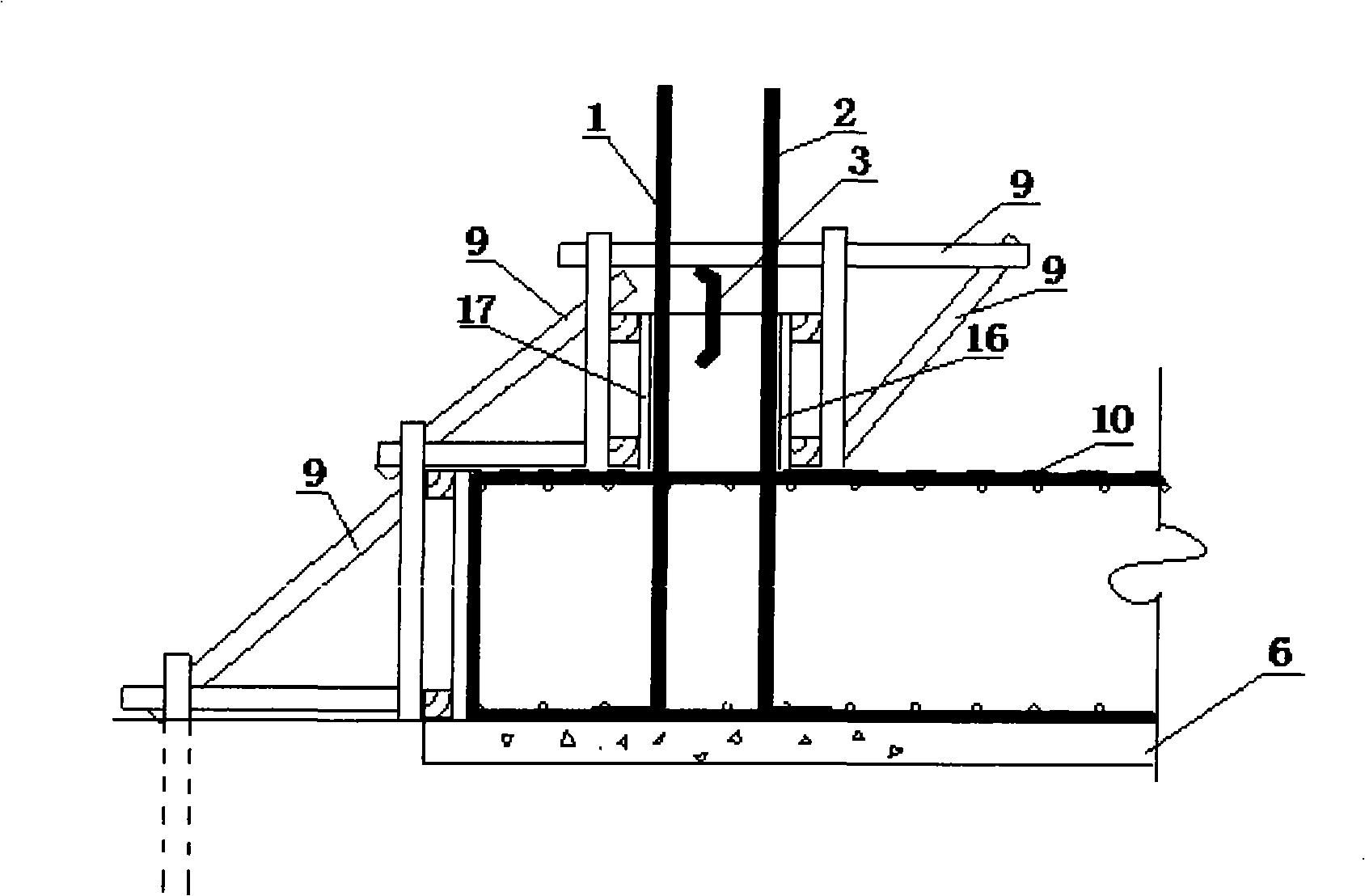

Underground cast-in-place concrete structure outer wall neck construction method

InactiveCN101265704AEasy to smoothTo achieve the effect of fair-faced concreteArtificial islandsUnderwater structuresEngineeringRebar

The invention discloses an external wall neck construction method of the underground cast-in-situ concrete structure, which includes the following steps: (1) arranging reinforced bars, wall body external steel bars and wall body internal steel bars on a bedding course, arranging a first exterior sheathing composed of a multilayer board and a square timber outside the wall body external steel bars in the method of external suspended form supporting formwork; (2) arranging the first exterior sheathing composed of the multilayer board and the square timber inside and fixedly connecting with the wall body internal steel bars, arranging a water-stopping steel plate between the wall body external steel bars and the wall body internal steel bars; (3) casting the concrete and finishing the underground cast-in-situ concrete structure external wall neck construction. The method enables a calendering operation of the upper surface of a foundation plate through surface rolling mechanically or manually, and enables the wall foot of the wall neck to be conveniently rolled to achieve the process requirement of one-step operation of casting and rolling together and the effect of exposed concrete. The method is easy, practical and economic, and the flatness can be controlled.

