Open pit mined-out area through hole plug and through hole plugging method thereof

An open-pit mine sealing and blocking technology, which is applied in the field of hole blocking, can solve the problems of large manpower and material resources, waste of explosives, and difficulties in blasting construction, and achieve the effects of improving filling efficiency, overcoming waste, and saving blasting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention can be explained in more detail by the following examples, the present invention is not limited to the following examples, the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention;

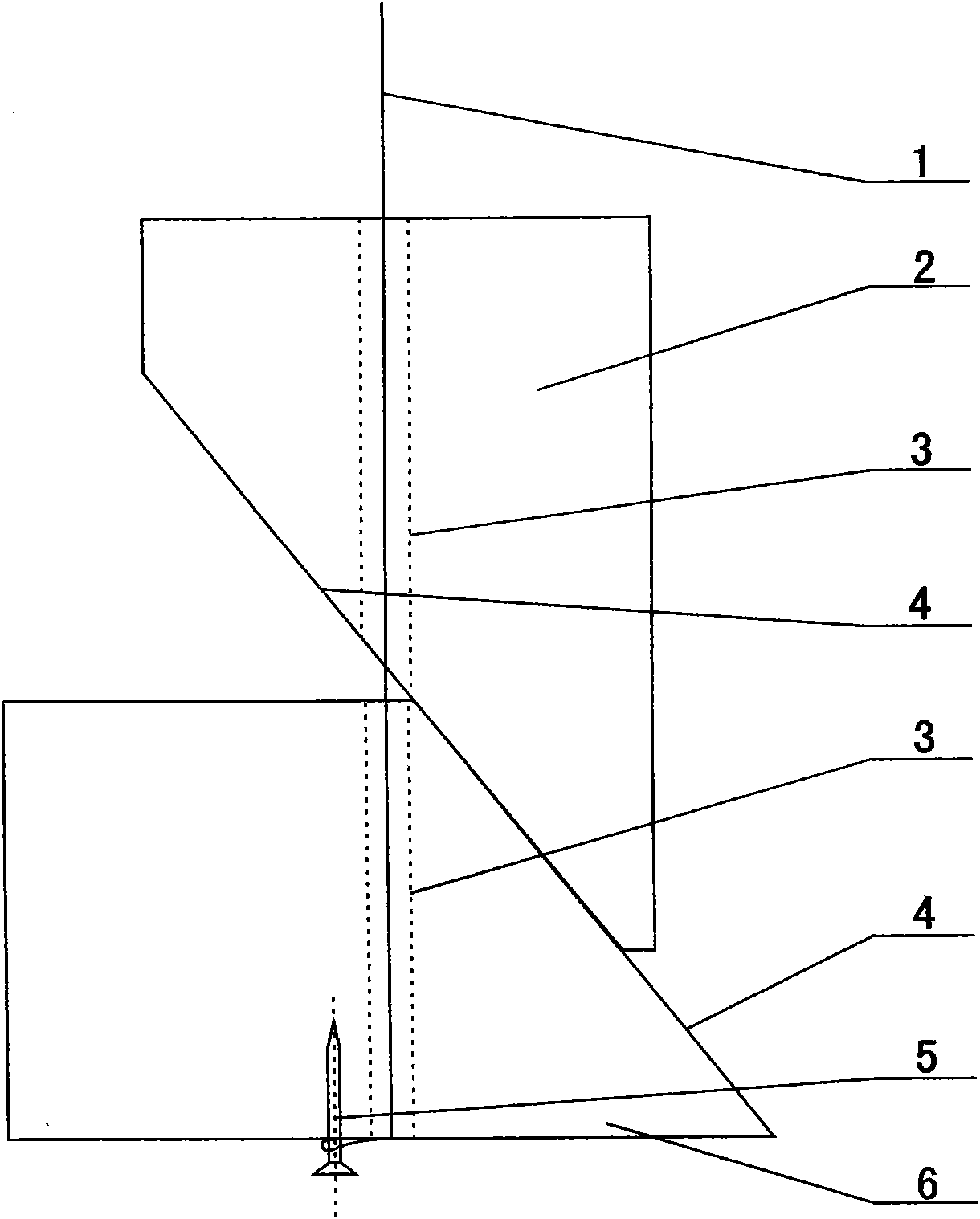

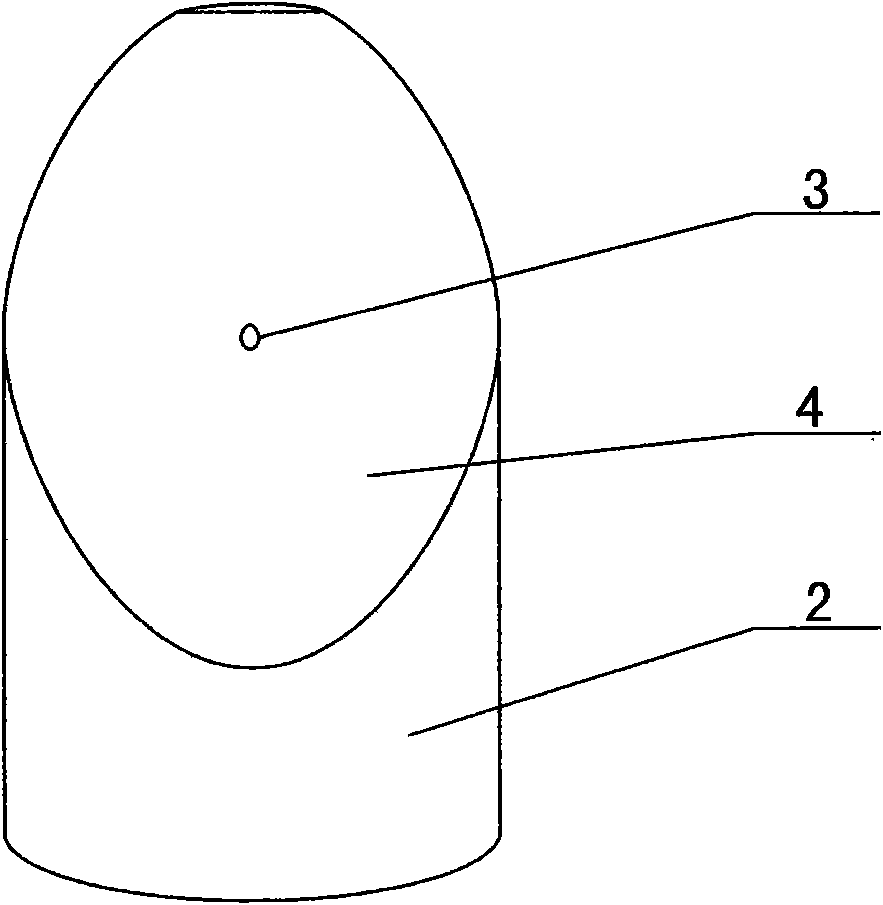

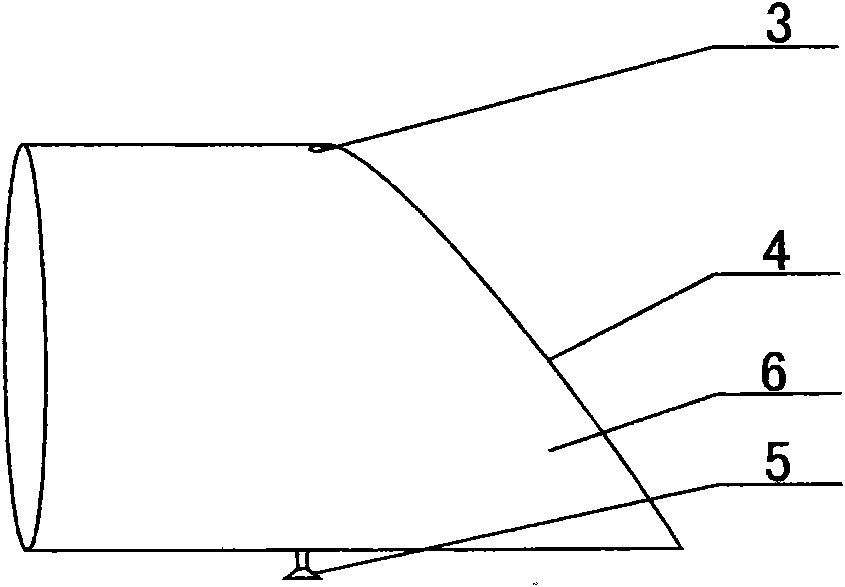

[0034] combined with figure 1 , 2 1. The through-hole sealing and plugging of the open-pit goaf described in 3 includes an upper wooden wedge 2, a main wooden wedge 6, iron nails 5 and iron wire 1, the upper end of the upper wooden wedge 2 is set as a plane, and the lower end is an inclined plane 4 and An iron wire 1 perforation 3 is set at the center of the upper plane of the upper wooden wedge 2 to the center of the lower end inclined plane 4, and one end of the main wooden wedge 6 is set as a plane, and the other end is an inclined plane 4, and an iron wire 1 perforation 3 is provided from the upper part to the lower part of the upper wooden wedge 2. Any side of the perforation 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com