Water delivery tunnel whole-section one-time blasting forming construction method

A technology for water conveyance tunnels and construction methods, which is applied in blasting, tunneling, earthwork drilling, etc., which can solve the problems of poor blasting effect, high cost, and low work efficiency, and achieve the effects of reducing blasting costs, reducing costs, and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Cloth holes

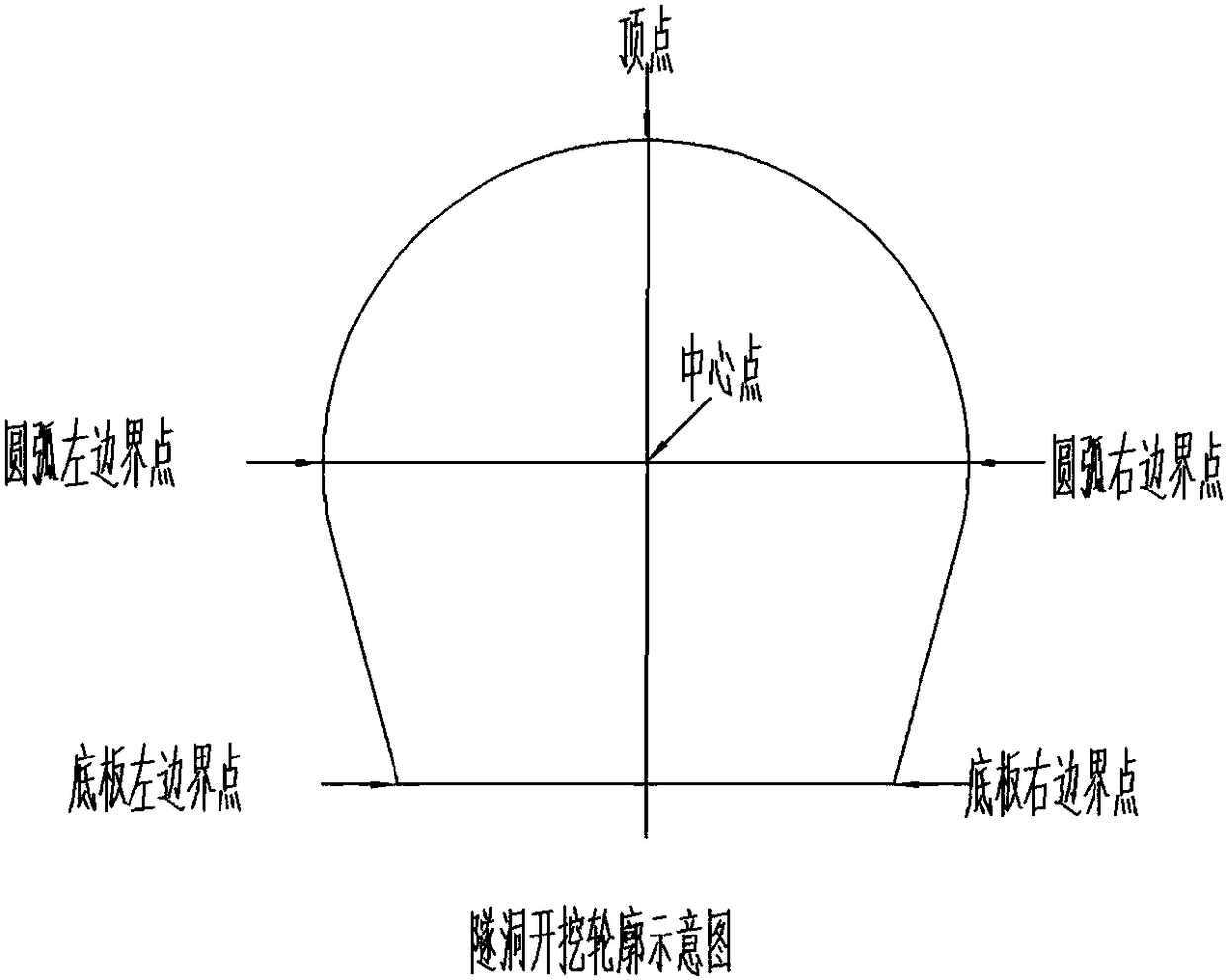

[0021] Before measuring and setting out, first clear the soil and broken layer on the surface of the tunnel face, use the total station to measure and release the tunnel face, draw the contour of the tunnel face, and then determine the vertex, center point, and upper semi-circular arc on the contour of the tunnel face Left and right boundary points, bottom left and right boundary points (such as figure 1 shown), and then stake out at the control points, and use a 5m tape measure to check the size between the boundary points on site to ensure that the stake out points are accurate.