Owner:TIANJIN CONSTR ENG MAIN CONTRACTING

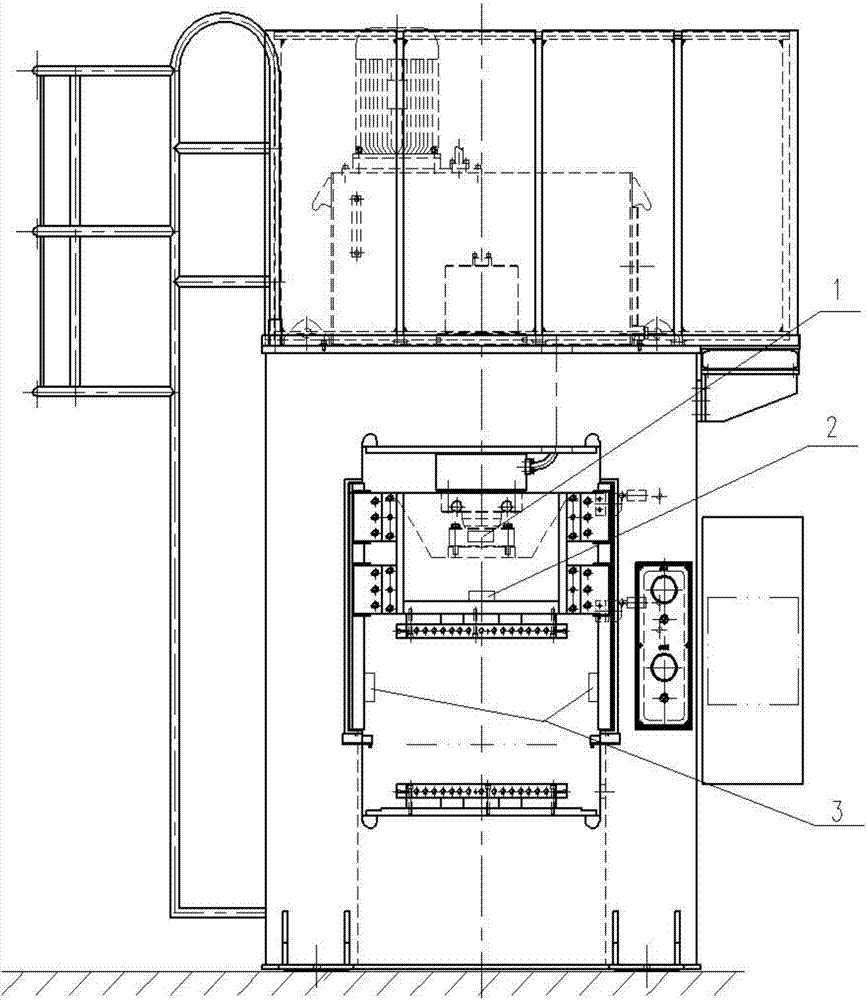

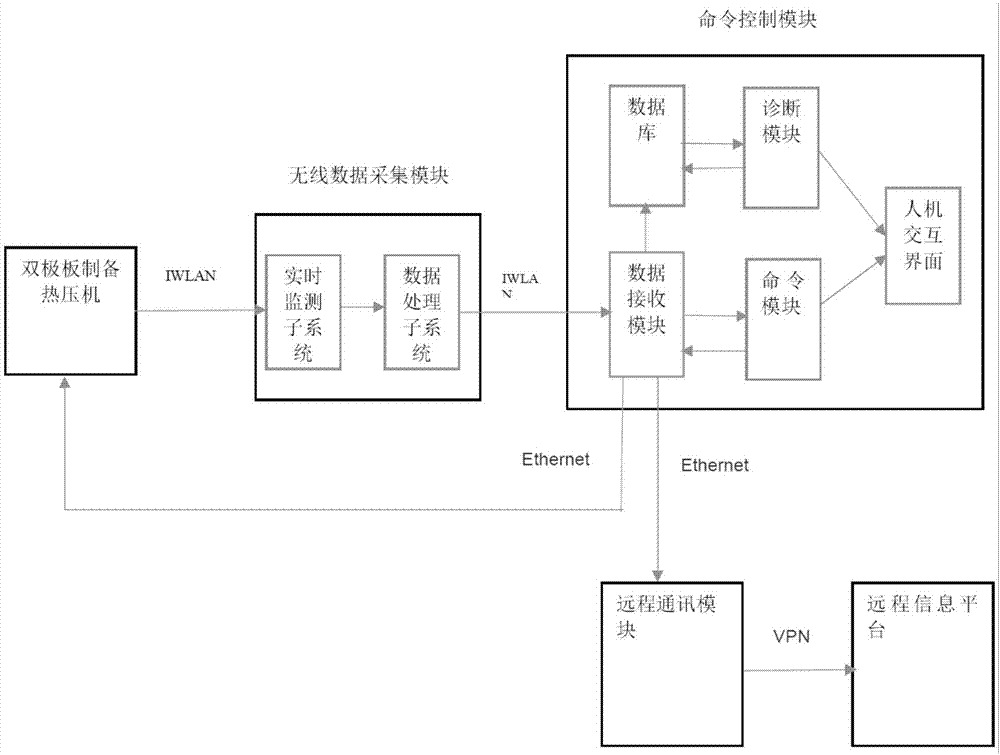

Remote control and diagnosis system of bipolar plate preparation hot press machine, and remote control and diagnosis method of bipolar plate preparation hot press machine

ActiveCN107065840AAchieving State ControllabilityControllable punching speedProgramme controlElectric testing/monitoringRemote controlEngineering

The invention discloses a remote control and diagnosis system of a bipolar plate preparation hot press machine, and a remote control and diagnosis method of the bipolar plate preparation hot press machine. The system comprises a wireless data acquisition module, a command control module, a remote communication module and a remote communication platform. The wireless data acquisition module obtains three real-time parameters of the bipolar plate preparation hot press machine: a stamping speed, slide block flatness and temperature of a hot press board. The command control module makes a corresponding comparison of each real-time parameter with a corresponding working range and then makes corresponding judgments: when any real-time parameter exceeds the corresponding working range, power-off is executed on the bipolar plate preparation hot press machine, a fault state diagnosis is performed on state data of the bipolar plate preparation hot press machine, and a fault type of the bipolar plate preparation hot press machine is output so that maintenance is perform by a worker according to the fault type. A remote session between the remote communication platform and the command control module is achieved through the remote communication module, and remote expert consultation is performed on the real-time parameters, so a state of the bipolar plate preparation hot press machine is reanalyzed.

Owner:HEFEI UNIV OF TECH

Ceramic tile prepared from waste materials and preparation method of ceramic tile

PendingCN113788668AAchieve re-useReduce manufacturing costCeramic materials productionClaywaresSlurryWaste material

The invention relates to the technical field of ceramics, and discloses a ceramic tile prepared from waste materials and a preparation method of the ceramic tile, and the preparation method comprises the following steps: carrying out filter pressing on artificial stone polishing residues and ceramic polishing residues, conducting soaking in a resin dispergator, conducting precipitating, carrying out filter pressing, and conducting uniform stirring to obtain artificial stone treatment residues and ceramic treatment residues; mixing the plastic raw material, the waste residue, a non-plastic raw material, a reinforcing auxiliary material and water, and carrying out ball milling and aging to obtain slurry; carrying out spray granulation on the slurry to obtain powder, carrying out compression molding, and conducting drying to obtain a ceramic green body; and carrying out silk-screen printing and ink-jet printing on the ceramic green body, conducting glazing and then conducting firing to obtain the ceramic tile manufactured by utilizing the waste materials. The ceramic polishing slag, the artificial polishing stone and the filter pressing mud in the waste slag are used as one of the main preparation raw materials of the ceramic green body, so that the solid waste material is recycled, the energy is saved, the environment is protected, the production cost is reduced, meanwhile, the influence on the performance of a ceramic tile finished product is small, and the breaking strength and the water absorption rate are better improved.

