Laser height pole device capable of controlling flatness of masonry

A technology of flatness and pictograph, which is applied in the field of laser pictograph devices, can solve the problems of affecting construction progress, construction inconvenience, and low construction efficiency, and achieve the effects of ensuring measurement accuracy, reducing measurement errors, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

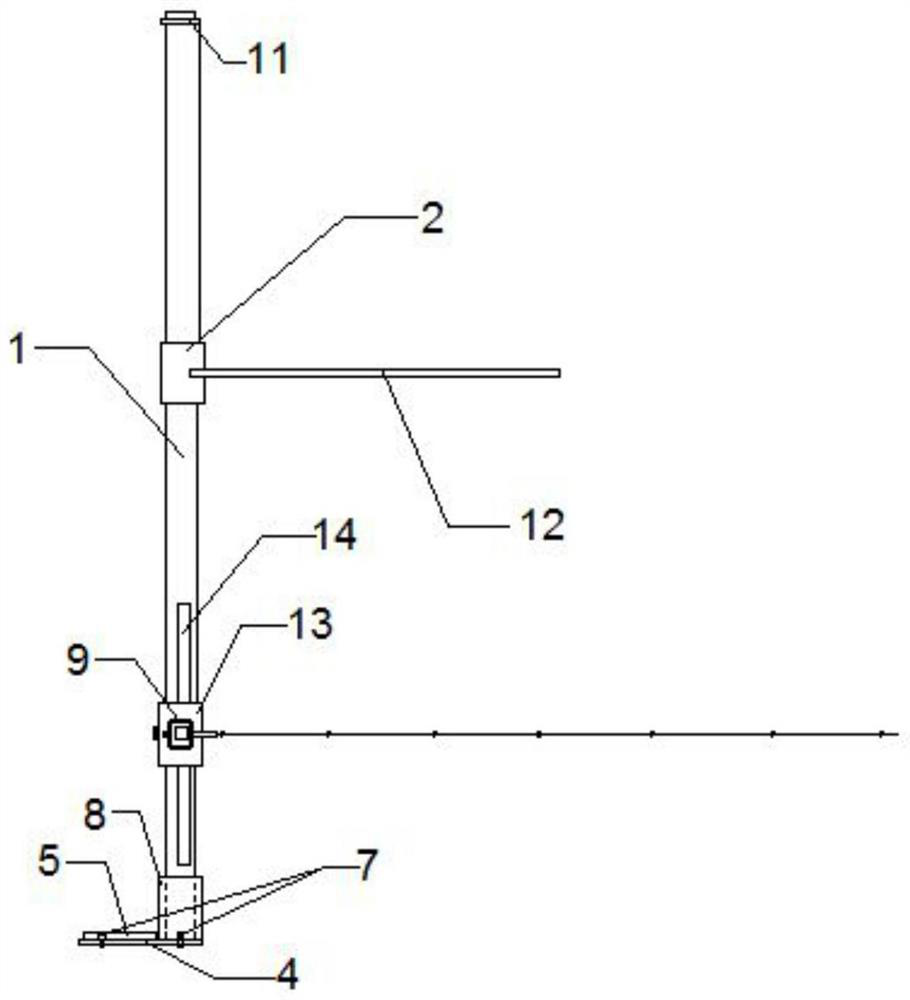

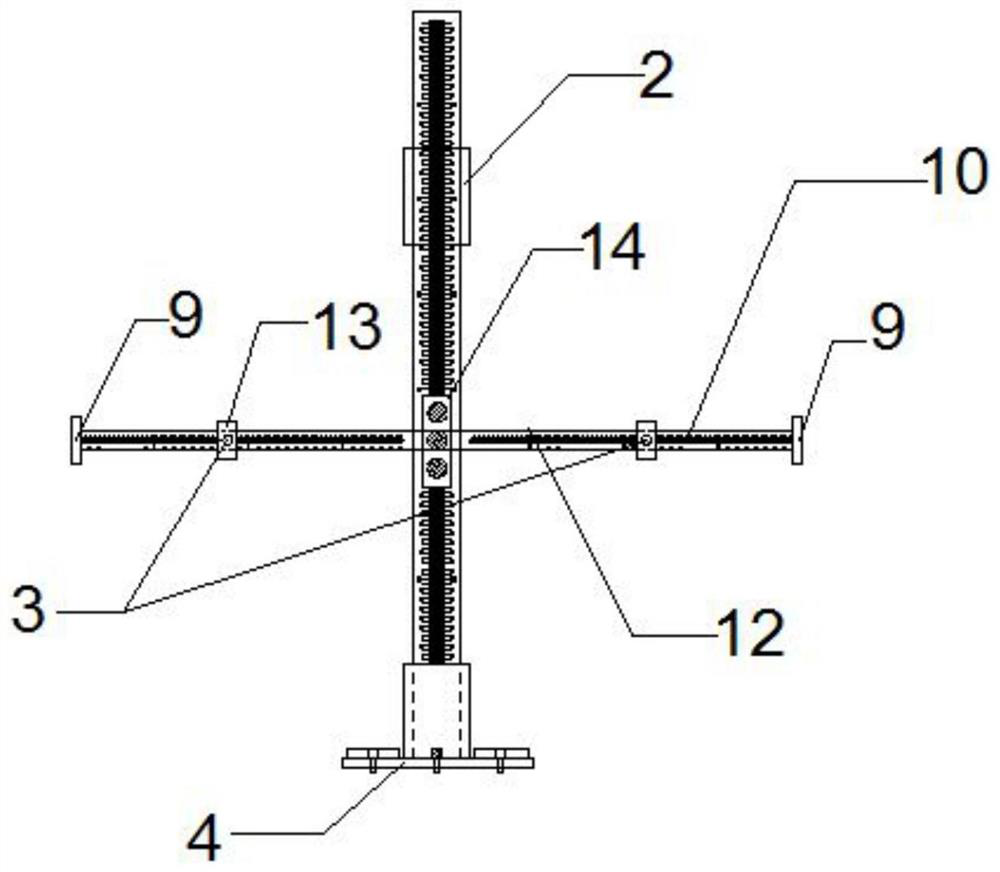

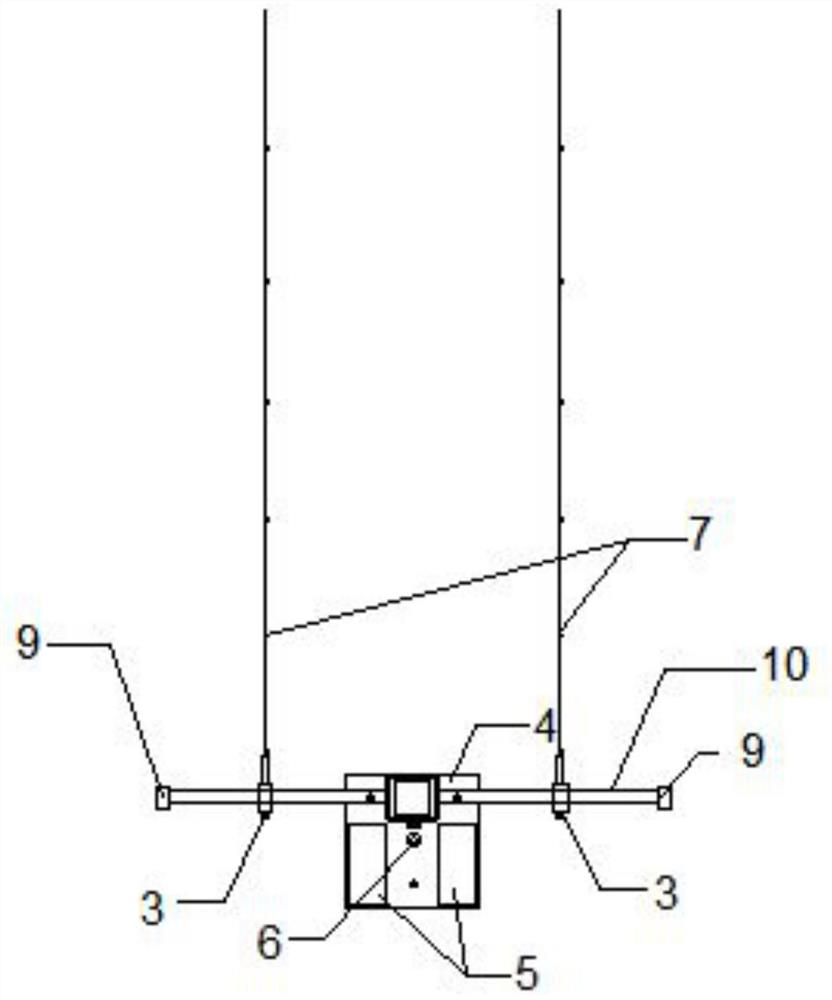

[0033] Such as Figure 1-4 As shown: a kind of scale rod device that can control the flatness of masonry includes a leveling base 4, a vertical rod 1 is fixedly connected to the leveling base 4, a horizontal rod 10 is fixedly connected to the vertical rod 1, and the horizontal rod 10 is connected to the vertical rod 1. Bars 1 are perpendicular to each other;

[0034] A first sleeve 2 is movably connected to the pole 1, the first sleeve 2 is located above the cross bar, and a longitudinal measuring rod 12 is fixedly connected to the first sleeve 2, and the longitudinal measuring rod 12 is perpendicular to the vertical pole 1;

[0035] A second sleeve 13 is movably connected to the cross bar 10, and there are two second sleeves 13, and a laser emitter 3 is mounted on the second sleeve 13.

[0036] Vertical bar 1, cross bar 10 and longitudinal measuring bar 12 are all scale rods, and vertical bar 1, cross bar 10 and longitudinal measuring bar 12 are telescopic bars.

[0037] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com