Electronic incense furnace

An electronic and incense burner technology, which is applied in the direction of vaporized substances, can solve the problems of service life and reliability reduction of lighting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described on the lower surface in conjunction with the accompanying drawings.

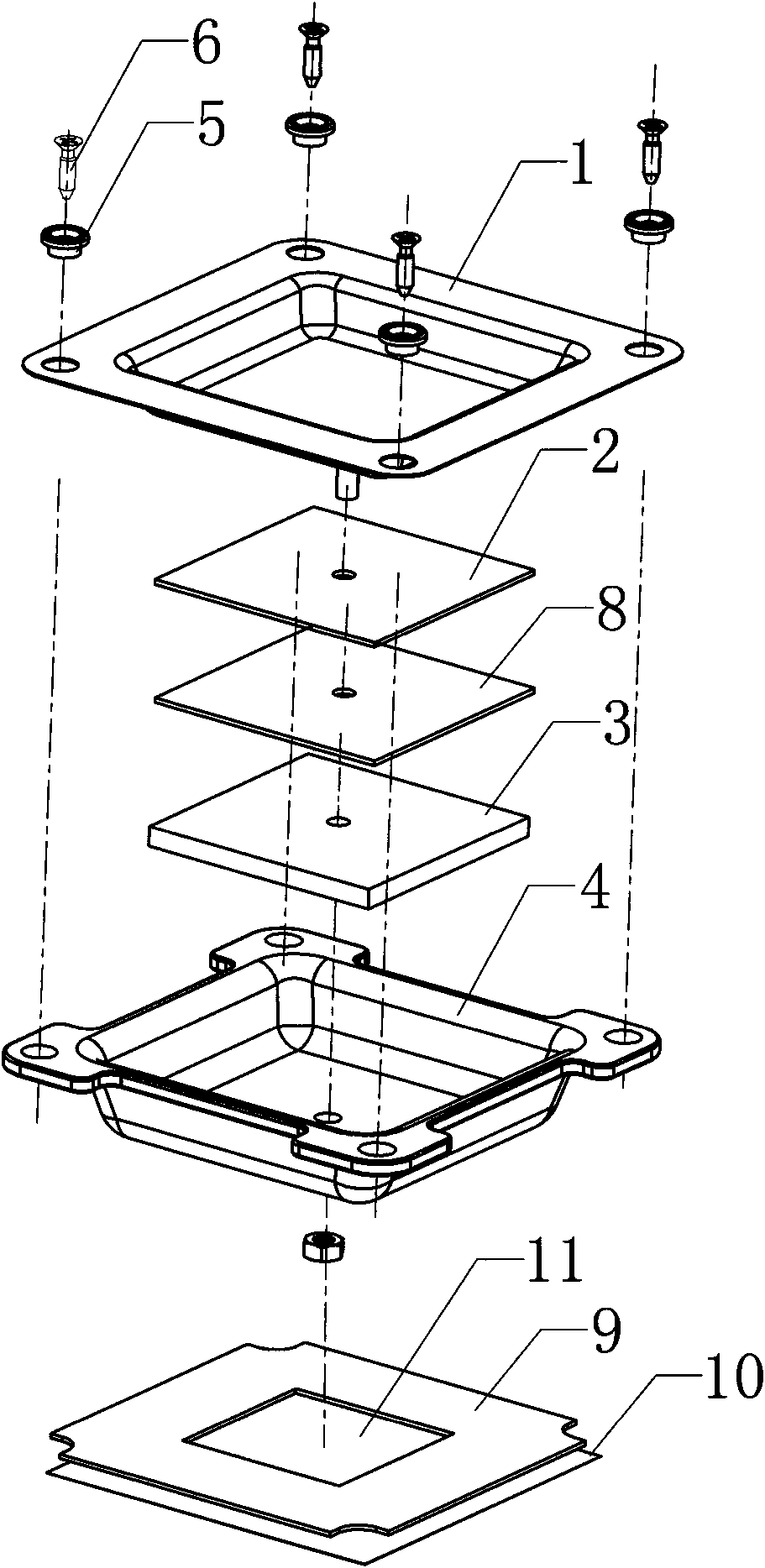

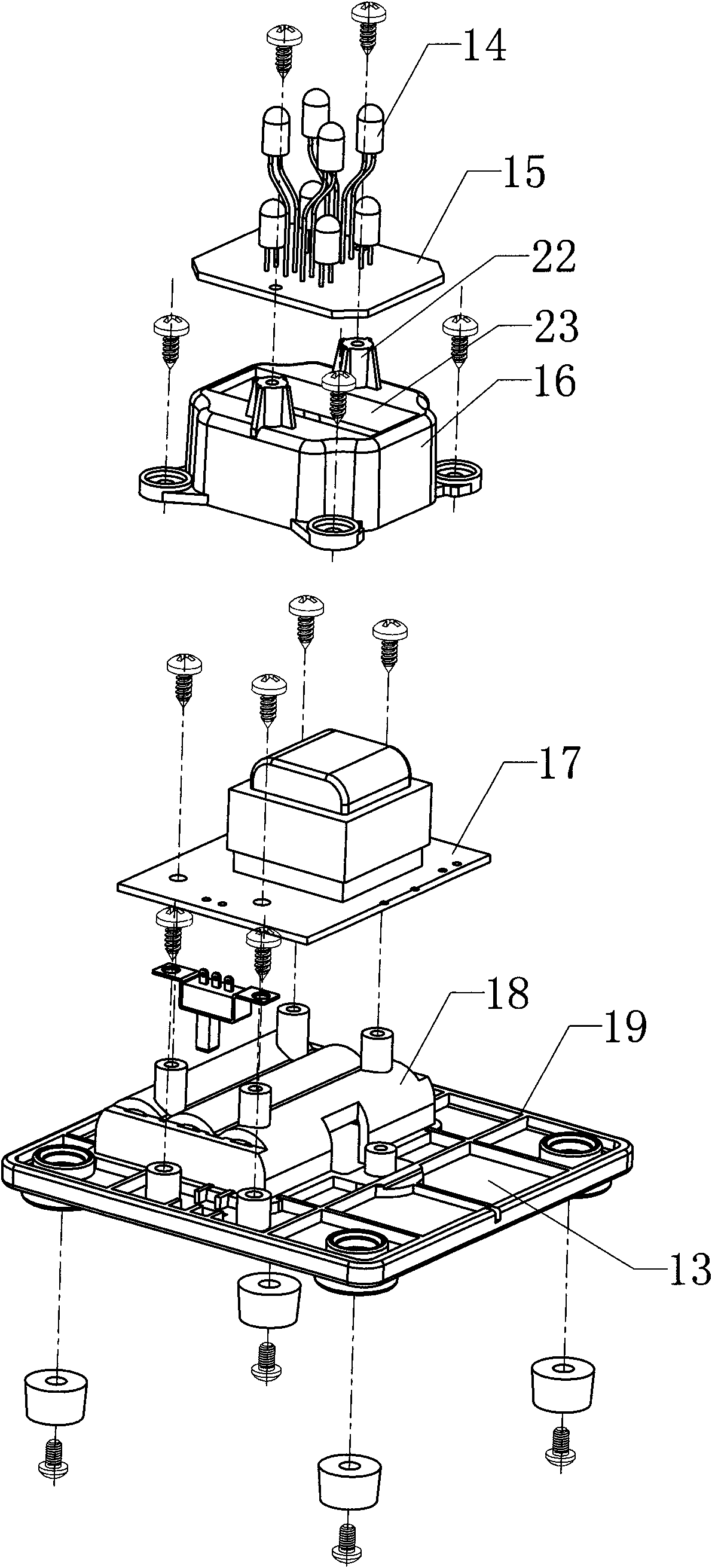

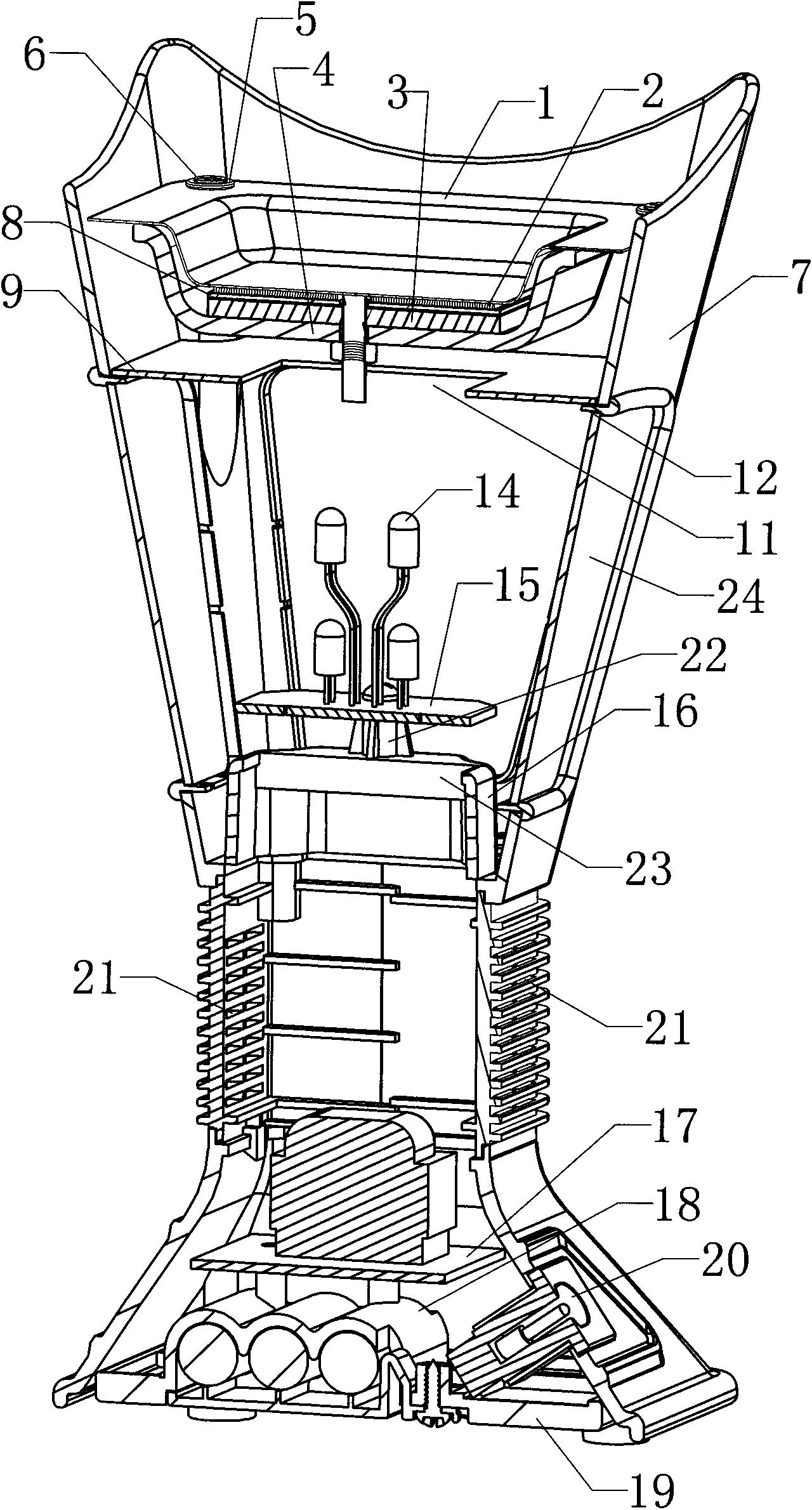

[0016] The electronic incense burner of the present invention includes a furnace body 7, a heating module and a lighting module. The furnace body 7 is provided with a light-transmitting part surrounding the lighting module. The heating module includes a heat conducting plate 1, a heating sheet 2, and a heat insulating layer. 3 and the fixed plate 4, the heat conduction plate 1, the heating sheet 2, the heat insulation layer 3 and the fixed plate 4 are connected sequentially from top to bottom, and the lighting module is located under the fixed plate 4, and it also includes a heat insulating plate 9, the insulating plate The heat plate 9 is located between the fixed plate 4 and the lighting module, and the heat shield 9 is provided with a first ventilation structure for the air in the lighting module to flow to the fixed plate 4, and there is a first venti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com