Linear quartz crystal resonator adhesive dispensing mechanism and operation method

A quartz crystal and resonator technology, applied in the field of linear quartz crystal resonator dispensing structure, can solve the problems of difficult control of flatness and high platform flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

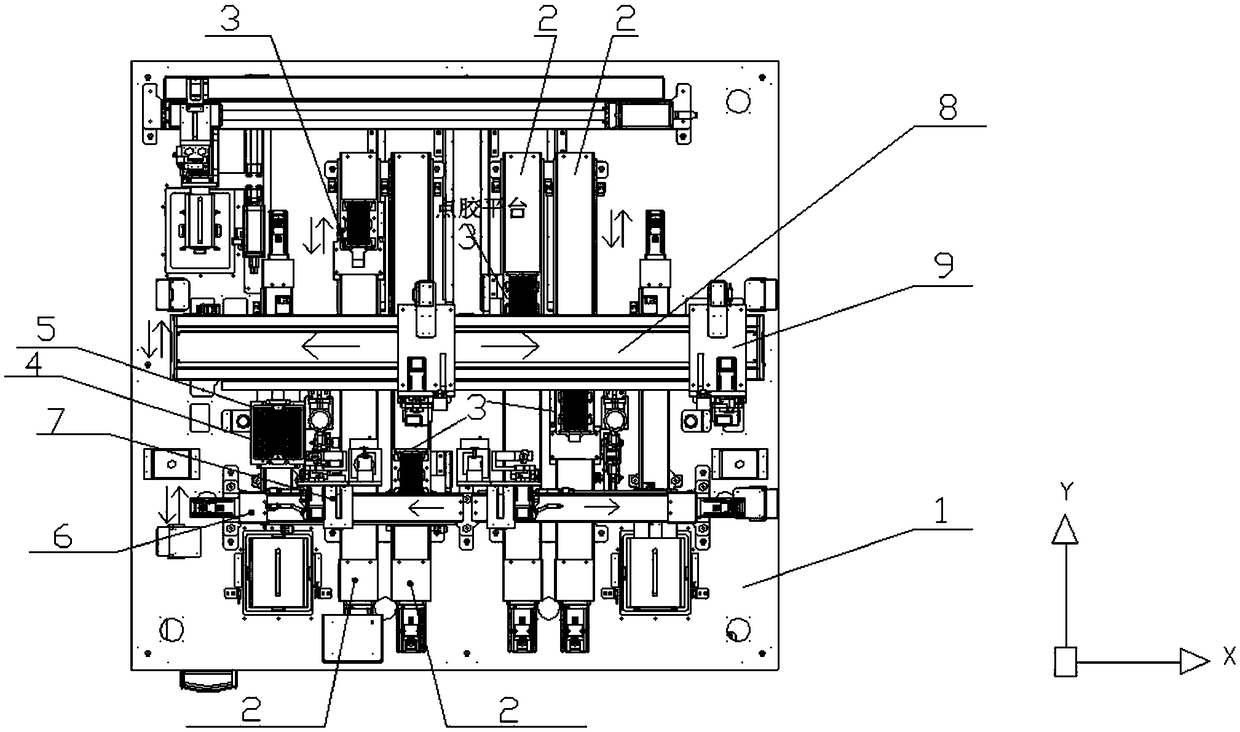

[0026] refer to figure 1 , a linear quartz crystal resonator dispensing structure and operation method, including a frame 1 and a dispensing platform linear motion axis 22 arranged on the frame 1, a dispensing platform linear motion axis 22 is provided with a dispensing platform 3 , one side of the linear motion axis 22 of the dispensing platform is provided with a dispensing tray 4, the dispensing tray 4 is provided with a quartz crystal resonator base 5, and the dispensing platform linear movement axis 22 is provided with a dispensing platform linear motion The dispensing head movement shaft 66 perpendicular to the axis 22 is provided with a dispensing head 7 on the dispensing head movement shaft 66, and a transfer shaft 8 parallel to the dispensing head movement shaft 66 is arranged above the dispensing head movement shaft 66, and the transfer A tray transfer mechanism 9 is provided on the shaft 8 .

[0027] This product reduces the processing accuracy requirements of the ...

Embodiment 2

[0035] The linear quartz crystal resonator dispensing structure includes the following operating steps:

[0036] S1, first transfer the quartz crystal resonator base 5 from the incoming material tray to the special quartz crystal resonator dispensing tray 4;

[0037] S2. Place the prepared quartz crystal resonator dispensing tray 4 on the dispensing platform 3 through the tray transfer mechanism 9;

[0038] S2. In the above S1 step, control the negative pressure device of the dispensing platform 3 to absorb all the quartz crystal resonator bases 5 in the dispensing tray 4 to achieve stable positioning.

[0039] It works as follows:

[0040] This product reduces the processing accuracy requirements of the working platform by changing the movement mode and bearing mode of the base 5 of the quartz crystal resonator, and provides technical guarantee for the processing operation of a large number of quartz crystal resonators on the same platform. The difference between this type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com