Deep-hole blasting construction technology in fractured rocks

A technology of deep hole blasting and construction technology, applied in blasting and other directions, can solve problems such as difficulty in judging and evaluating the influence of joint cracks on blasting effect, inability to effectively eliminate the impact of joint crack blasting quality, etc., to save blasting costs, reduce The effect of destroying, eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

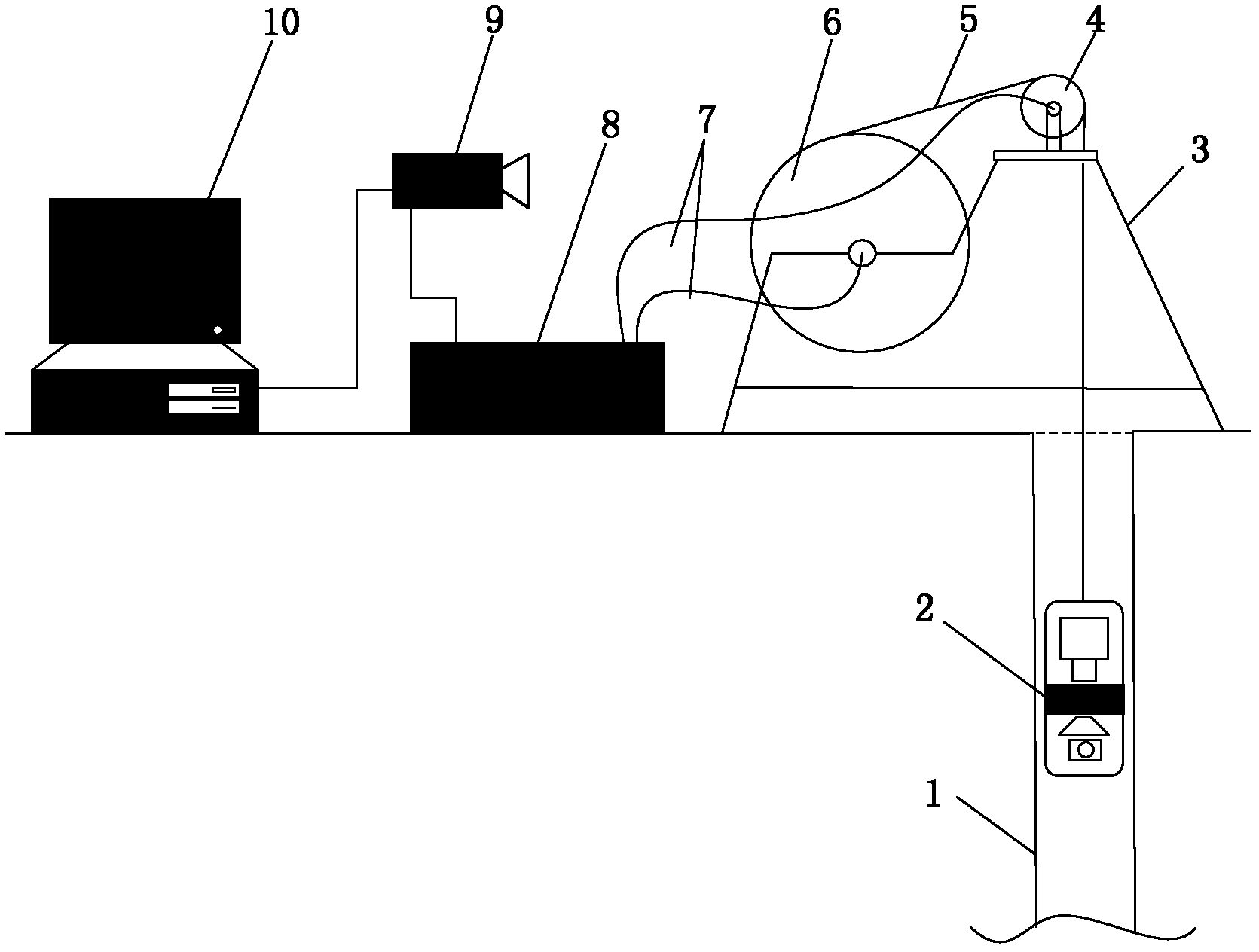

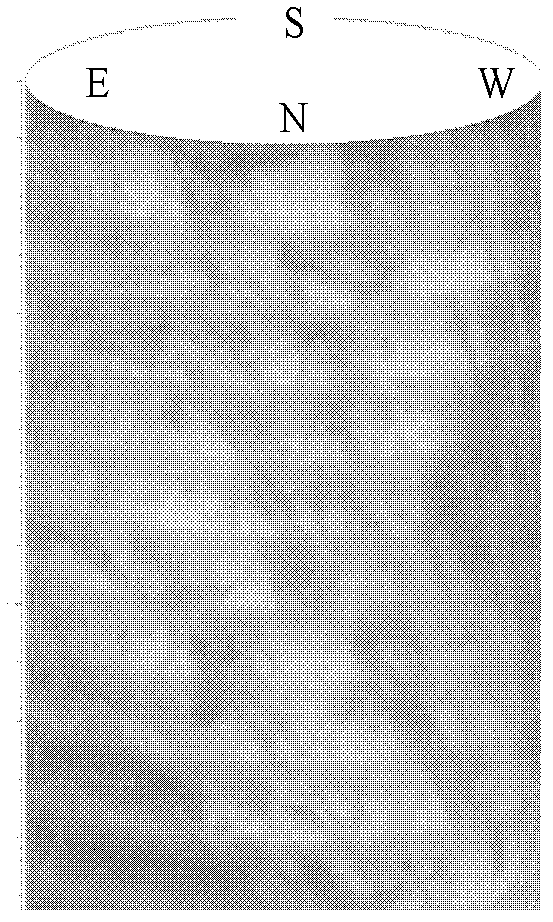

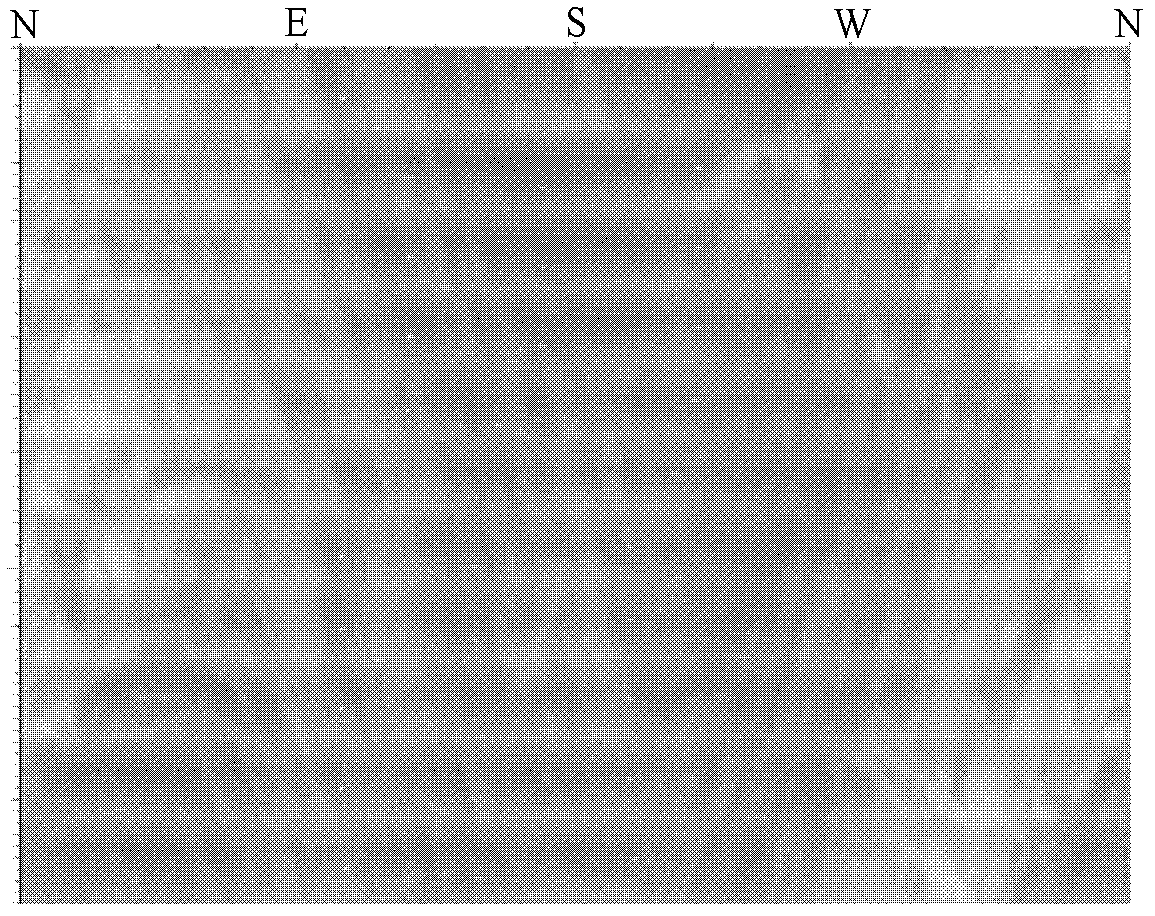

[0028] The deep hole blasting construction technology in the fractured rock mass provided by the present invention, according to the blasting action mechanism of rock joints and fissures, uses the drilling camera technology to first find out the occurrence, development degree, spatial position and other information of the joints and fissures on the inner wall of the borehole, and then According to the occurrence of joints and fissures in each borehole, the charge amount, charge structure, and blasting parameters of the blasting method are designed to improve the blasting effect, reduce the impact of cracks on the blasting quality, and reduce the blasting cost.

[0029] The process step that the present invention solves its technical problem adopts is:

[0030] (1) Draw the coordinate position map of the blast holes, and number each blast hole;

[0031] (2) Determine the diameter and depth of each blast hole;

[0032] (3) According to the coordinate position of each blasting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com