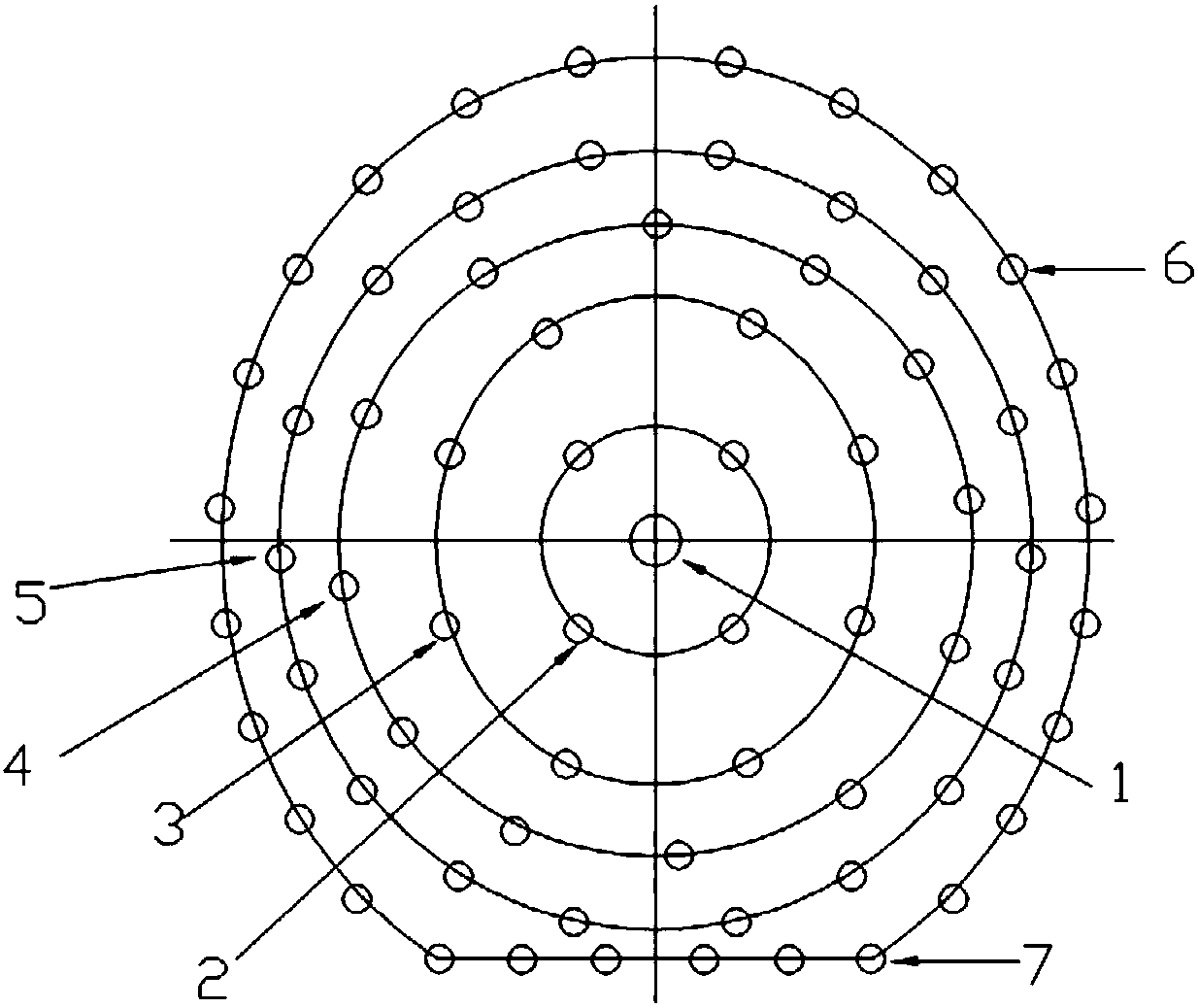

[0022] Take the center point of the face as the position of the center hole, surround the center hole, and determine the cutout eye, the first row of auxiliary eyes, the second row of auxiliary eyes, and the third row of auxiliary eyes on the face of the face from the inside to the outside. , the positions of the peripheral eye and the floor eye (the distribution is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com