Radial vacuum spaced charging device with active pressure relief

A technology of spaced charge and vacuum, applied in the field of blasting, can solve problems such as the unsatisfactory utilization rate of explosive energy, the inability to discharge the explosive energy in a timely and effective manner, and the inability to achieve blasting effect, so as to prolong the blasting time and improve the effective Utilization rate and the effect of reducing the unit consumption of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

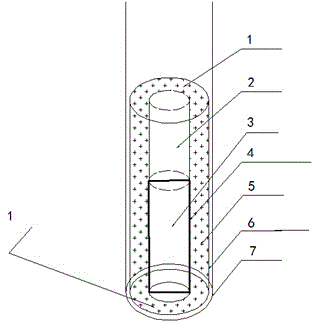

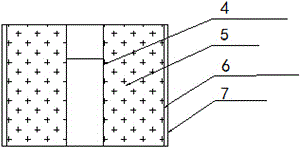

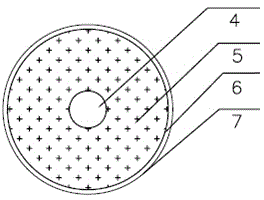

[0015] A radial vacuum interval charging device for active pressure relief, which includes an outer cavity 6, a vacuum medium layer 5 between the outer cavity 6 and the inner cavity 4, the two ends of the vacuum medium layer 5 are sealed by a sealing plate 1, and the inner cavity 4 The inside is filled with explosives 3, and the outer cavity 1, the inner cavity 4 and the sealing plate 8 form a sealed cavity, and the cavity is a vacuum medium 5. The part of the space not filled with explosives in the inner chamber 4 is the air medium layer 2 .

[0016] The distance between the outer cavity 1 and the blast hole wall 7 is 3-5 mm, so as to ensure that the outer cavity can be smoothly put into the blast hole.

[0017] The outer cavity 6, inner cavity 4 and sealing plate 1 are made of polyvinyl chloride, which has the characteristics of flexibility, pressure resistance, wear resistance, acid and alkali resistance, light weight, etc., and is convenient for transportation and low in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com