Bamboo-chip smooth wall protection blasting method for joint fissure mud rock slope

A technology of jointed fissures and bamboo chips, used in blasting, excavation, construction, etc., can solve the problems of destroying the integrity and stability of the rock mass inside the blasthole, unable to learn from the jointed rock mass, endangering construction and safety, etc. The effect of saving blasting cost, good applicability, and convenient processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

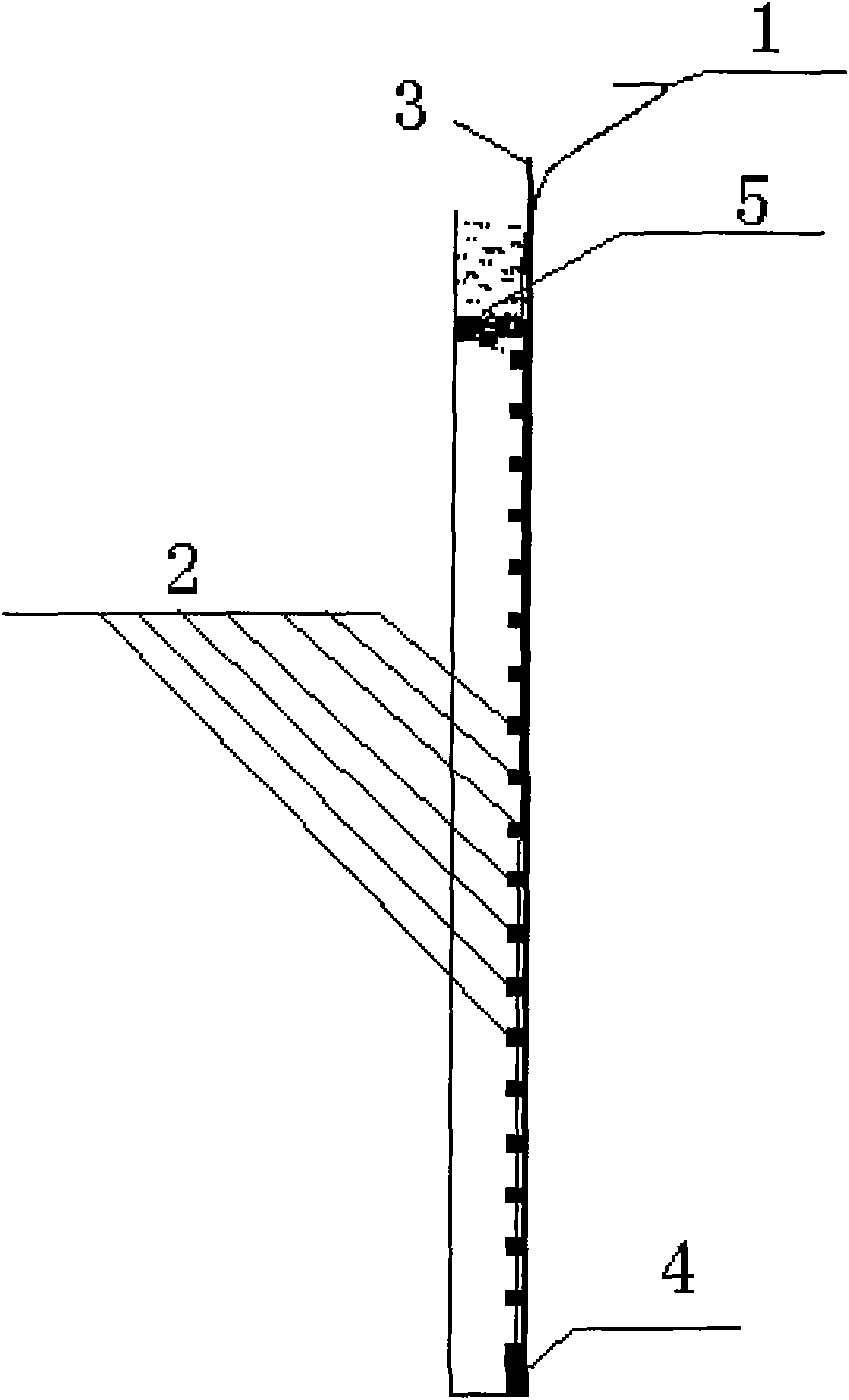

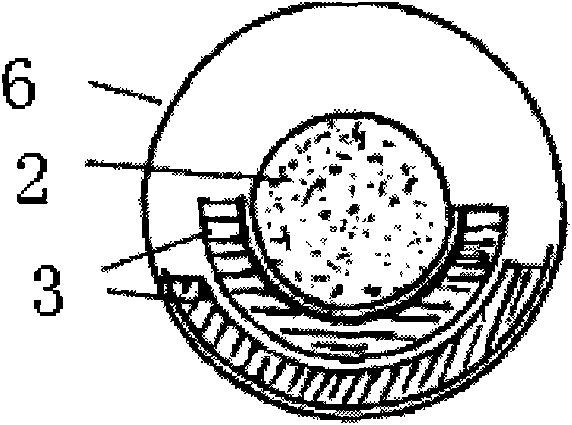

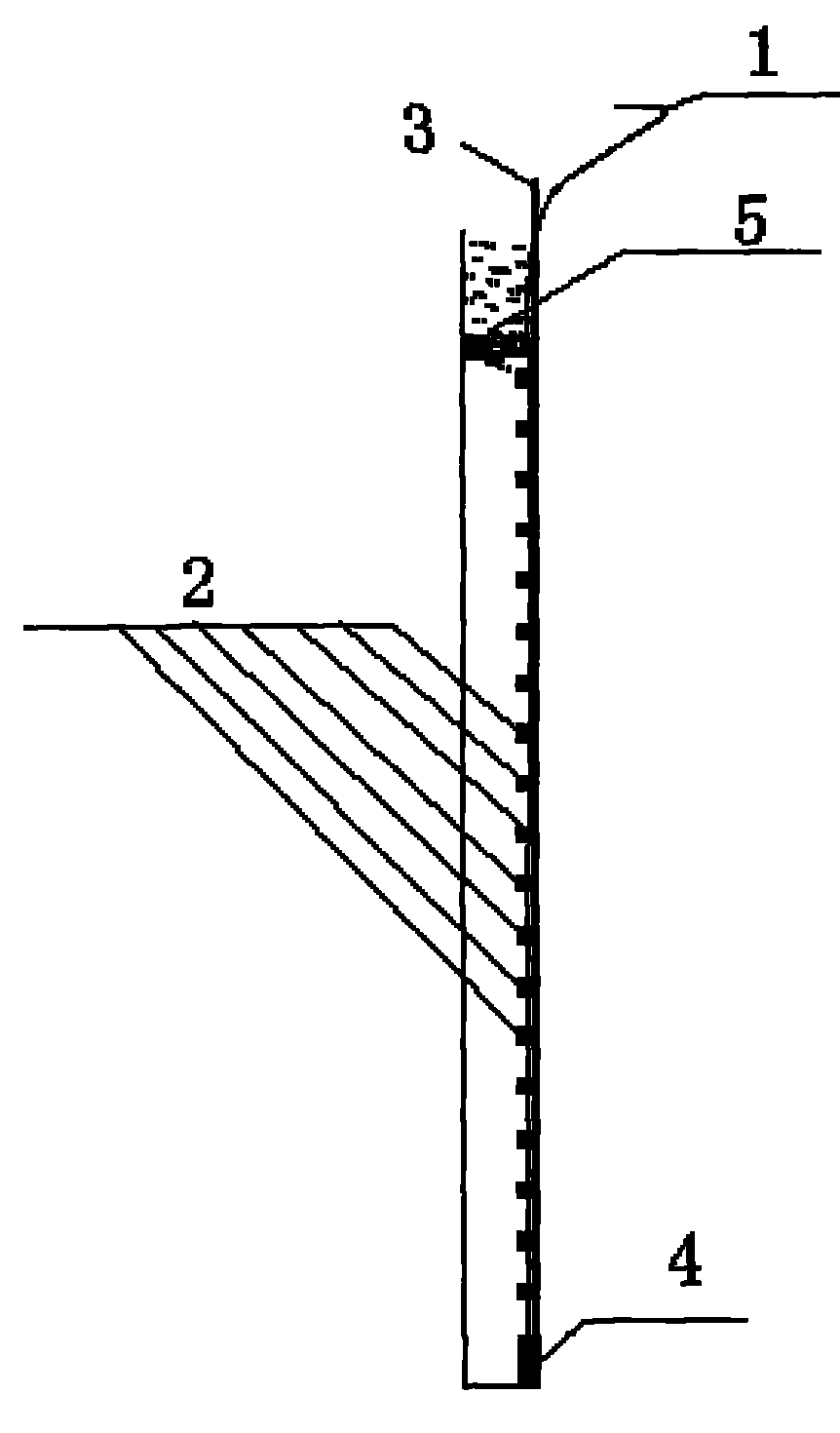

[0019] Aiming at the blasting excavation project of a highway slope, in order to reduce the damage caused by the explosion effect to the slope rock mass with retained joints and fissures, the smooth wall blasting technology was selected. After determining the blasting parameters according to the actual geological conditions, the charge structure of the optical blast hole is as follows: figure 1 , figure 2 shown.

[0020] When bundling the explosives, the detonating cord 1 is first inserted into the explosive at the reinforced part of the hole bottom, and then the detonating cord 1 and the charge roll are bound together on the bamboo sheet to form a protective wall charge; the charge roll 2 is bound on the retaining wall at intervals of 30 cm per roll. On the device 3, the wall protection device 3 is composed of double-layer bamboo sheets, and 4 rolls of medicine rolls are continuously bundled at the bottom of the bamboo sheets as the reinforced charge 4 at the bottom of the ...

Embodiment 2

