A combined mold and flange manufacturing process

A combined mold and manufacturing process technology, applied in metal rolling and other directions, can solve problems such as low product quality, achieve high production efficiency, improve flatness, and improve dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

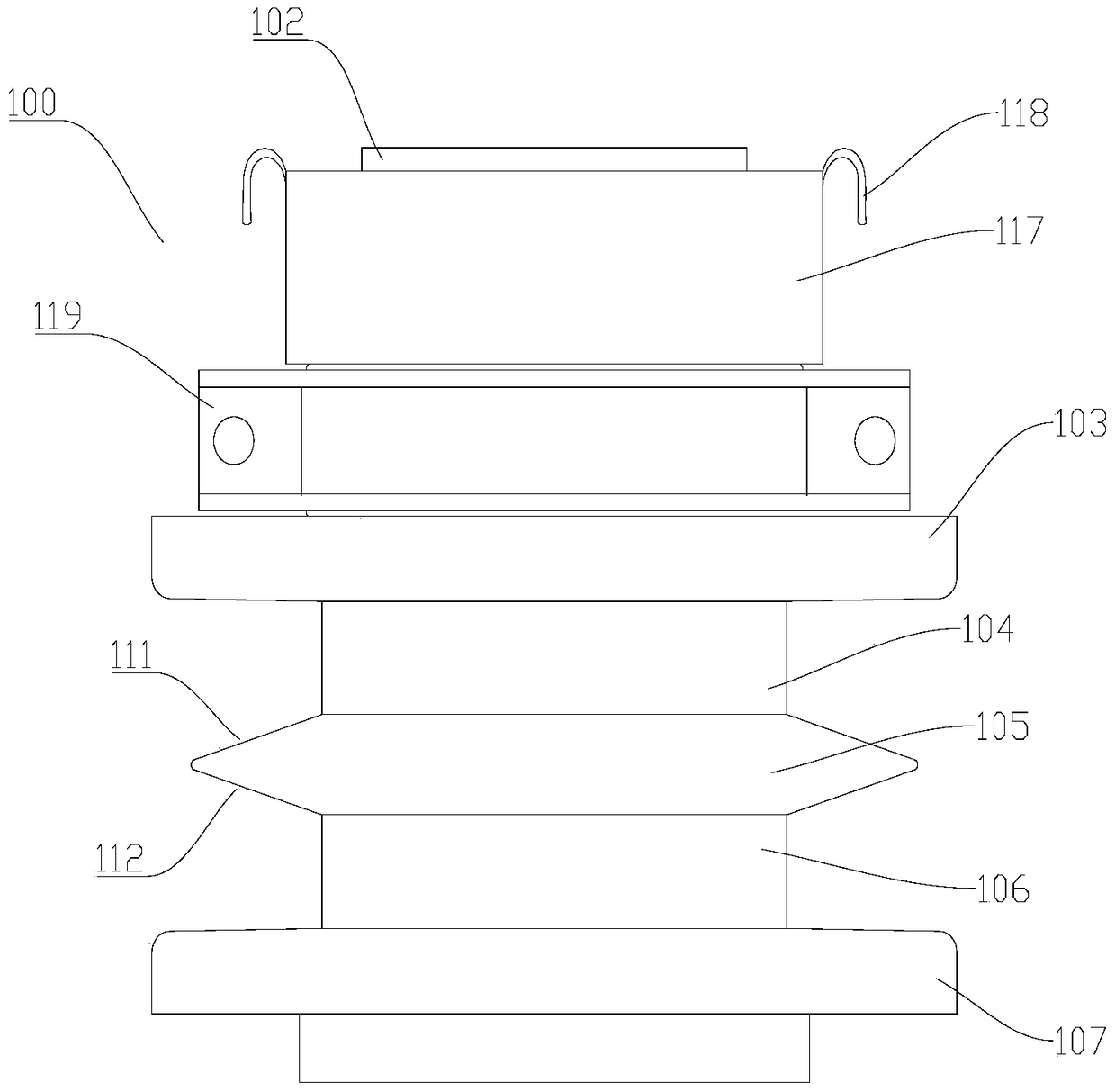

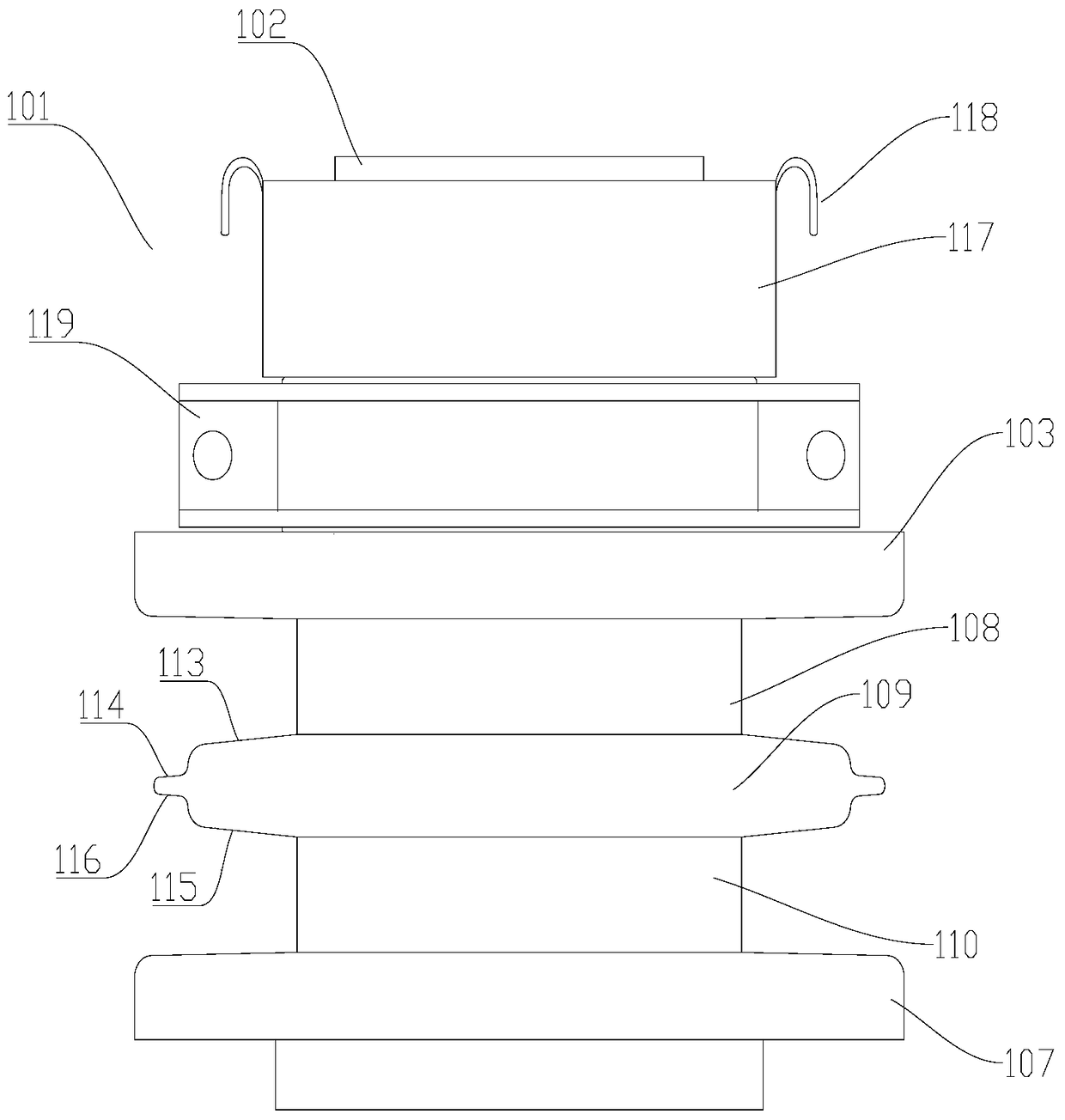

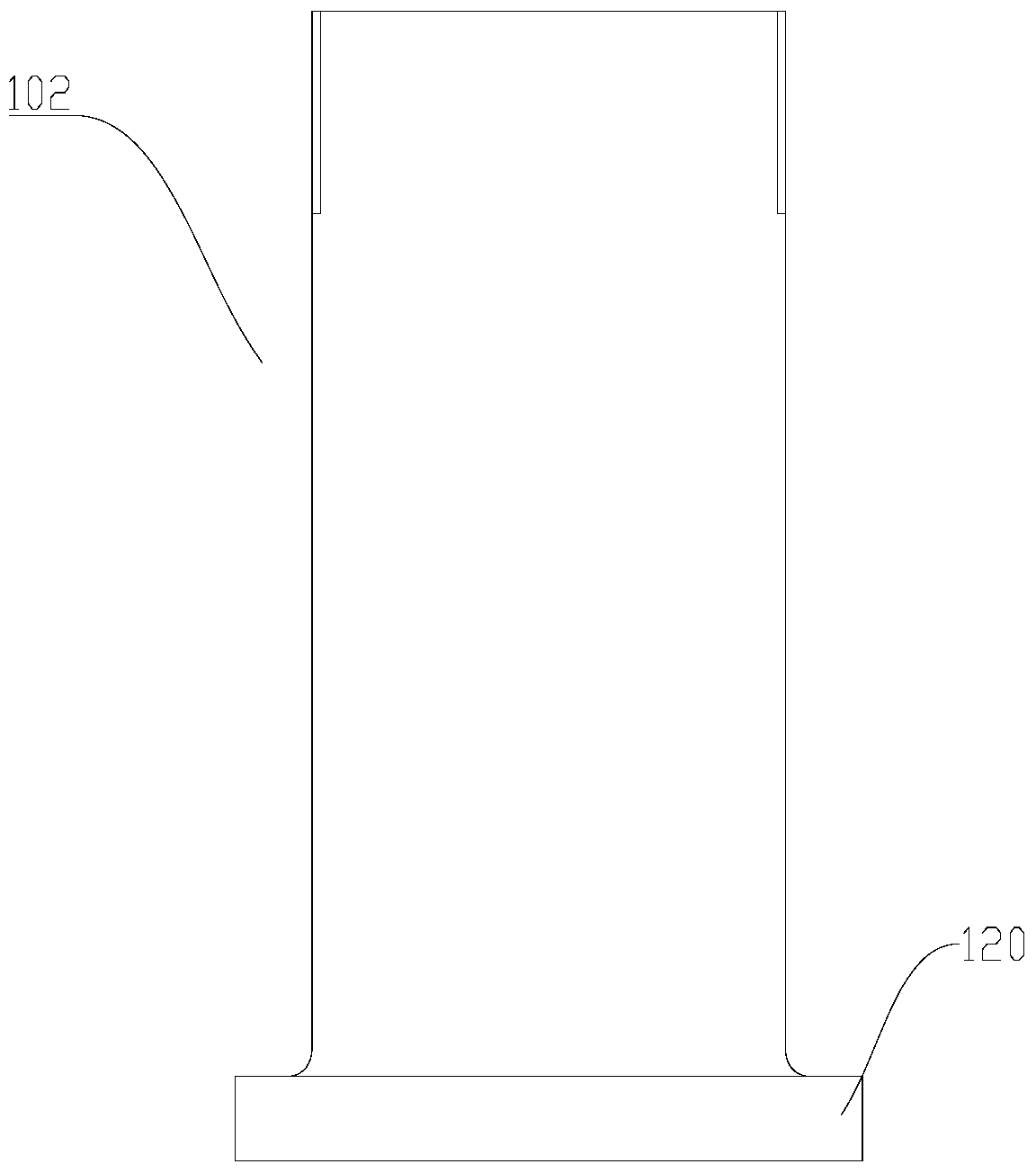

[0047] figure 1 It is a schematic structural view of the preforming mold in the combined mold provided by Embodiment 1 of the present invention, figure 2 It is a schematic structural view of the forming die in the combined die provided in Embodiment 1 of the present invention, image 3 For the structural schematic diagram of the quick-change cylinder in the combined mold provided