Ejector with flat-tooth pallet fork structure

A technology of ejectors and forks, which is applied in the direction of lifting devices, etc., can solve the problems of processing, assembly, and overall flatness, poor stability, poor adaptability, and small force-bearing surface of forks, so as to improve stability and adaptability , increase the stress area, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

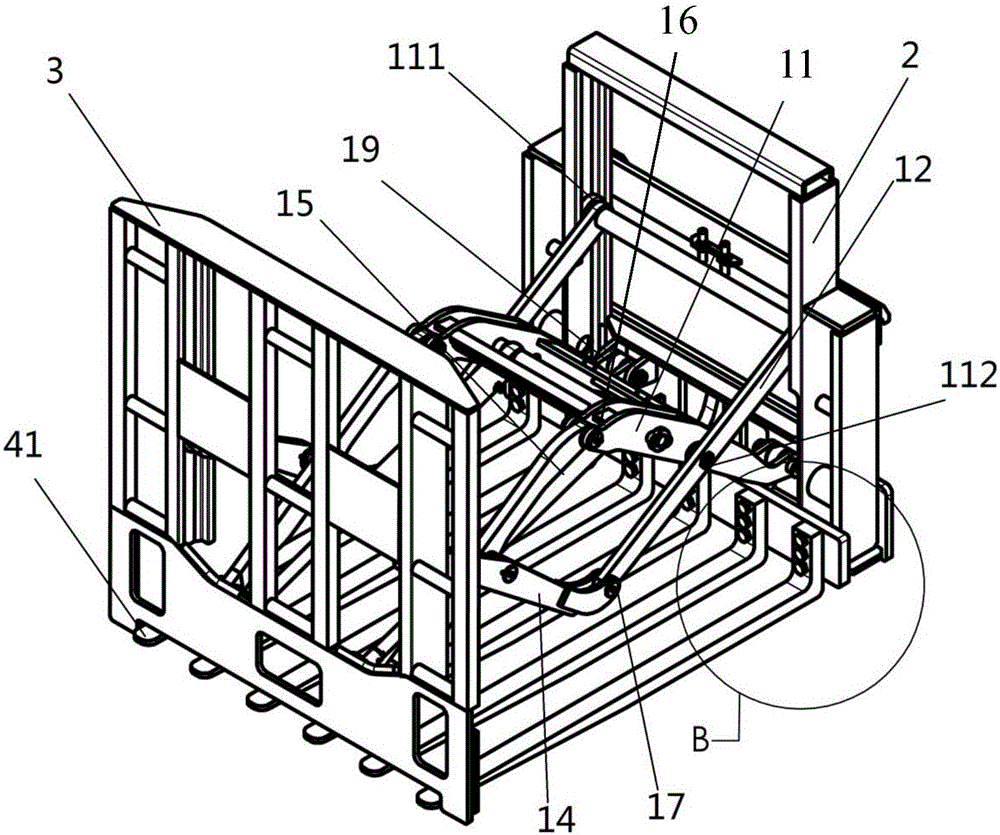

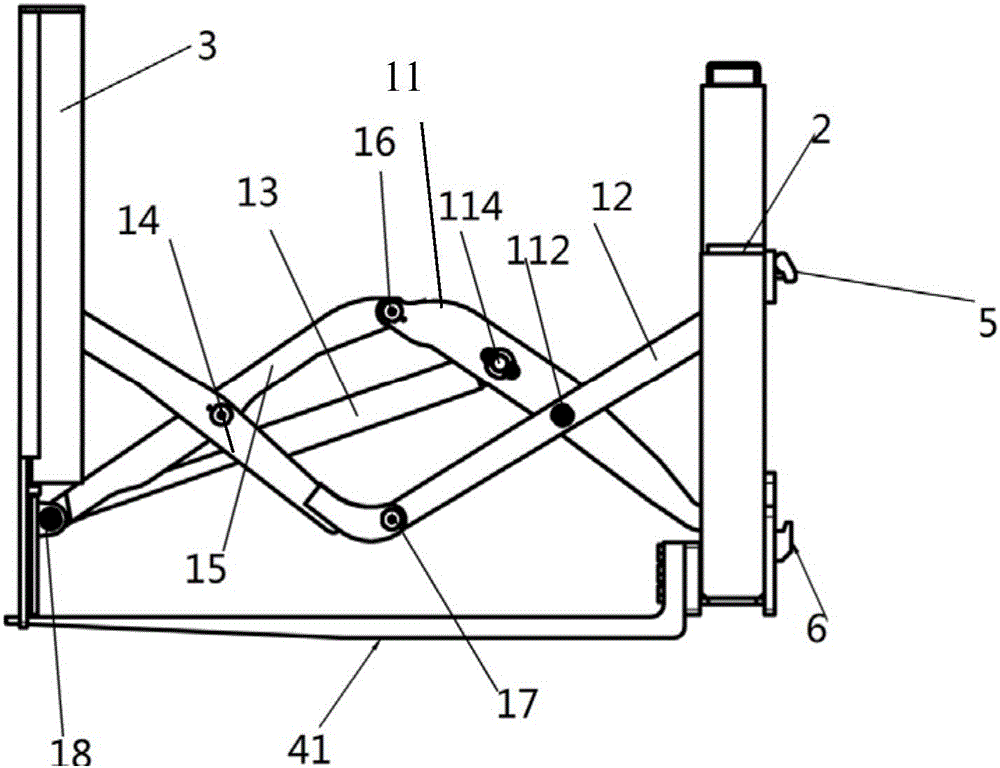

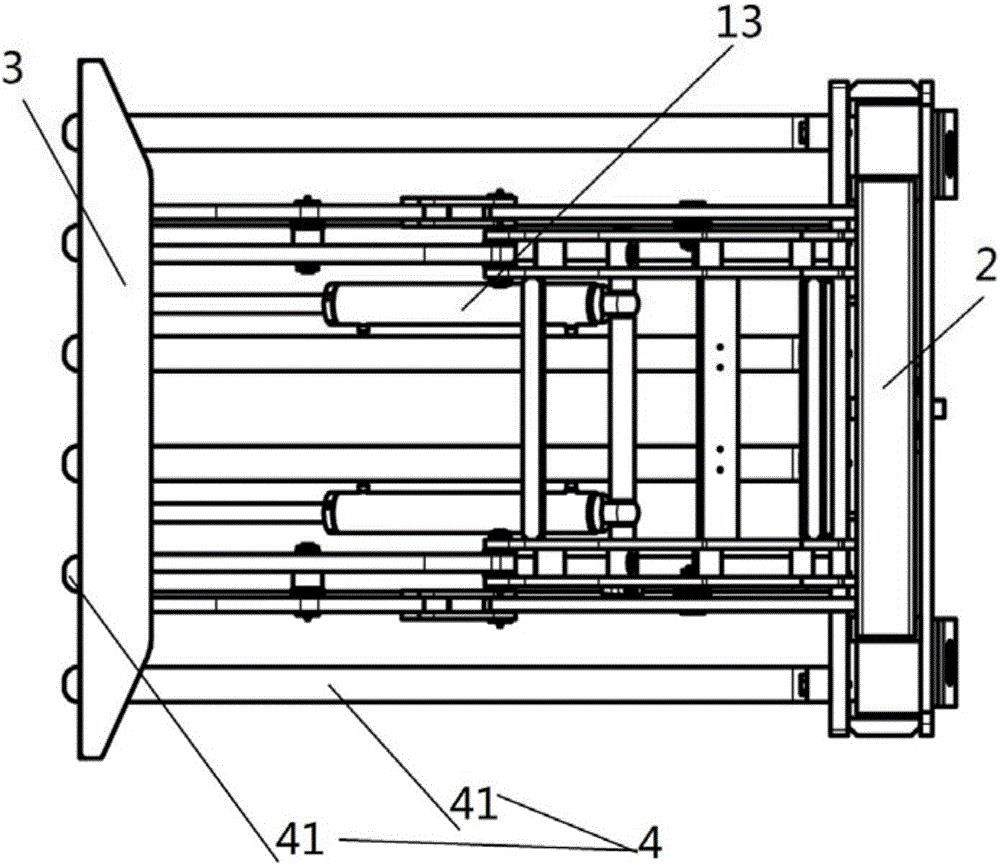

[0016] Such as Figure 1-4 As mentioned above, this embodiment discloses an ejector with a flat-toothed fork structure, including an ejecting mechanism, a rear bracket 2 , a front push frame 3 , a fork 4 , an upper hook 5 and a lower hook 6 .

[0017] Described rear support 2, front pushing frame plate 3 are all existing equipment. One end of the push-out mechanism 1 is hinged with the rear bracket 2 , and the other end of the push-out mechanism is hinged with the front push frame 3 . One end of the fork 4 is connected to the rear bracket 2 through the first bolt 7, the other end of the fork 4 extends to the bottom of the front push frame plate 3, and the fork 4 includes several flat Shaped fork bar 41; the upper hook 5 and the lower hook 6 are respectively arranged at the upper and lower ends of the rear bracket 2.

[0018] The push-out mechanism 1 includes a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com