Owner:FOSHAN CITY GANI CERAMICS CO LTD

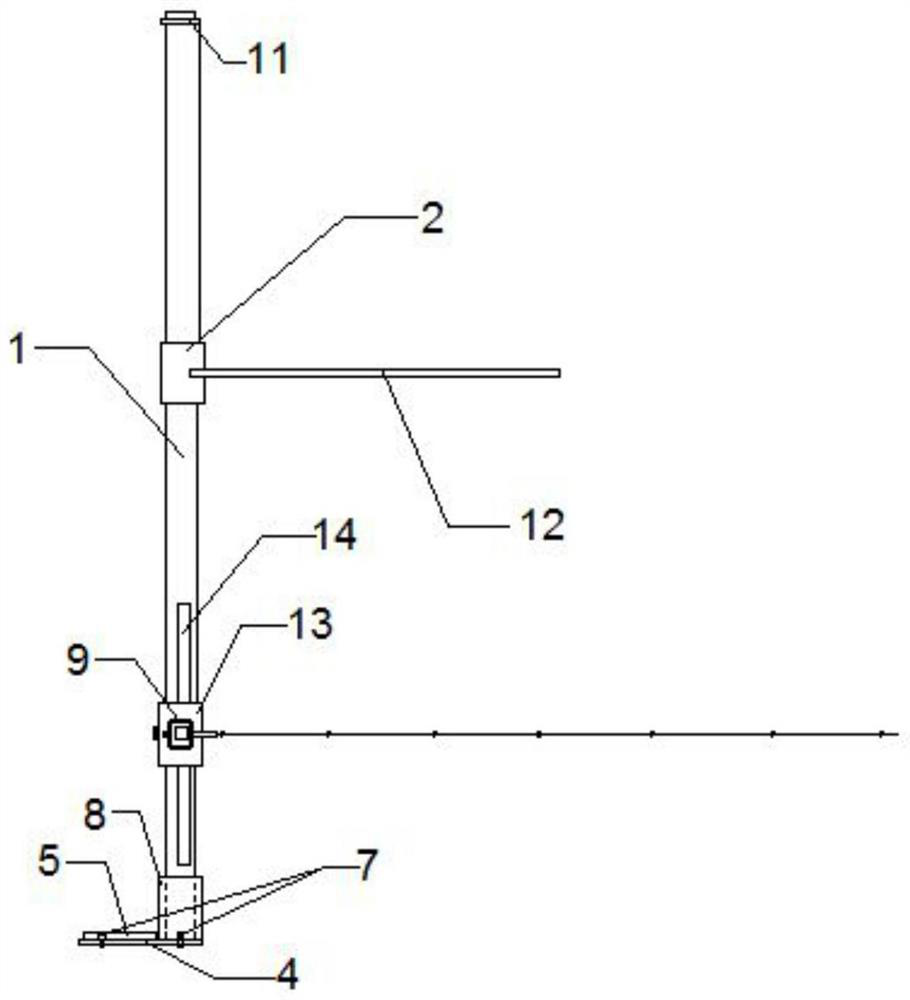

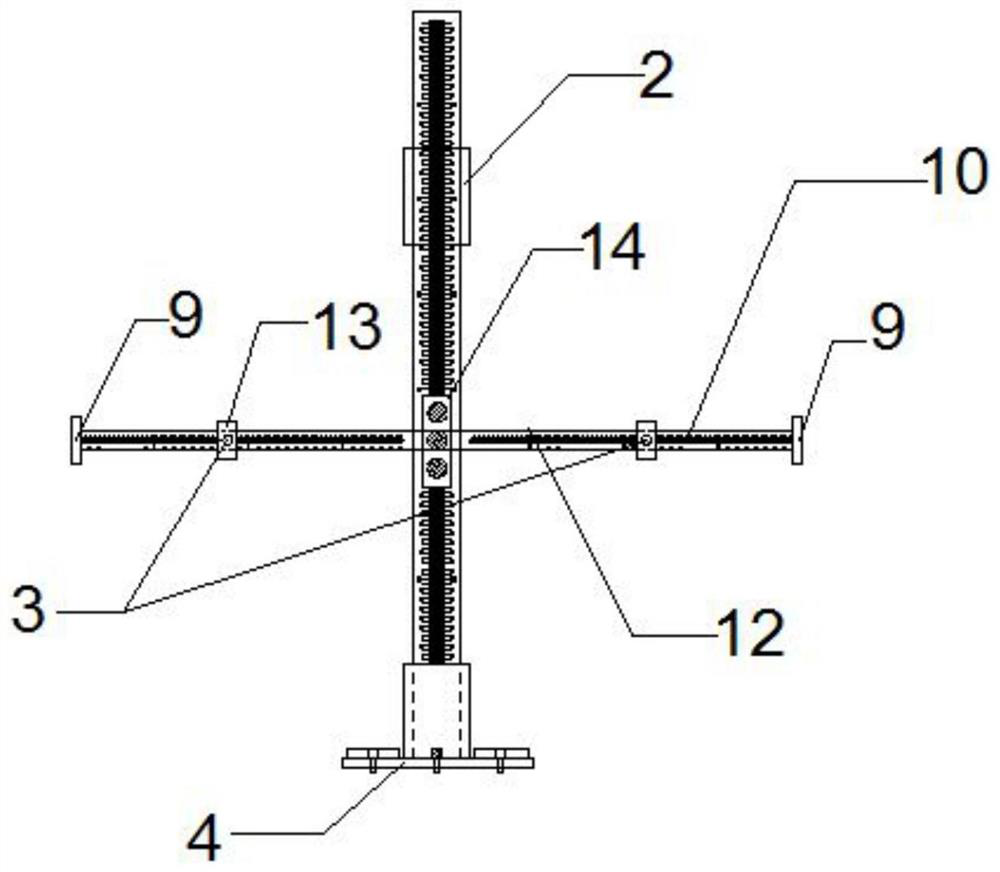

Laser height pole device capable of controlling flatness of masonry

InactiveCN111636695AAccurate length measurementAccurate width measurementBuilding material handlingStructural engineeringControl theory

The invention discloses a laser height pole device capable of controlling the flatness of masonry. The laser height pole device capable of controlling the flatness of the masonry comprises a levelingbase, a vertical rod is fixedly connected to the leveling base, the vertical rod is perpendicular to the leveling base, and a cross rod is fixedly connected to the vertical rod. The cross rod and thevertical rod are perpendicular to each other; the vertical rod is movably connected with a sleeve, the sleeve is located above the cross rod, the sleeve is fixedly connected with a longitudinal measuring rod, the longitudinal measuring rod is perpendicular to the vertical rod, and a vertical rod limiting block is arranged at the top end of the vertical rod; the vertical rod, the cross rod and thelongitudinal measuring rod are all height poles, the vertical rod, the cross rod and the longitudinal measuring rod are all telescopic rods, and the leveling base is in bolted connection with a vertical rod inserting cylinder; and the vertical rod is fixedly connected with a leveling base plate through an inserting groove, the leveling base is in bolted connection with a counterweight, and the leveling base is in bolted connection with a horizontal air bubble meter. The laser height pole device capable of controlling the flatness of the masonry has the advantages of high precision, rich functions, simple operation, convenient carrying and use and the like. The laser height pole device capable of controlling the flatness of the masonry has the function of controlling the flatness of the masonry wall.

Owner:CHINA MCC17 GRP

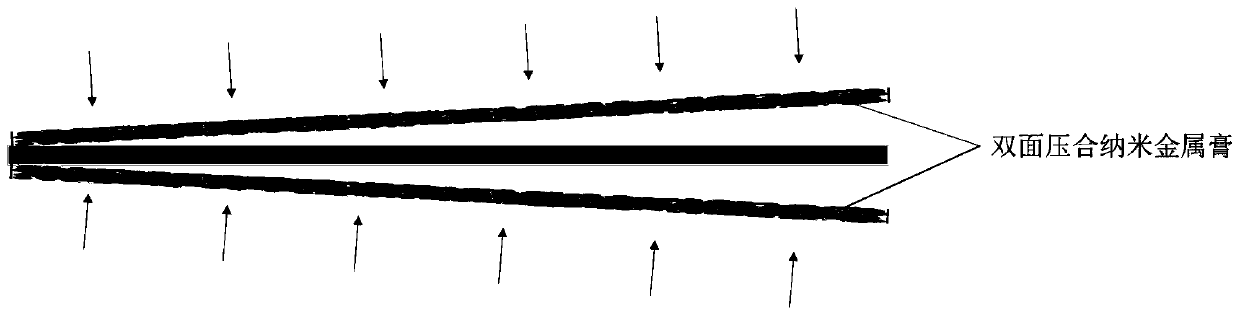

Novel die bonding material and packaging structure thereof

ActiveCN111415914AImprove uniformityFlatness is easy to controlMaterial nanotechnologySemiconductor/solid-state device detailsActive agentMetal particle

The invention discloses a novel die bonding material and a packaging structure, and the die bonding material comprises a nano metal paste film and a heat dissipation layer, wherein the nano metal paste film uniformly covers at least one of the upper surface and the lower surface of the heat dissipation layer; the heat dissipation layer is of a multi-layer graphene structure, and the nano metal paste film comprises nano metal particles, an antioxidant, soldering flux, a stabilizer and an active agent; the content of the nano metal particles is 50.0 wt.%-95.0 wt.%, the content of the antioxidantis 5.0 wt.%-40.0 wt.%, and the total amount of the scaling powder, the stabilizer and the active agent is less than or equal to 5.0 wt.%. The material has the characteristics of high heat dissipationand uniform thickness; on the premise that the electrical performance of the semiconductor packaging interconnection module is not affected, die bonding and interconnection under the low-temperaturecondition are achieved, the semiconductor packaging interconnection module can be used under the conditions of small spacing, high power, high temperature, high pressure and the like, and the semiconductor packaging interconnection module can be widely applied to the fields of power electronics, IGBT packaging, photoelectron packaging, MEMS packaging, microelectronics, high-power LED packaging andthe like.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