[0022] A blasting method for smooth-faced bamboo protection walls of jointed and fissured mudstone slopes. In this method, drug rolls are tied to wall protection devices at intervals of 10 cm to form protection wall protection devices. The wall protection device is composed of two layers of arc-shaped bamboo chips. , the thickness of each layer of bamboo slices is 16mm, the width of the inner layer of bamboo slices is 1mm larger than the diameter of the explosive roll, and the width of the outer layer of bamboo slices is 1mm larger than the width of the inner bamboo slices; Back against the rock mass on the side of the rock, there is a gap of 3 cm between the medicine volume and the four walls of the blast hole, and the wall protection device is used to control the distribution of the explosion stress field, so that the cracks are cracked in the predetermined direction to form a cracking surface, so as to protect the rock mass on the side of the rock and break the impermanent F...

Embodiment 3

[0024] A blasting method for smooth-faced bamboo protection walls of jointed and fissured mudstone slopes. In this method, drug rolls are tied to wall protection devices at intervals of 50 cm to form wall protection drug rolls. The wall protection device is composed of five layers of arc-shaped bamboo chips. , the thickness of each layer of bamboo slices is 8mm, the width of the inner layer of bamboo slices is 5mm larger than the diameter of the explosive roll, and the width of the outer layer of bamboo slices is 5mm larger than the width of the inner bamboo slices; With its back against the rock mass on the side of the remaining rock, there is a 10cm gap between the medicine volume and the four walls of the blast hole. The wall protection device is used to control the distribution of the explosion stress field, so that the cracks are cracked in the predetermined direction to form a cracking surface, so as to protect the rock mass on the side of the remaining rock and break the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com