Method for peripheral hole non-coupling continuous loading

A charge and peripheral technology, applied in blasting and other directions, can solve the problems of uneven distribution of explosives, damage, inability to form a smooth and flat contour surface, etc., to achieve better blasting effect, smooth contour surface, and save detonating cords. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

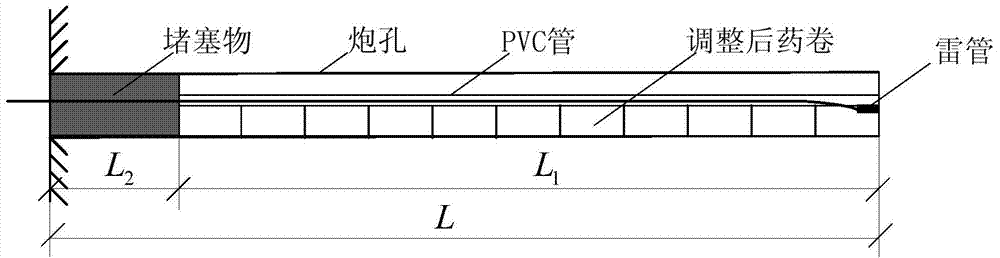

[0035] In the smooth blasting of tunnel excavation, the diameter of the surrounding hole is 42mm, the depth of the blasthole is 3.5m, the diameter of the emulsion explosive roll used on site is 35mm, the length of the roll is 20cm, and the mass of the roll is 180g; the surrounding rock is a relatively complete metamorphic rock, and the firmness coefficient Up to 12-16, the charge density of the peripheral hole line determined in the blasting design is 350g / m, and the charge length of the peripheral hole is 3.2m.

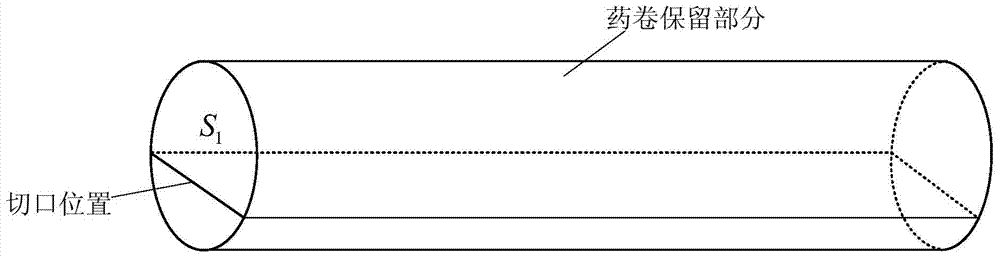

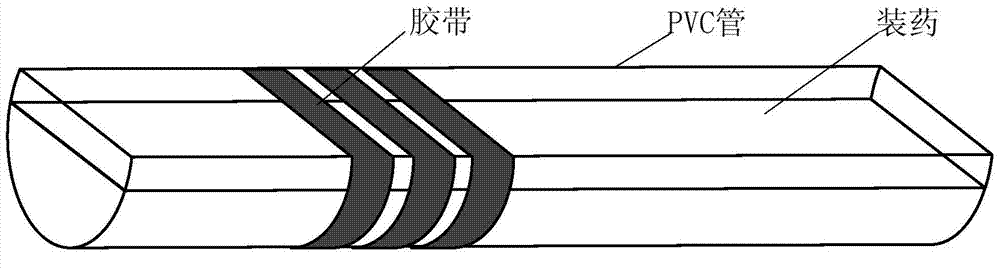

[0036] Attached figure 1 Determine the position of the incision of the drug roll according to the form, after calculation: the cross-sectional area required for the peripheral hole drug package is 3.7cm 2 , the total cross-sectional area of the original drug volume is 9.6cm 2 , determine the incision position according to the ratio, and cut the medicine roll. Choose a PVC pipe with an outer diameter of 30mm, cut it to a length of 3.2m, divide the PVC pipe mouth i...

Embodiment 2

[0039] In the smooth blasting of tunnel excavation, the diameter of the surrounding hole is 42mm, the depth of the blasthole is 3.5m, the diameter of the emulsion explosive roll used on site is 35mm, the length of the roll is 20cm, and the mass of the roll is 180g; the surrounding rock is a relatively complete metamorphic rock, and the firmness coefficient Up to 12-16, the charge density of the peripheral hole line determined in the blasting design is 350g / m, and the charge length of the peripheral hole is 3.2m.

[0040] Attached figure 1 Determine the position of the incision of the drug roll according to the form, after calculation: the cross-sectional area required for the peripheral hole drug package is 3.7cm 2 , the total cross-sectional area of the original drug volume is 9.6cm 2 , determine the incision position according to the ratio, and cut the medicine roll. Choose a PVC pipe with an outer diameter of 30mm, cut it to a length of 3.2m, divide the PVC pipe mouth i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com