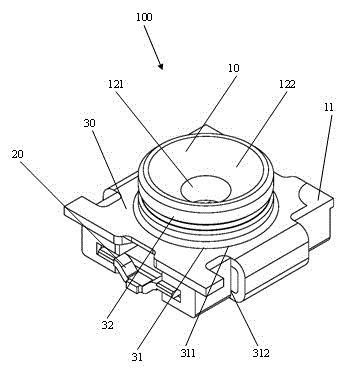

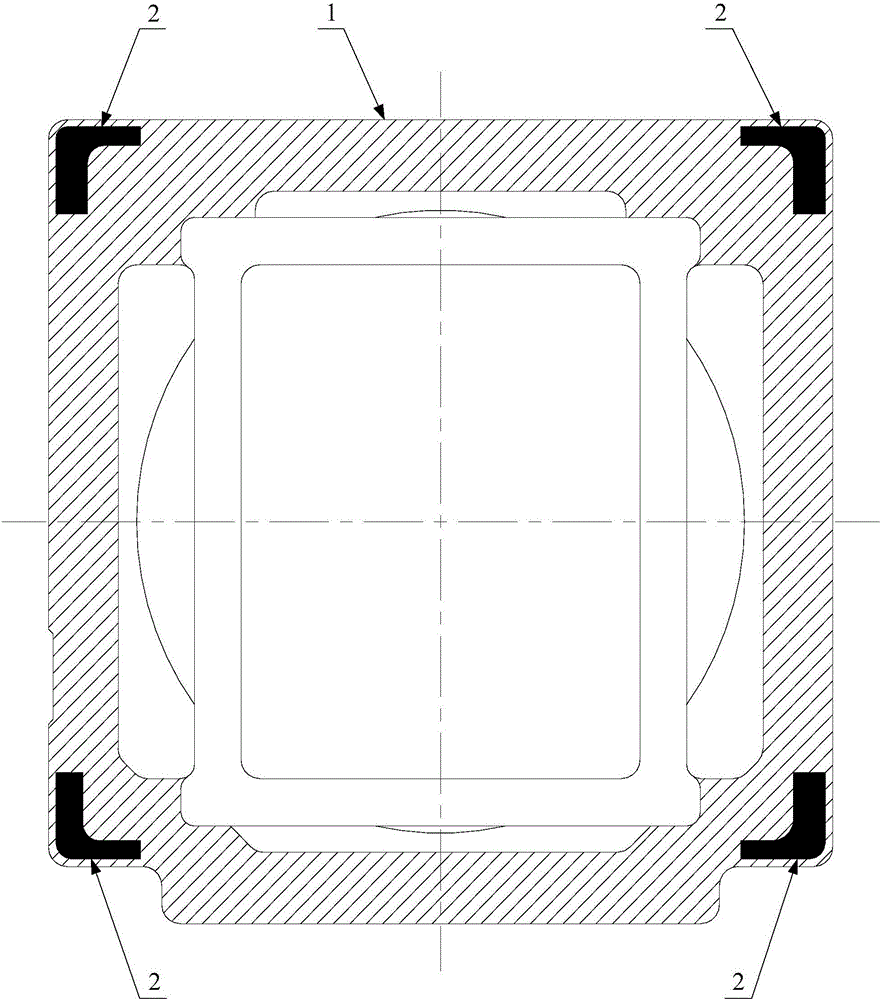

Camera module and connection base thereof

InactiveCN106161908AFlatness is easy to controlImprove imaging effectTelevision system detailsColor television detailsHeight differenceCamera module

The invention discloses a connection base which comprises a base body and bosses, wherein the bosses are arranged on the base body, protruded out of the surface of the base body, and connected with components of a camera module; the area of the top surface of each boss is less than the areas of the top surface and the bottom surface of the base. According to the connection base provided by the invention, the area of the top surface of each boss is less than the area of the whole top surface of the base body and also less than the area of the whole bottom surface of the base body, so that the flatness of the top surface of each boss is easier to control, and the four-corner height difference caused by mutual matching is reduced; therefore, the error of the flatness of the top surface among all the bosses can be reduced, and even eliminated, the phenomenon of different definitions of the four corners in an imaging process of the camera module is avoided, and the shooting effect of the camera module is further enhanced. The invention further provides the camera module provided with the connection base.

Owner:TRULY OPTO ELECTRONICS

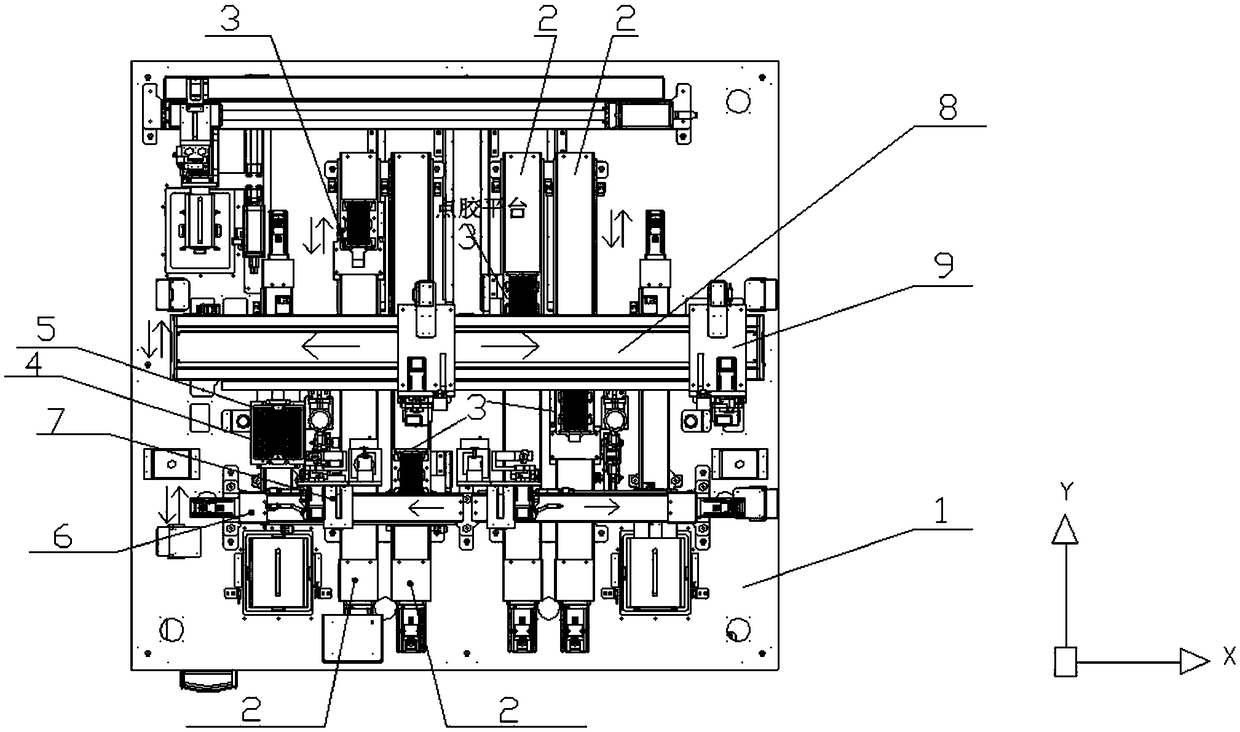

Linear quartz crystal resonator adhesive dispensing mechanism and operation method

PendingCN108722800AFlatness is easy to controlEasy to get on and offLiquid surface applicatorsCoatingsQuartz crystal resonatorTransfer mechanism

The invention discloses a linear quartz crystal resonator adhesive dispensing mechanism and an operation method. The linear quartz crystal resonator adhesive dispensing mechanism comprises a rack andadhesive dispensing platform linear motion shafts disposed on the rack, each adhesive dispensing platform linear motion shaft is equipped with an adhesive dispensing platform, one sides of the adhesive dispensing platform linear motion shafts are equipped with an adhesive dispensing material tray, and quartz crystal resonator bases are disposed on the adhesive dispensing material tray, an adhesivedispensing head motion shaft perpendicular to the adhesive dispensing platform linear motion shaft is disposed thereabove, the adhesive dispensing head motion shaft is equipped with adhesive dispensing heads, a transfer shaft parallel to the adhesive dispensing head motion shaft is disposed thereabove, and the transfer shaft is equipped with material tray transfer mechanisms. The invention solvesthe problems of high flatness requirement for platform and difficult control of flatness in the circular turntable multi-station production mode of the prior art.

