Underground cast-in-place concrete structure outer wall neck construction method

A technology of concrete structure and construction method, applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve the problem that the formwork process is difficult to meet the design requirements, and achieve the effect of controllable flatness and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

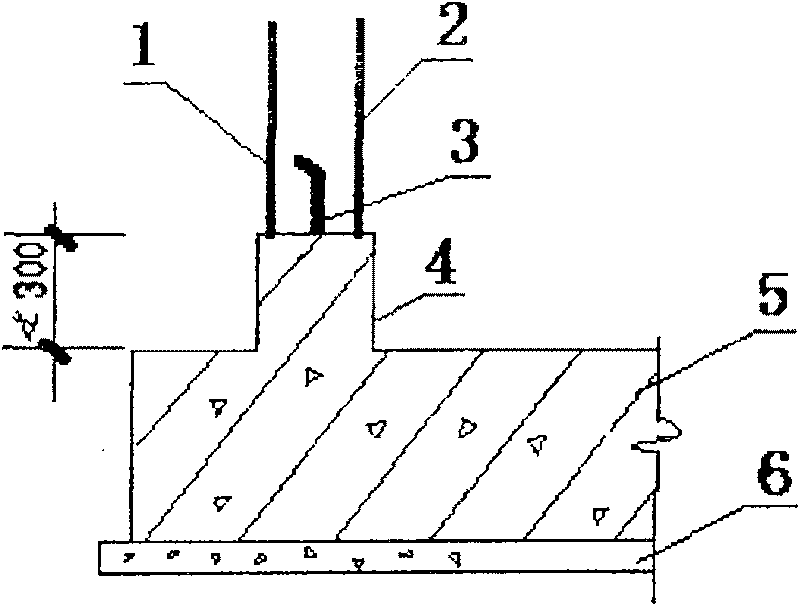

[0017] figure 1 Shown is a schematic diagram of the base plate and the neck of the outer wall poured by the existing method, in the figure: the outer reinforcement of the wall 1; the inner reinforcement of the wall 2; the waterproof steel plate 3; the neck of the outer wall 4; the foundation base 5;

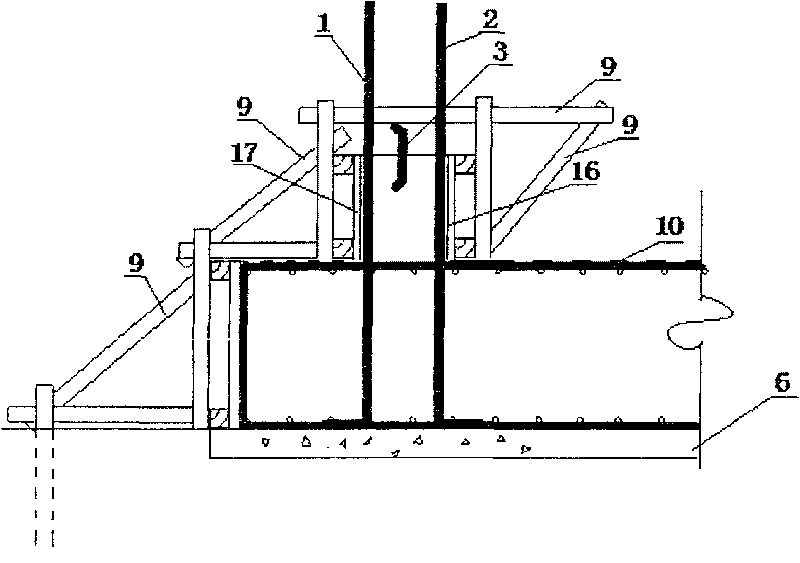

[0018] In order to make the base plate of the underground foundation and the neck of the wall form at one time, the prior art adopts the method of lifting the formwork and supporting the formwork, see figure 2 , among the figure: basic reinforcing bar 10, scaffold pipe 9, first inner formwork 16, the first outer formwork 17, inner and outer formwork is made up of multi-layer board, square wood.

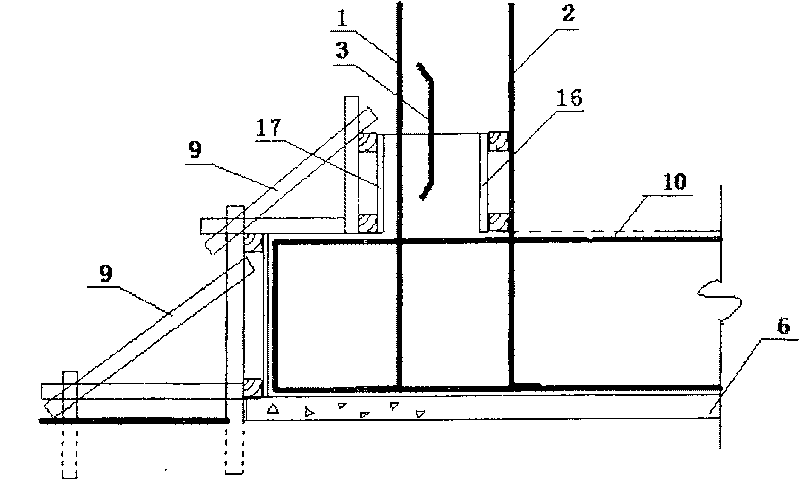

[0019] A kind of underground cast-in-place concrete structure external wall neck construction method of the present invention comprises the following steps: (see image 3 )

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com