by Embodiment 1 of the present invention, see Figure 1 to Figure 3As shown, Embodiment 1 of the present invention provides a combined mold, including: a preforming mold 100, which is used to carry out radial preforming rolling on the inner wall of the ring flange blank by using a half-open and half-closed hole type; a forming mold 101, It is used for radial forming rolling of the inner wall of the ring flange blank with a half-open and half-closed pass. The pre-forming mold includes: a quick-change cylinder 102, and the quick-change cylinder 102 is sequentially provided with an upper baffle 103, a...

Embodiment 2

[0055] Figure 4 The flow chart of the flange manufacturing process provided by Embodiment 2 of the present invention, Figure 5 It is a schematic diagram of the structure of the ring rolling machine without a combined mold in the flange manufacturing process provided by Embodiment 2 of the present invention, Image 6 A schematic structural view of the mandrel of the ring rolling machine in which the preforming die is set in the flange manufacturing process provided by Embodiment 2 of the present invention, Figure 7 A structural schematic diagram of radial preforming rolling in the flange manufacturing process provided by Embodiment 2 of the present invention, Figure 8 For the structural diagram of radial forming rolling in the flange manufacturing process provided by Embodiment 2 of the present invention, see Figure 4 to Figure 8 As shown, the second embodiment discloses a flange manufacturing process, which includes the following steps:

[0056] Step S300, taking the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com