Owner:绍兴奥美电子科技有限公司

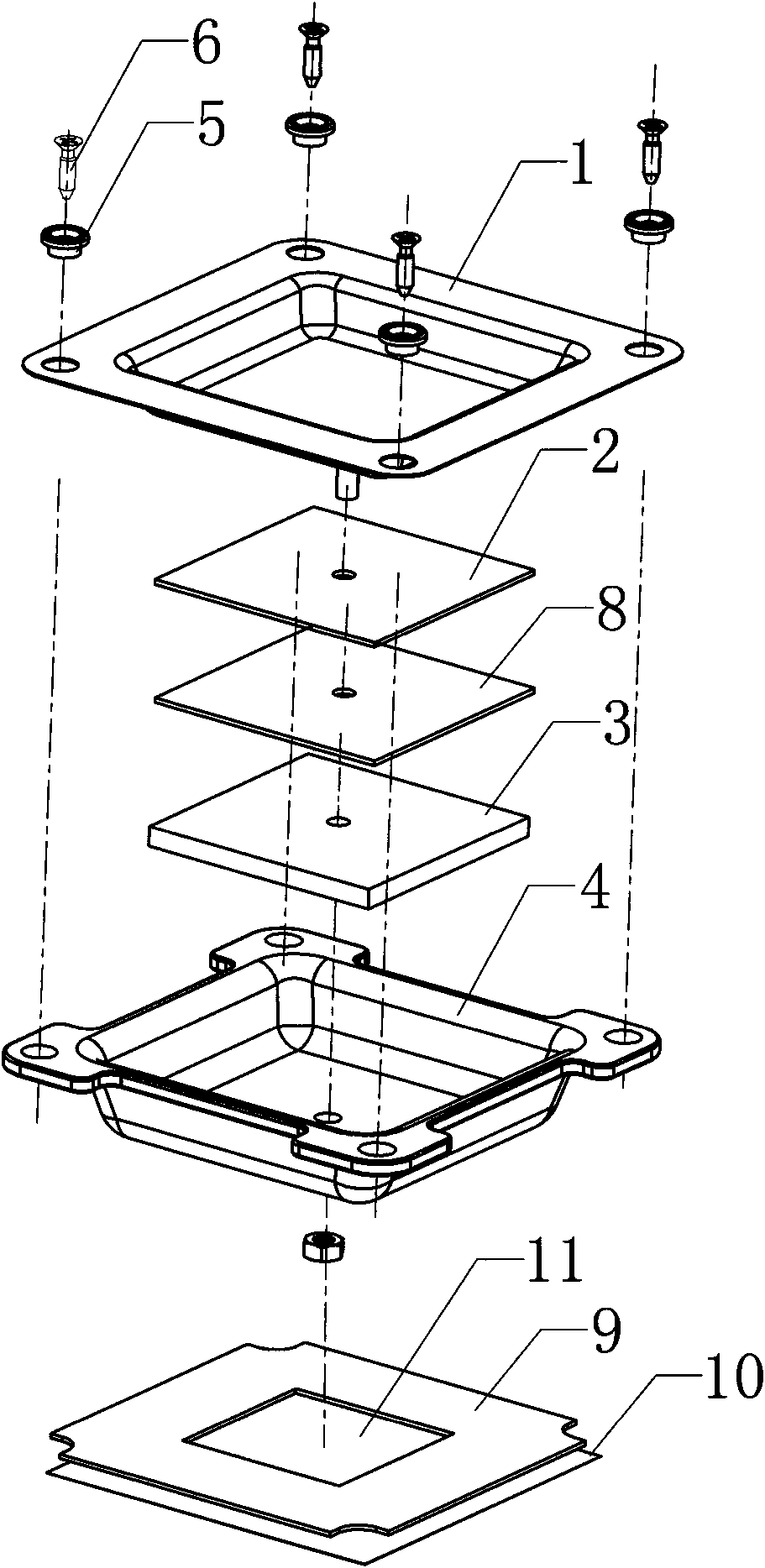

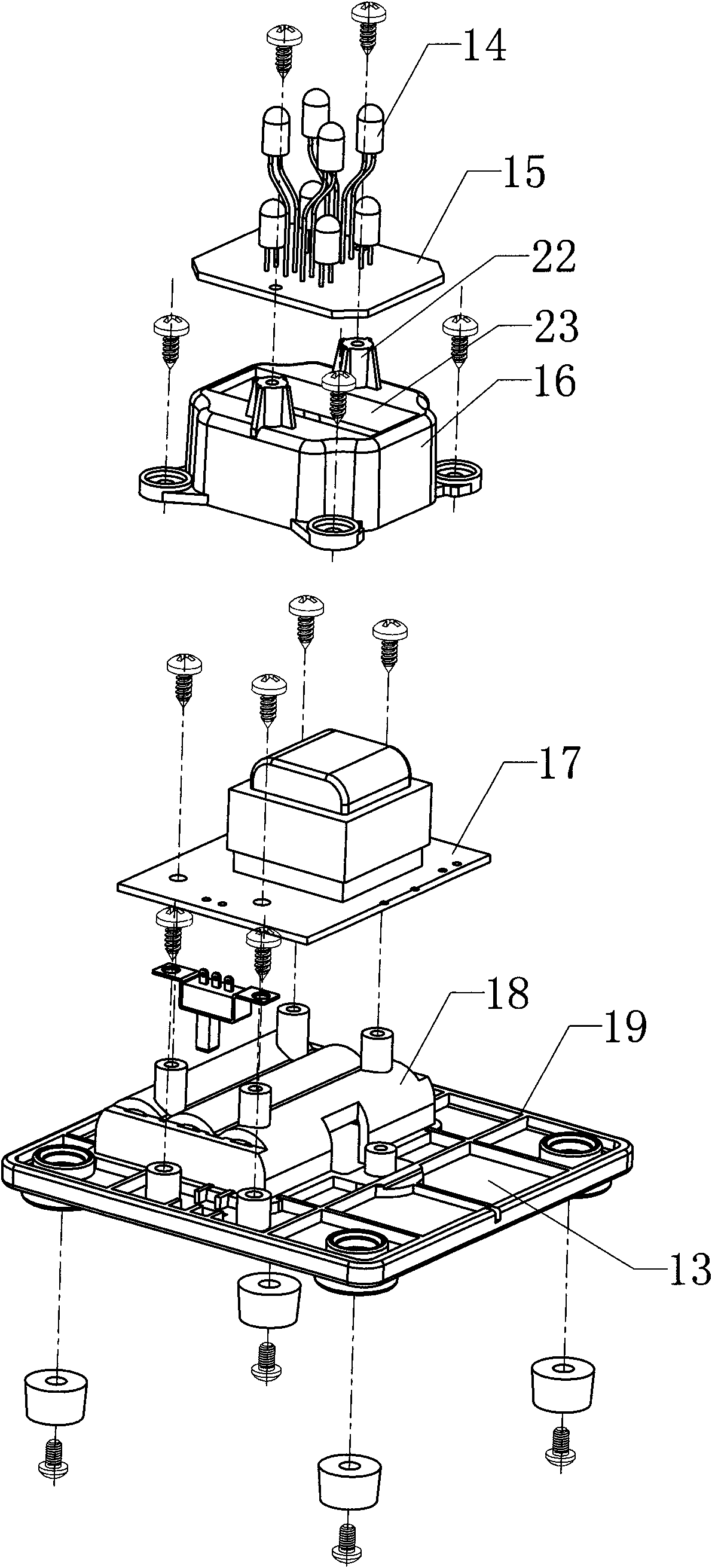

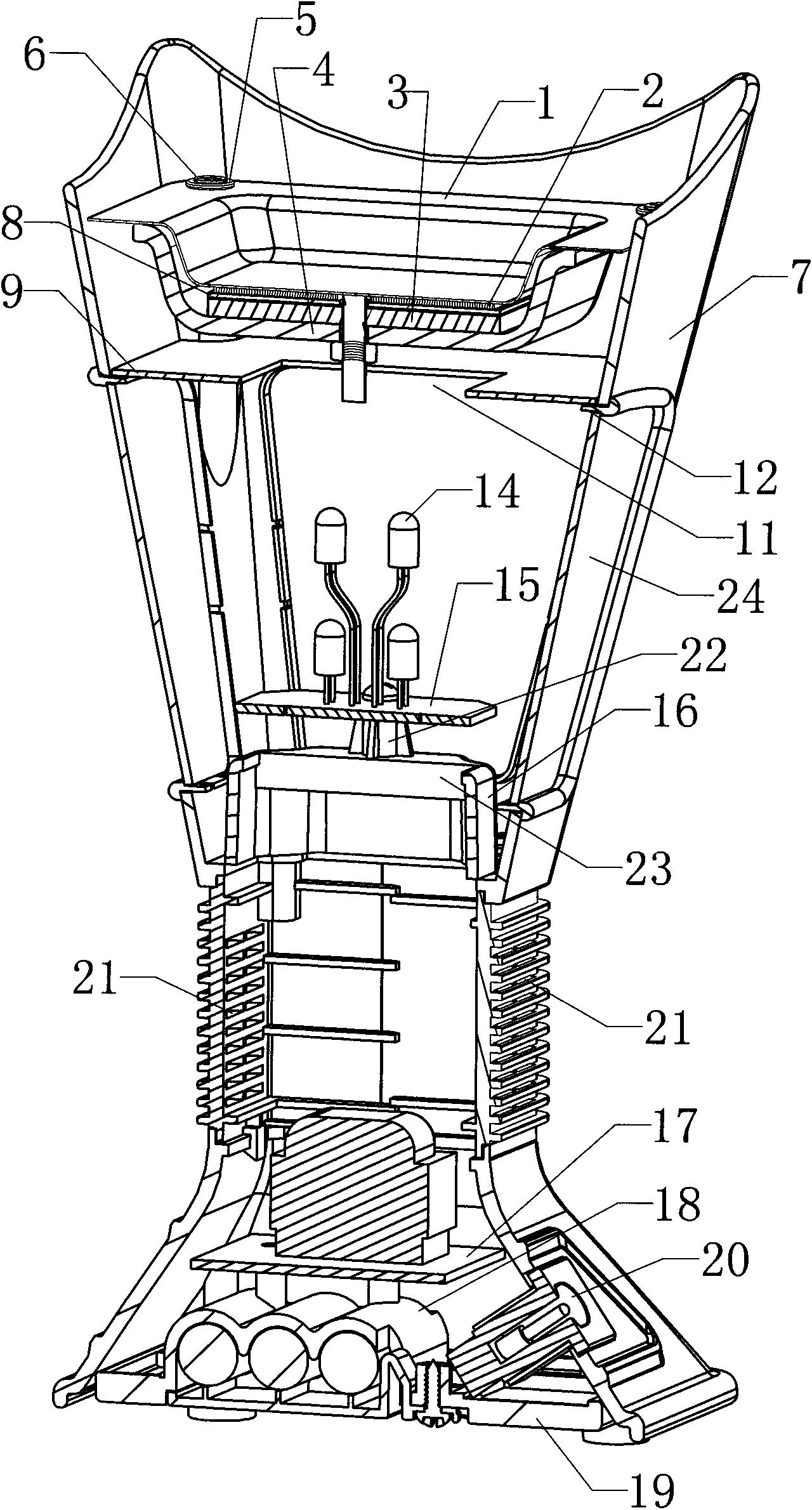

Electronic incense furnace

InactiveCN102178969AReduce the temperatureImprove cooling effectGaseous substancesEngineeringHeat conducting

Owner:NINGBO APG APPLIANCE & TECH CO LTD

Probe card and wafer test system

PendingCN113484561AFlatness is easy to controlGuaranteed flatnessElectrical measurement instrument detailsAutomated test systemsProbe cardTest region

The invention provides a probe card and a wafer test system. The probe card comprises a PCB; a ceramic substrate arranged on the PCB; a probe head arranged on the ceramic substrate, wherein the probe head comprises a guide plate, and a plurality of uniformly distributed probes are arranged on the guide plate; wherein an insertion plate is arranged between the PCB and the ceramic substrate, a plurality of spring needles penetrating through the insertion plate are arranged on the insertion plate, and the two ends of each spring needle are fixedly connected with the PCB and the ceramic substrate respectively. According to the probe card, the flatness of the tip of the probe can be ensured while the test area is increased, so that the test of a wafer is facilitated.

Owner:上海泽丰半导体科技有限公司

A prefabricated wall panel and beam body precise positioning installation connection structure

InactiveCN103758213BImprove mechanical propertiesReduce the amount of aerial workBuilding constructionsReinforced concreteEngineering

The invention discloses a precise locating mounting connecting structure of assembled wall boards and a beam body, and belongs to the field of assembled building connecting structures. A pre-buried C-type steel sliding groove component is arranged on a side bearing table of a reinforced concrete precast beam, and two C-type steel sliding grooves of the pre-buried C-type steel sliding groove component are correspondingly exposed on the upper surface and the lower surface of the side bearing table; adjustable locating connecting pieces are groove type steel pieces, and transverse long-strip oval holes perpendicular to the groove edges are formed in the groove bottom faces of the adjustable locating connecting pieces; the two adjustable locating connecting pieces are connected and located with the C-type steel sliding grooves of the pre-buried C-type steel sliding groove component of the reinforced concrete precast beam respectively; due to the fact that the adjustable locating connecting pieces transversely and longitudinally move relative to the C-type steel sliding grooves, transverse and longitudinal moving adjustment and locating of the adjustable locating connecting pieces on the upper surface and the lower surface of the bearing table of the reinforced concrete precast beam can be achieved, prefabricated wall boards are correspondingly embedded into grooves in two ends of the upper adjustable locating connecting piece and the lower adjustable locating connecting piece respectively, and rapid locating and mounting of the assembled building wall boards in the prefabricated beam can be achieved.

