Device and method for trenchless replacement of underground pipe

a technology for underground pipes and devices, applied in the direction of tube shearing machines, manufacturing tools, borehole/well accessories, etc., can solve the problems of heavy equipment, high price, and limited use of prior art trenchless technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

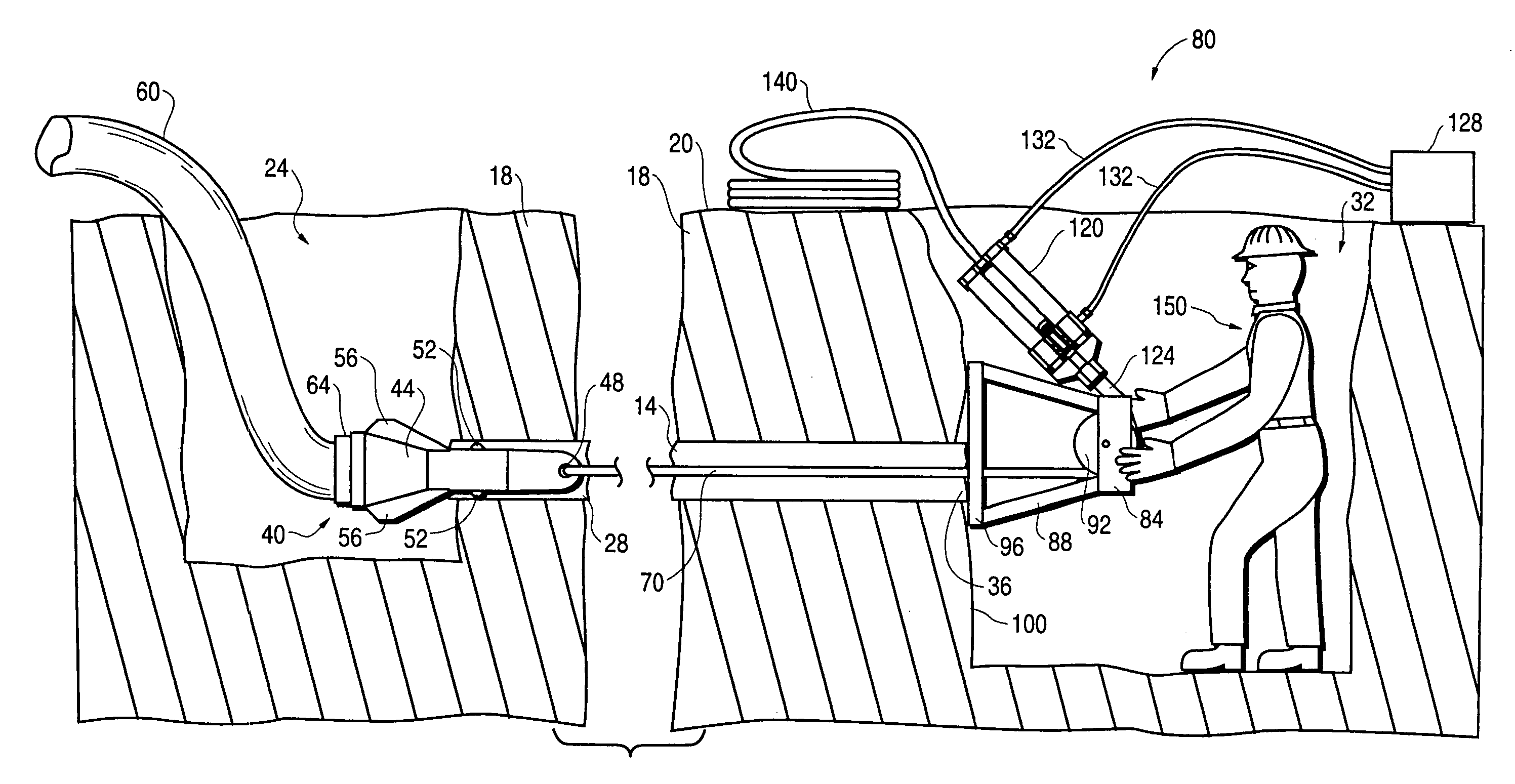

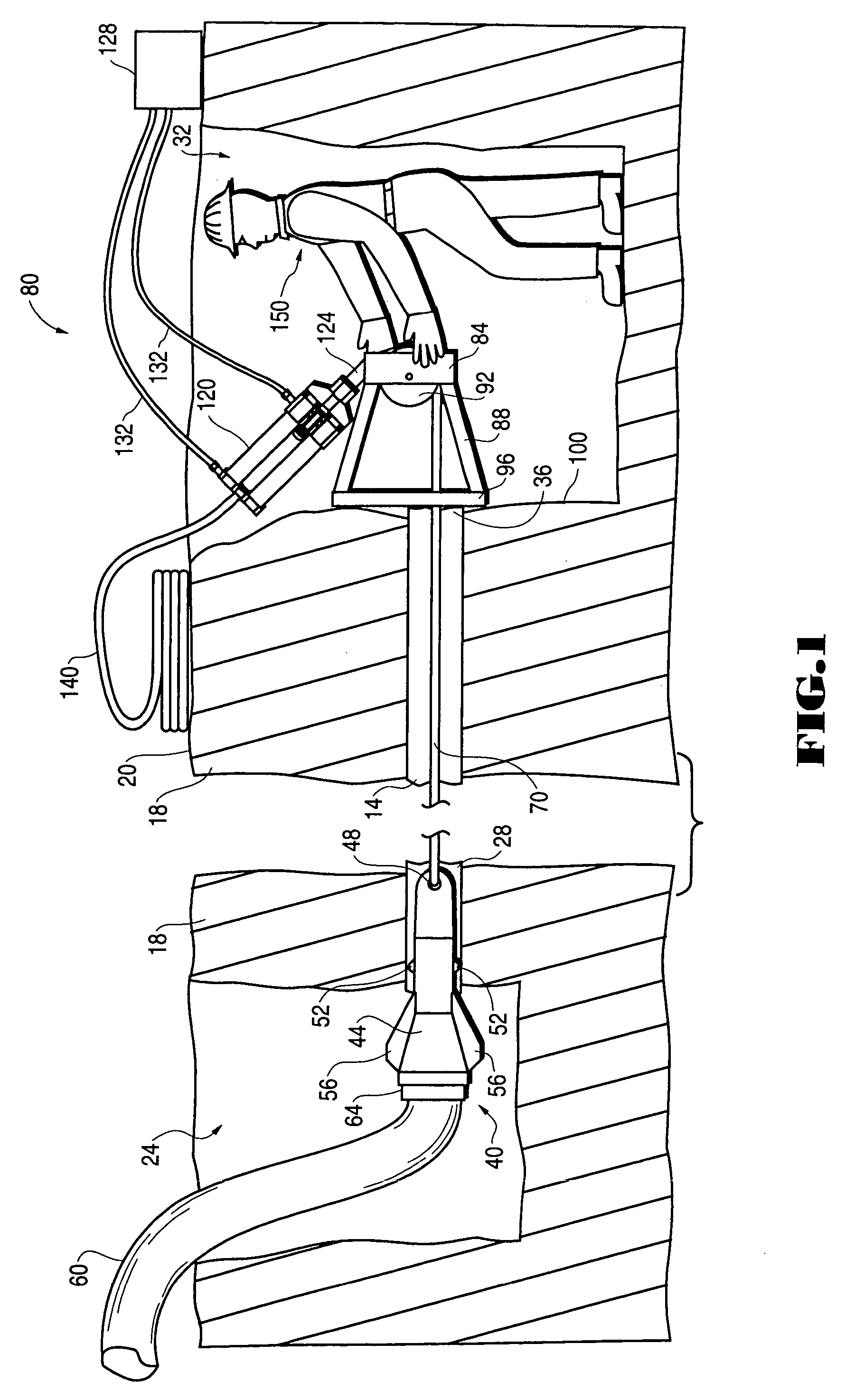

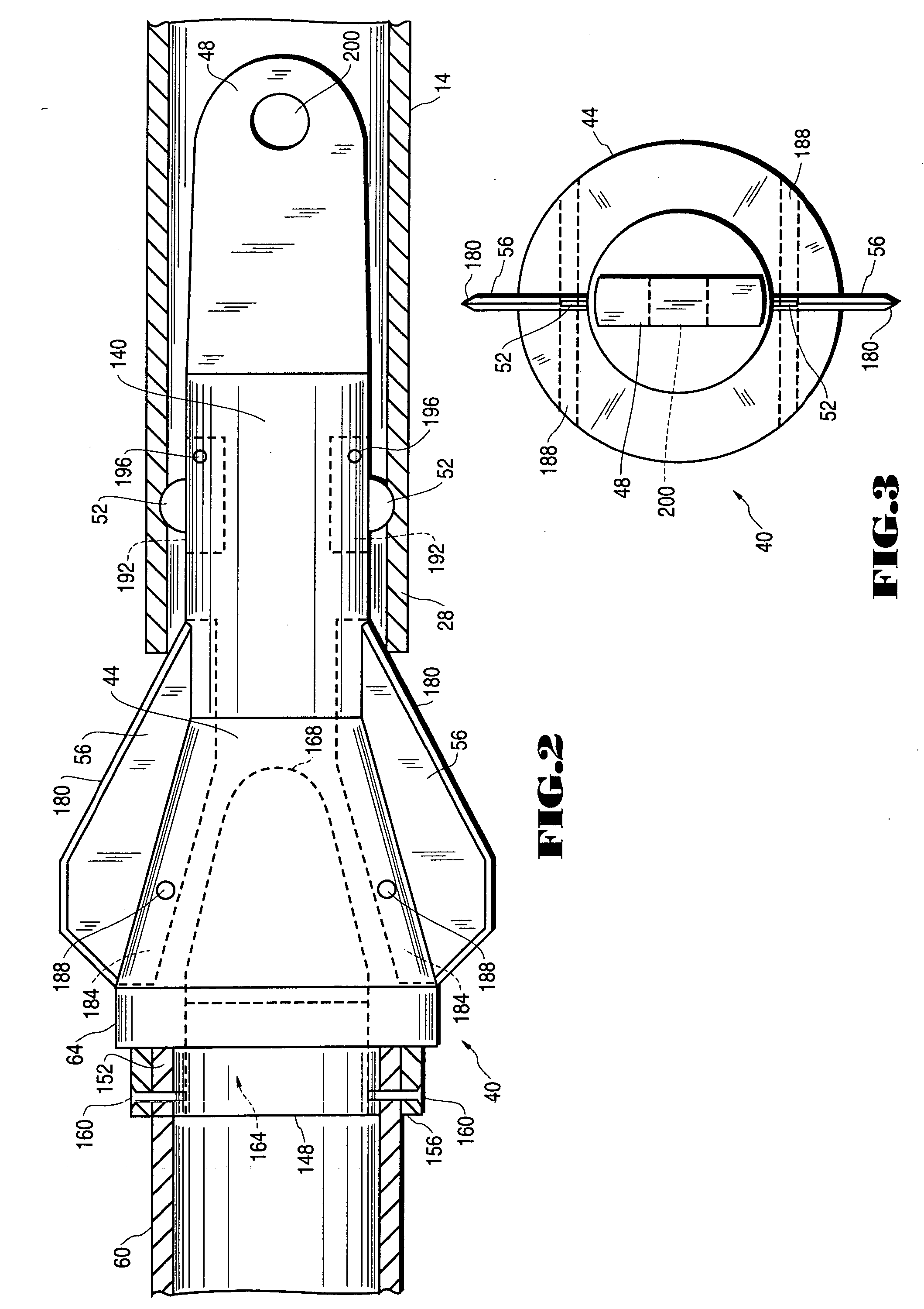

[0046]FIG. 1 is a side elevational view depicting the use of the trenchless pipe replacement device of the present invention. As depicted therein, an existing pipe 14 that is being replaced is disposed within earth 18 beneath the ground level surface 20. A first hole 24 has been dug to reveal a first end 28 of the pipe 14, and a second hole 32 has been dug to reveal a second end 36 of the pipe 14. A pipe parting and expanding device 40 referred to herein as a mole, is inserted within the first pipe end 28. The mole 40 includes a generally tapered body portion 44, a nose portion 48, one or more pipe scoring wheels 52 and one or more pipe parting fins or blades 56 disposed along the body portion 44. A length of replacement pipe 60 is removably engaged to the rearward end 64 of the body portion 44 of the mole 40. A detailed description of the mole 40 is presented herebelow.

[0047] A mole pulling cable 70 is passed from the second end of the pipe 36, through the pipe 14 to a pinned enga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com