Push stabilizing mechanism for forklift

A push-out mechanism and stable technology, applied in the direction of lifting devices, etc., can solve the problems of lack of overall flatness in processing and assembly, more maintenance costs, poor stability, poor adaptability, etc., to improve stability and adaptability, and facilitate Good processing and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

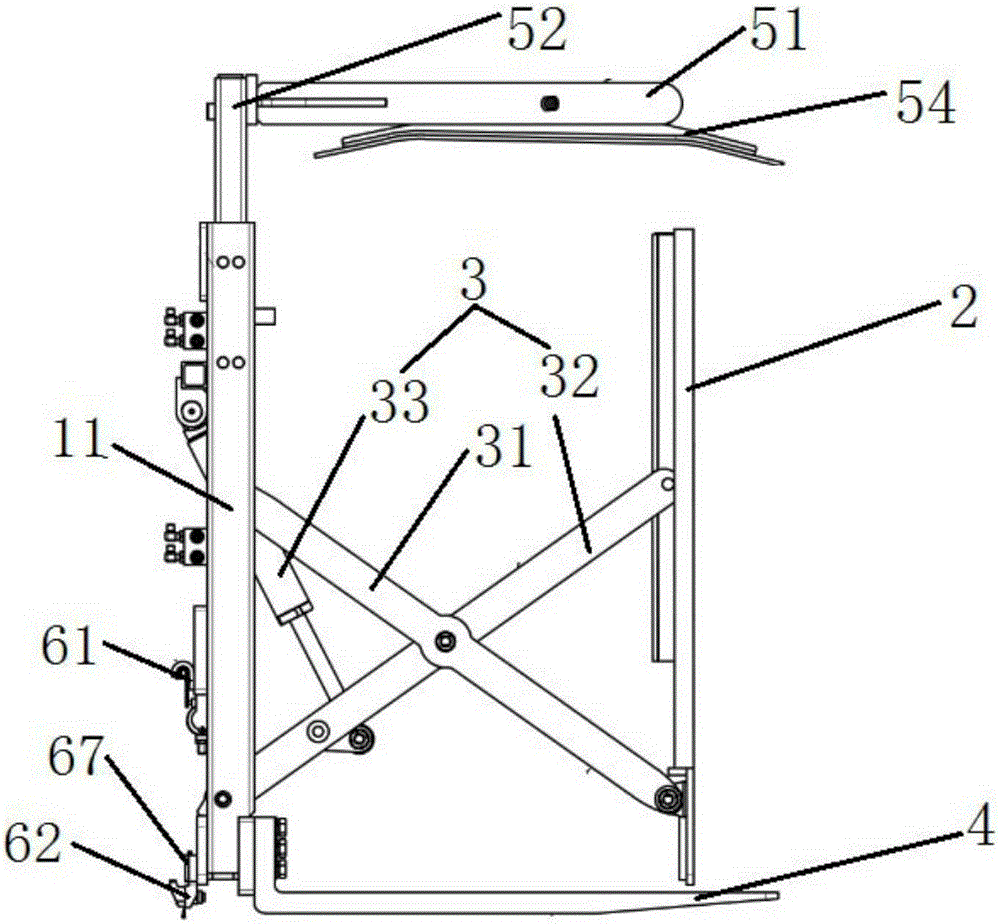

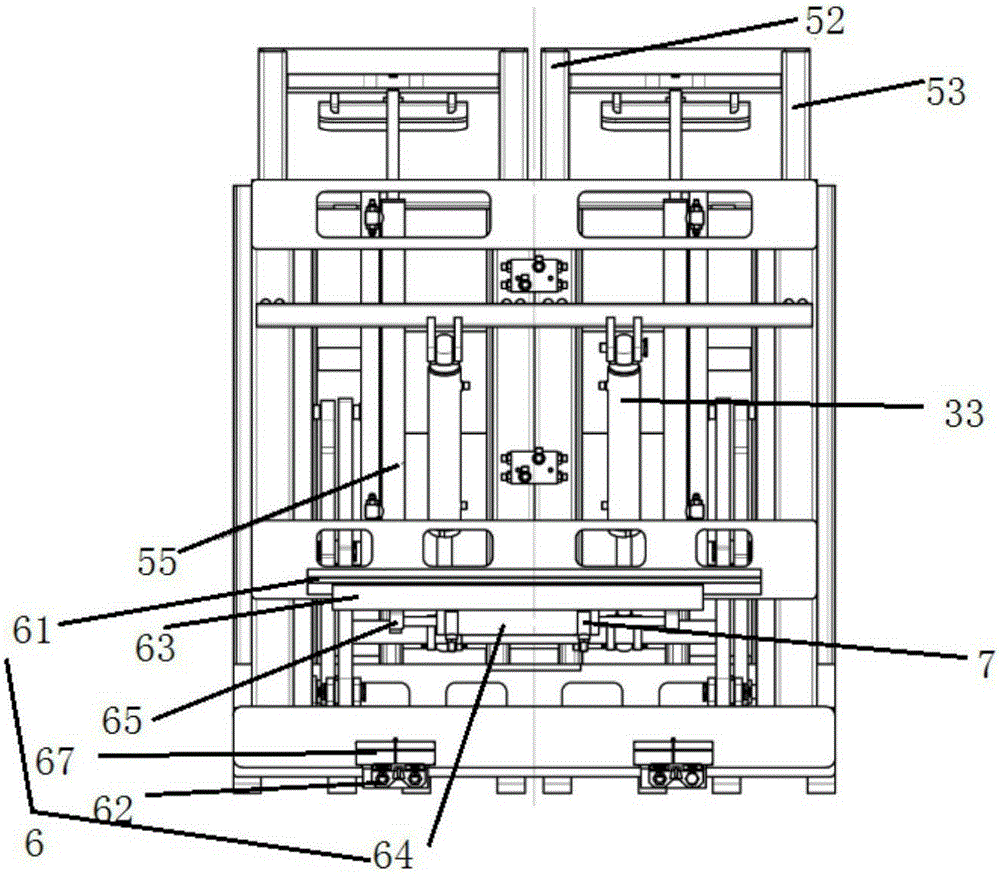

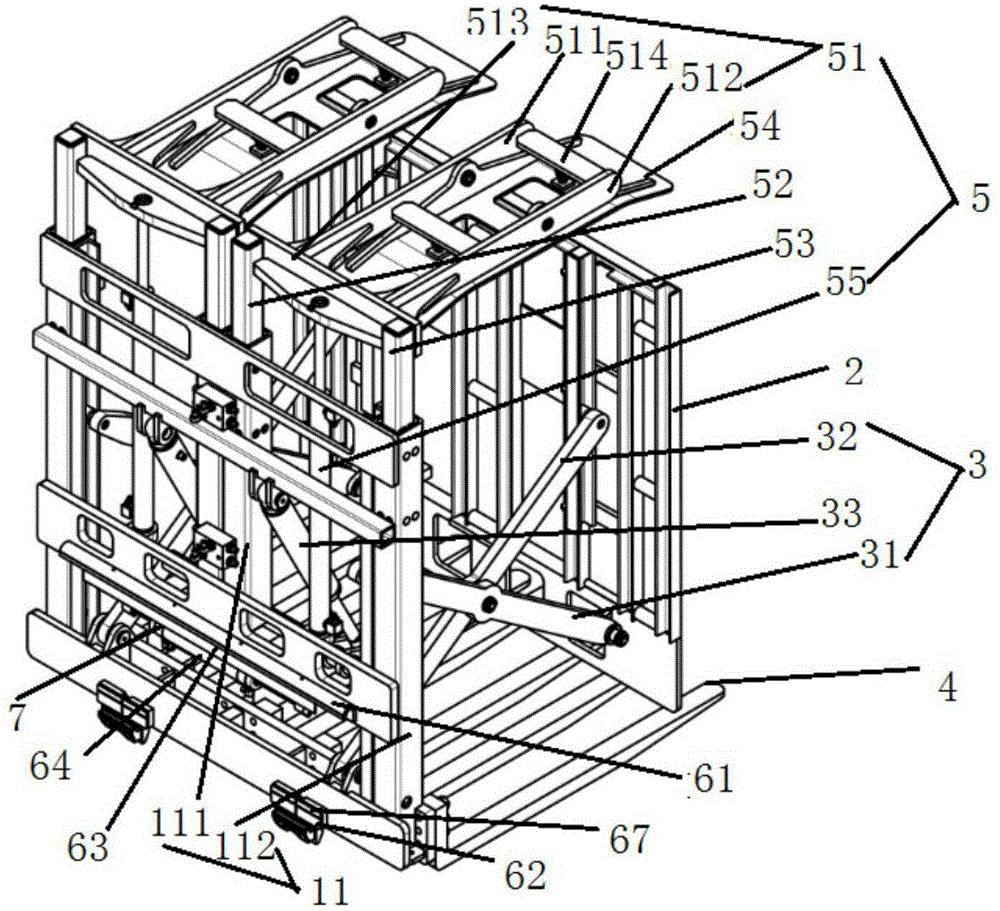

[0023] Such as Figure 1-3 As described above, the push-out stabilizing mechanism for forklifts of the present invention includes a rear bracket assembly, a front push plate assembly 2, a push-out mechanism 3, a cargo fork 4, and several push-down mechanisms 5.

[0024] The push-out mechanism 3 is a scissors-type push-out mechanism, comprising a rear connecting rod 31, a front connecting rod 32, and an ejection cylinder 33; the lower end of the rear connecting rod 31 is hinged with the front push plate assembly 2, and the The higher end of the rear link 31 is hinged with the rear bracket assembly; the lower end of the front link 32 is hinged with the rear bracket assembly, and the higher end of the front link 32 is hinged with the rear bracket assembly. The front push plate assembly is 2 hinges; the intersection of the front connecting rod 32 and the rear connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com