Owner:HUBEI HONGYI STEEL CONSTR ENG

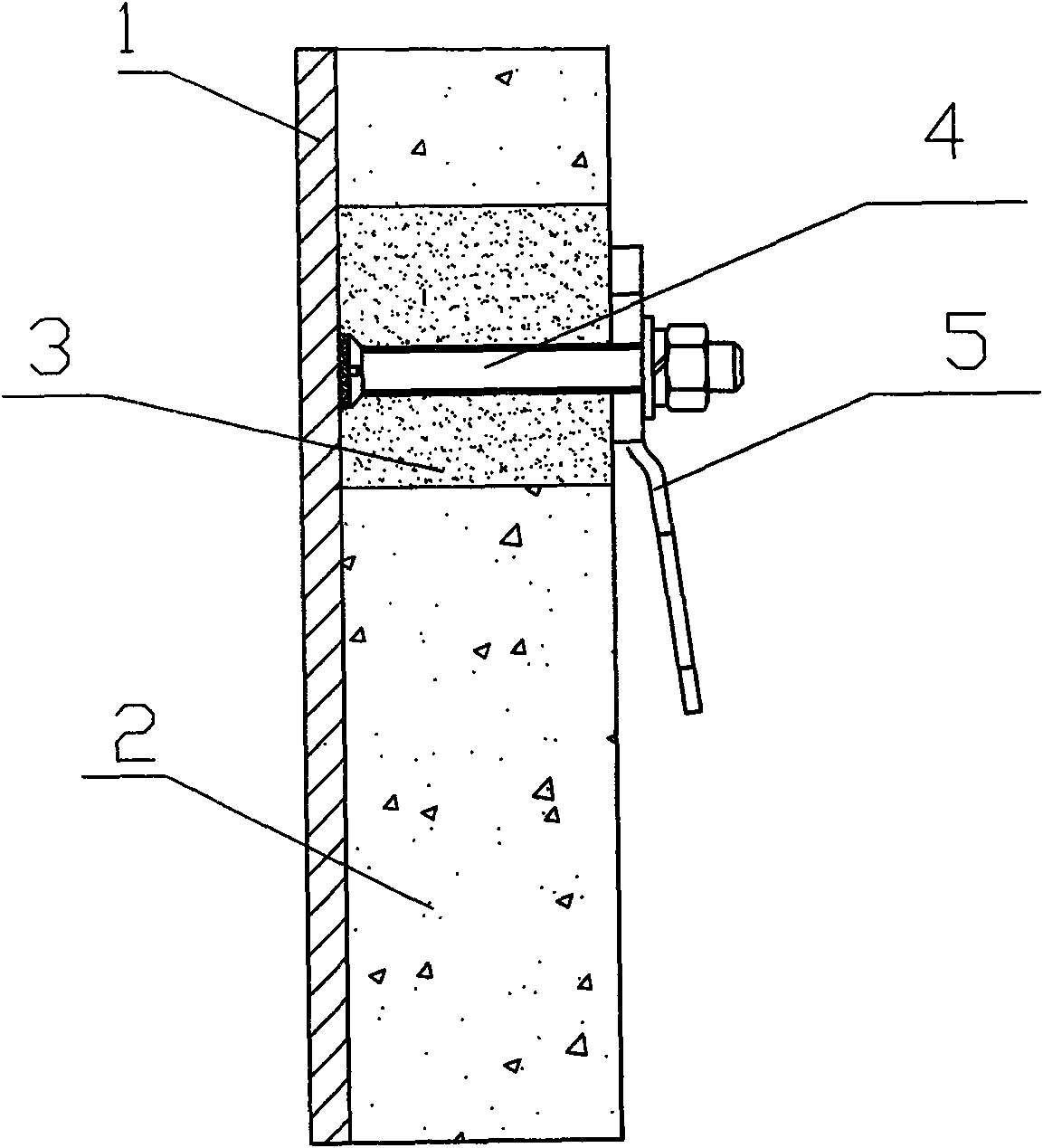

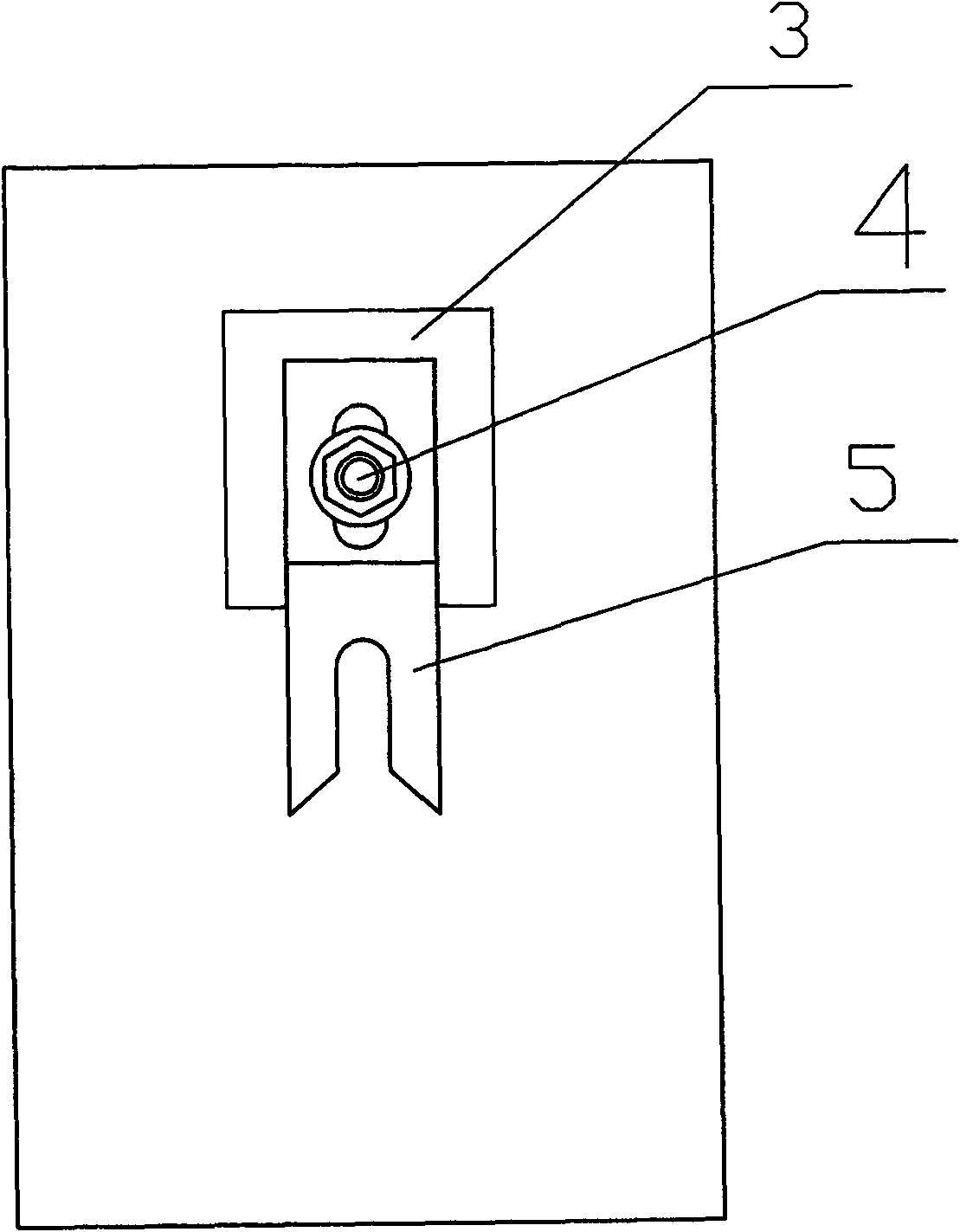

High-strength fireproofing heat-insulating decorative board provided with internal fixed connecting members

The invention discloses a high-strength fireproofing heat-insulating decorative board provided with internal fixed connecting members, which comprises a decoration layer, an ordinary heat-insulating layer is adhered on the back surface of the decoration layer, a plurality of fixed connecting members are arranged inside the fireproofing heat-insulating decorative board, a filling slot is arranged on the ordinary heat-insulating layer at the position on the fireproofing heat-insulating decorative board, where the internal fixed connecting members are arranged, light foaming material blocks matched with the filling slot are filled in the filling slot, and the internal fixed connecting members are fixed on the back surface of the decoration layer and in the light foaming material blocks. The high-strength fireproofing heat-insulating decorative board has the following benefits of high strength and hardness of the light foaming material blocks, easiness in manufacture, high mounting strength and easily controlled smoothness due to the adoption of the technical scheme; and the fireproofing heat-insulating decorative board does not fall off easily, thus potential safety hazard is eliminated.

