Mechanized slot drilling

a slot drilling and slot technology, applied in the direction of shaft sinking, shaft equipment, borehole/well accessories, etc., can solve the problem of limited net energy that can be transmitted to the cutting formation, and achieve the effect of maximizing rotation, enhancing or replacing, and rapid creation of slot volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

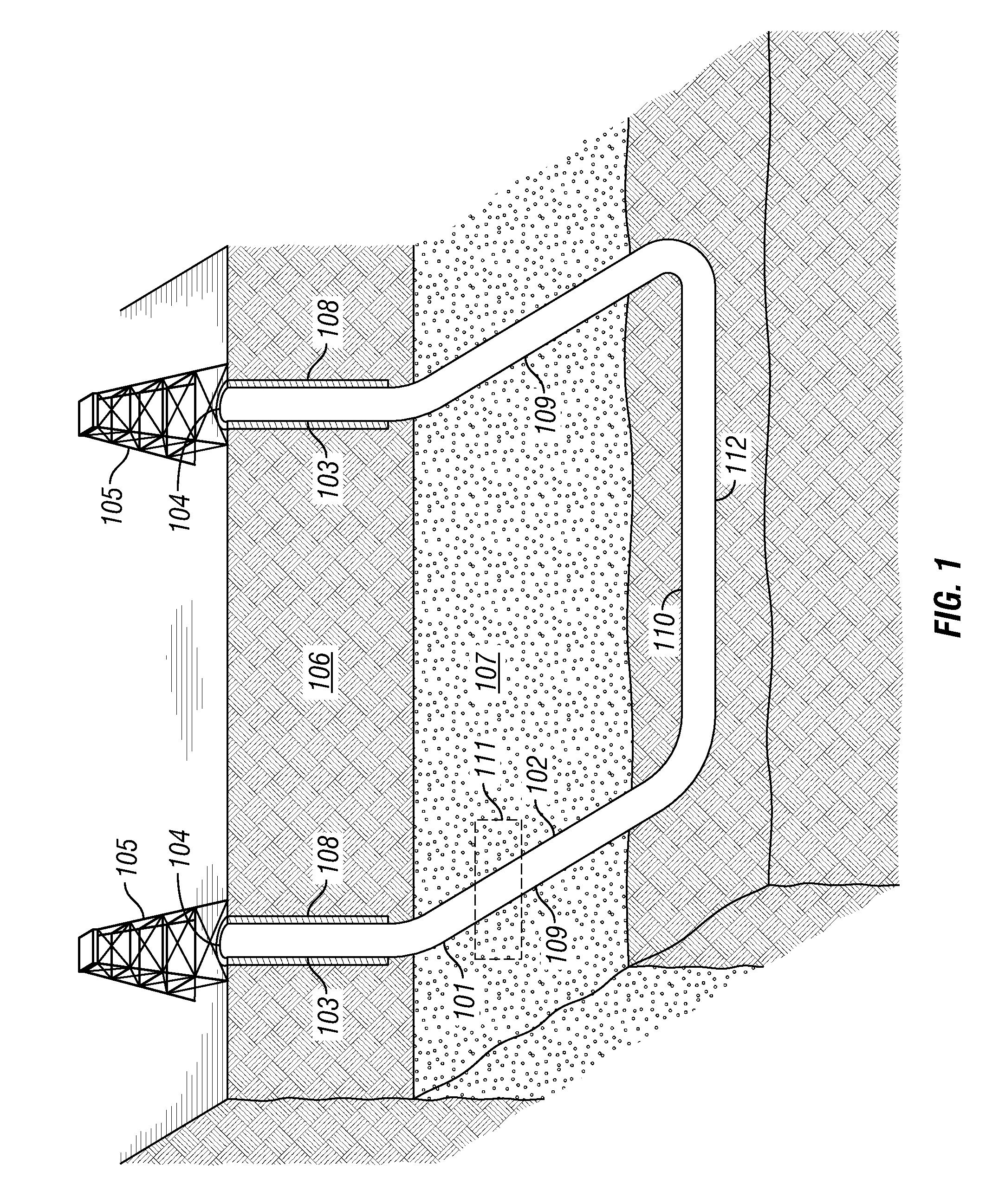

[0019]Referring now to FIG. 1, a wellbore 101 with a horizontal U-shaped section 102 is shown. The wellbore has substantially vertical sections 103 extending from surface locations 104 where drilling rigs 105 are placed. The vertical sections extend through overburden 106 and into a target formation 107 that could contain hydrocarbons such as, for example, natural gas. The sections of the wellbores that extend through the overburden may be cased with casings 108 that are cemented into place. The U-shaped section 102 preferably has two essentially parallel legs 109, connected by an essentially horizontal run 110. In some embodiments, the legs 109 could be tilted up, so that any hydrocarbon liquids produced from the wellbore after the well is completed would flow down to a point close to the vertical sections where they could be produced, by for example, an electrical submersible pump. Tilting up of the legs 109 may also facilitate the removal of cuttings as the slot is formed since t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com