Novel die bonding material and packaging structure thereof

A new type of solid crystal technology, applied in nanotechnology for materials and surface science, electrical solid devices, semiconductor/solid device components, etc., can solve the problems of production cost reduction, thermal failure, etc., to improve heat dissipation efficiency, The effect of increasing the heat conduction area and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

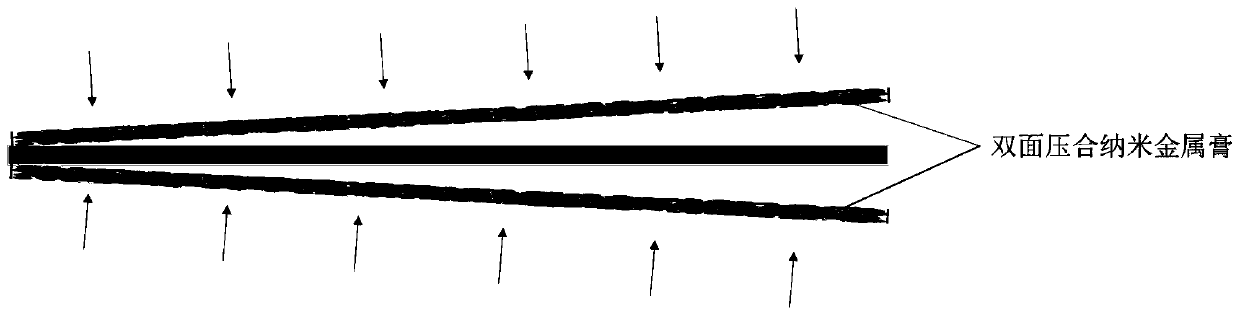

[0026] Embodiment 1 This embodiment provides a novel graphene crystal-bonding material

[0027] Such as Figure 4 As shown, it is a schematic diagram of the new graphene crystal-bonding material, including a Ag@Cu core-shell structure nano-metal paste film with a thickness of 200 μm and a heat dissipation layer with a thickness of 40 μm. The size is 50nm, and the core-shell structure nano-metal particles account for 55.5wt.% of the metal paste film structure; the nano-metal paste film evenly covers the upper and lower surfaces of the heat dissipation layer; the heat dissipation layer is composed of multi-layer graphene; the nano-metal paste film also includes 20.0 wt.% oleic acid oxidizer, and 3.0 wt.% citric acid flux, polyvinylpyrrolidone stabilizer, activator mixture.

[0028] In a preferred embodiment, the Ag@Cu core-shell structure Ag particle size is 50nm, the Cu particle size is 10nm, the core-shell structure nano-metal particles account for 65wt.% of the metal paste f...

Embodiment 2

[0030] Embodiment 2 This embodiment provides a new type of graphene paste crystal-bonding material

[0031] The new graphene paste crystal-bonding material includes a Ni@Cu core-shell structure nano-metal paste film with a thickness of 400 μm and a heat dissipation layer with a thickness of 30 μm. The Ag@Cu core-shell structure Ag particle size is 400 nm, and the Cu particle size is 100 nm. Nano-metal particles with shell structure account for 85.5wt.% of the metal paste film structure; the nano-metal paste film evenly covers the upper and lower surfaces of the heat dissipation layer; the heat dissipation layer is composed of mixed graphene paste, and the nano-metal paste film also includes 10.0wt.% Ethanolamine oxidizer, and 3.0 wt.% lactic acid flux, polyvinylpyrrolidone stabilizer, activator mixture.

[0032] In a preferred embodiment, the Ag@Cu core-shell structure Ag particle size is 50nm, the Cu particle size is 10nm, the core-shell structure nano-metal particles account...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com