Owner:王光胜

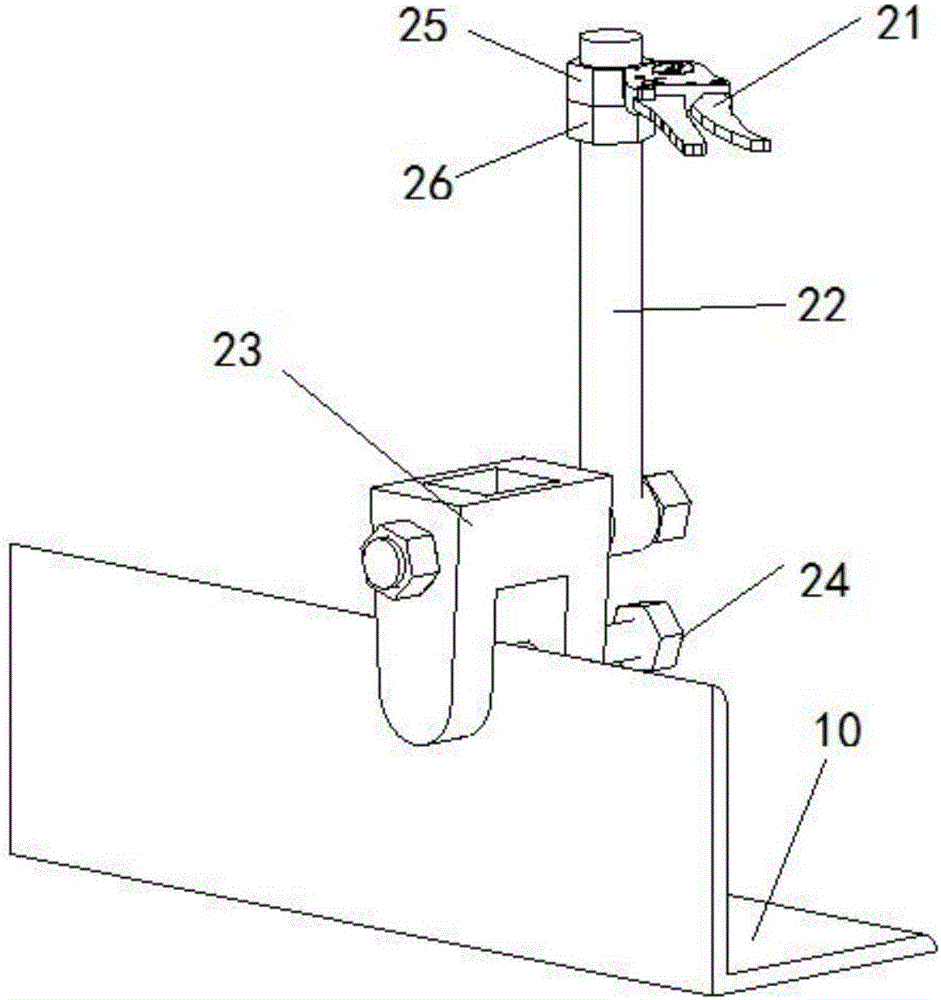

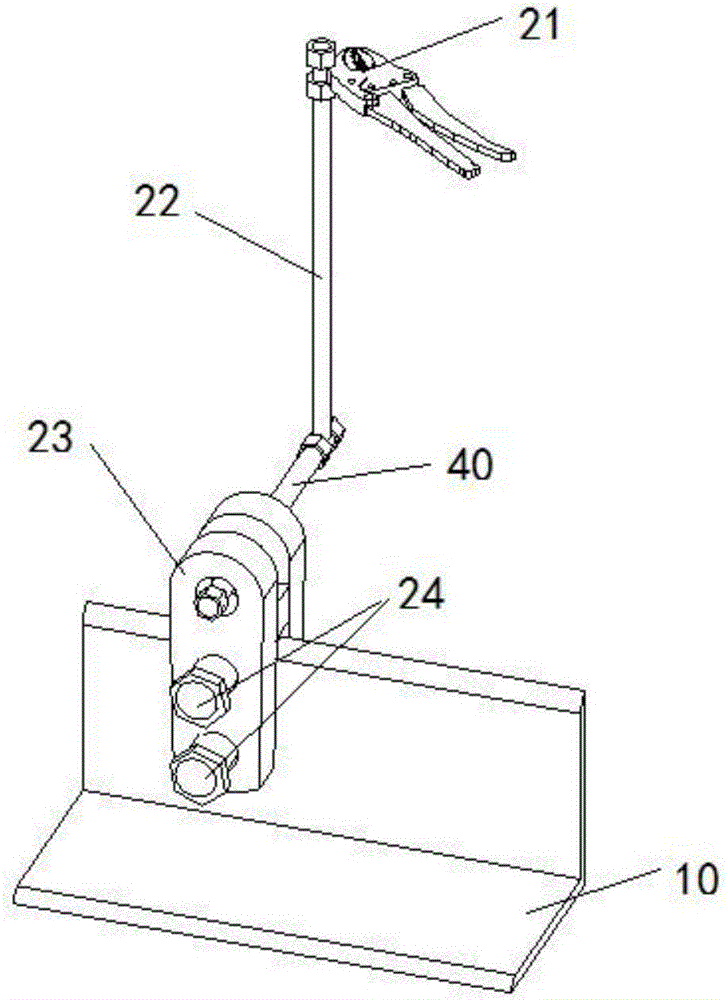

Wall panel hoisting tool and method

PendingCN112429632AThe hoisting implementation process is simple and easyImprove hoisting efficiencyBuilding material handlingLoad-engaging elementsEngineeringStructural engineering

Owner:SHANGHAI MECHANIZED CONSTR GRP

Underground cast-in-place concrete structure outer wall neck construction method

InactiveCN101265704BEasy to smoothTo achieve the effect of fair-faced concreteArtificial islandsUnderwater structuresEngineeringRebar

The invention discloses an external wall neck construction method of the underground cast-in-situ concrete structure, which includes the following steps: (1) arranging reinforced bars, wall body external steel bars and wall body internal steel bars on a bedding course, arranging a first exterior sheathing composed of a multilayer board and a square timber outside the wall body external steel barsin the method of external suspended form supporting formwork; (2) arranging the first exterior sheathing composed of the multilayer board and the square timber inside and fixedly connecting with the wall body internal steel bars, arranging a water-stopping steel plate between the wall body external steel bars and the wall body internal steel bars; (3) casting the concrete and finishing the underground cast-in-situ concrete structure external wall neck construction. The method enables a calendering operation of the upper surface of a foundation plate through surface rolling mechanically or manually, and enables the wall foot of the wall neck to be conveniently rolled to achieve the process requirement of one-step operation of casting and rolling together and the effect of exposed concrete.The method is easy, practical and economic, and the flatness can be controlled.

Owner:TIANJIN CONSTR ENG MAIN CONTRACTING

A combined mold and flange manufacturing process

ActiveCN104801639BHigh dimensional accuracyFlatness is easy to controlMetal rollingManufacturing technologyFlanging

The invention relates to the technical field of wind power flange manufacturing, in particular to an assembling die and a flanging manufacturing process. The assembling die comprises a preforming die and a forming die, wherein the preforming die is used for performing radial preforming rolling on the inner wall of an annular flange blank by adopting a semi-closure hole pattern; the forming die is used for performing radial forming rolling on the inner wall of the annular flange blank by adopting the semi-closure hole pattern; the preforming die comprises a quick-changing barrel; an upper baffle, an upper pre-die, a pre-cutting knife, a lower pre-die and a lower baffle sleeve the quick-changing barrel from top to bottom in sequence; the forming die comprises the quick-changing barrel; the upper baffle, an upper main die, a main cutting knife, a lower main die and a lower baffle sleeve the quick-changing barrel from top to bottom in sequence. The assembling die and the flanging manufacturing process disclosed by the invention, dimensional accuracy of rolling and ring rolling is increased, the flatness of the end face of a product can be conveniently controlled, and is increased; the product material and cost are reduced, and manufacturing is time-saving and labor-saving; the energy consumption of the process is low, the production efficiency is high, and the product quality is improved.

Owner:SHANXI DOUBLE RING HEAVY MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com