Slope concrete pouring self-elevating formwork

A concrete and self-lifting technology, applied in the field of concrete pouring, can solve the problems of uneven compaction, difficult control of self-weight settlement of vibration equipment, and reduction of pouring flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

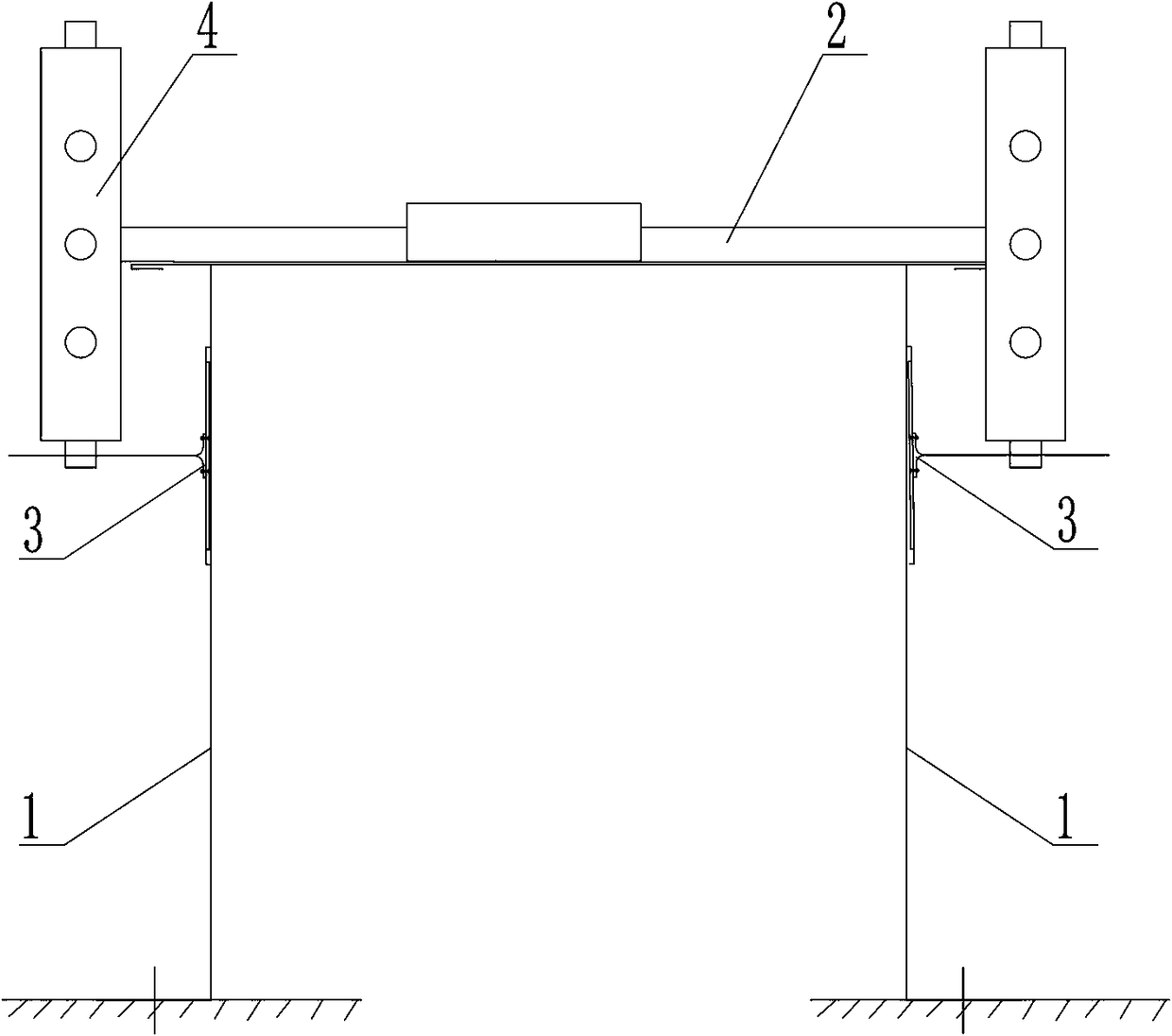

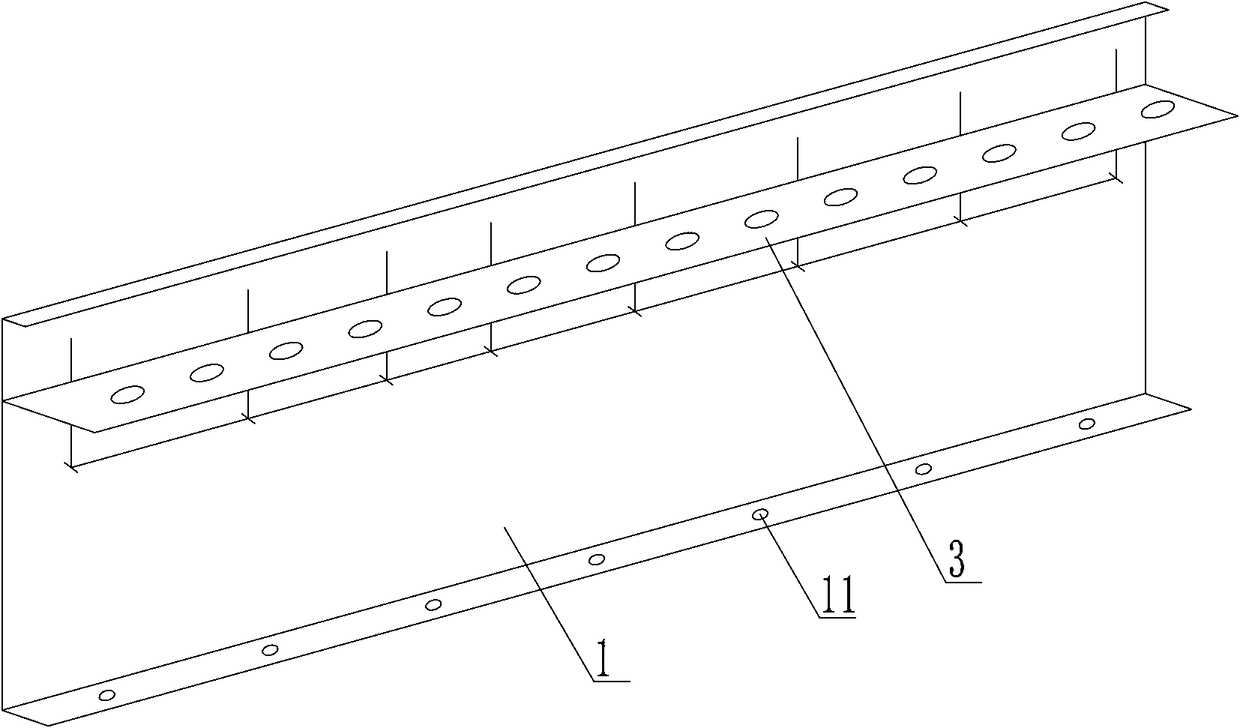

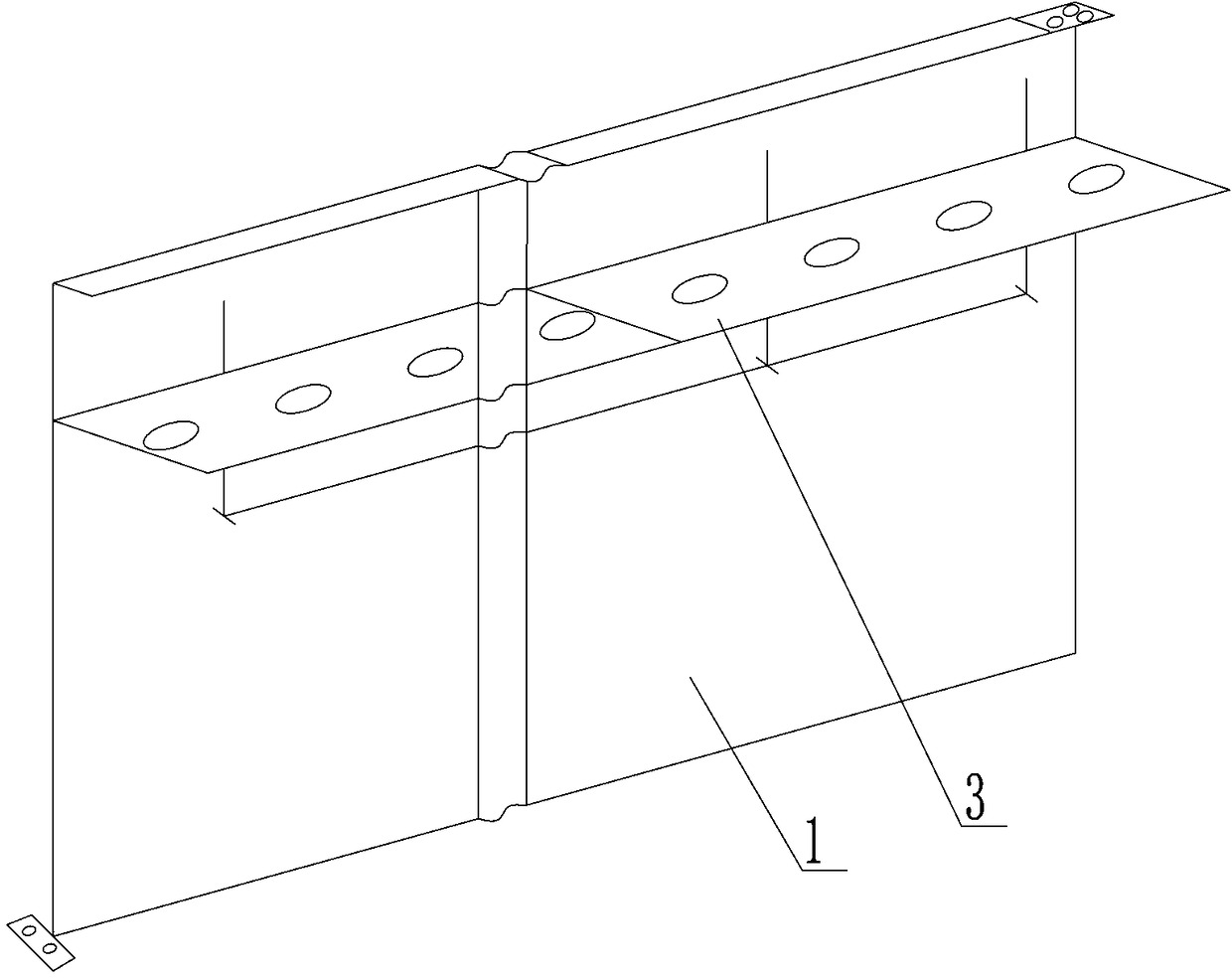

[0042] Such as Figure 1~Figure 6Among them, a self-elevating formwork for concrete pouring on a slope, which includes a side form 1, a top form 2, a track 3, a traveling mechanism 4 and a vibrating mechanism 5; , the track 3 is connected with the side mold 1 and the height is adjustable, the running mechanism 4 is connected with the top mold 2 and cooperates with the track 3, the vibrating mechanism 5 is fixed on the top mold 2, and the running mechanism 4 drives the top mold 2 to move along the track 3. The structure is simple. The side form 1 is fixed on both sides of the concrete pouring slope, the rails 3 are installed on both sides of the side form 1, and the top form 2 is set on the top of the side form 1. The walking mechanism 4 is connected with the top form 2 to cooperate with the track 3. The mechanism 5 is fixed to the top mold 2, the traveling mechanism 4 drives the top mold 2 to lift and level off along the side mold 1, and the vibrating mechanism 5 vibrates and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com