Coaxial connector

A technology for coaxial connectors and butt connectors, which is applied in connection, two-part connection devices, welding/welding connections, etc., can solve the problems of easy disengagement, low production efficiency, and easy tinning, etc., so as to eliminate buckling failure The effect of tightness and flatness is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

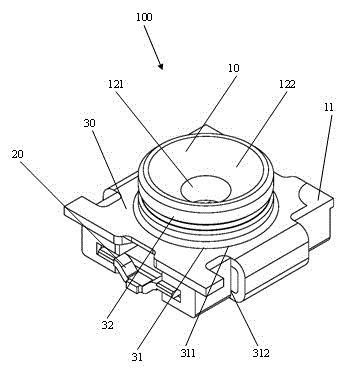

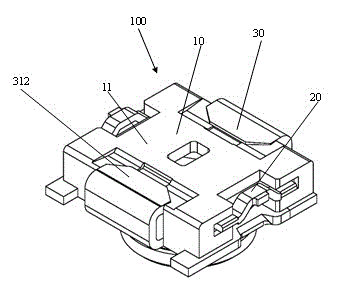

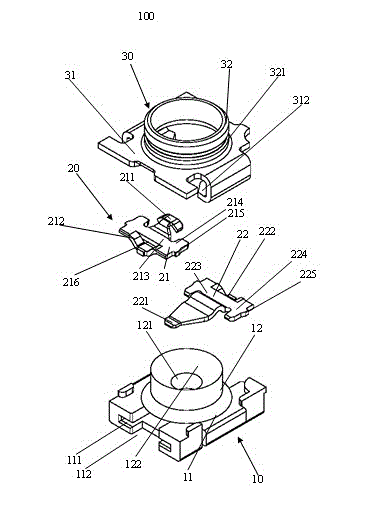

[0018] Please refer to Figure 1-4 As shown, the coaxial connector 100 of the present invention includes an insulating body 10, a conductive terminal 20 installed on the insulating body 10, and a metal shell 30 arranged outside the insulating body 10, and the insulating body 10 is injection-molded on the metal Inside the housing 30. The coaxial connector 100 can be surface soldered to an external circuit board (not shown).

[0019] Please refer to Figure 1-4 As shown, the insulating body 10 is formed with a flat base 11 and a docking portion 12 vertically extending from the base 11 to one side, and the docking portion 12 is provided with a receiving portion 121 for inserting a docking connector (not shown). . The receiving portion 121 is cylindrical. The free end of the docking part 12 is provided with a guide part 122 whose diameter is larger than that of the receiving part 121. The shape of the guiding portion 122 is bell-shaped, so that when the butting connector is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com