Deep hole blasting explosive cartridge

A technology of deep-hole blasting and blasting barrels, which is applied in the direction of blasting barrels, weapon accessories, offensive equipment, etc. It can solve the problems of PVC pipes that cannot be reused, misplaced cannons in the wrong position, and squibs that cannot be quickly recovered, etc., to achieve fast and stable charge, improve The success rate and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

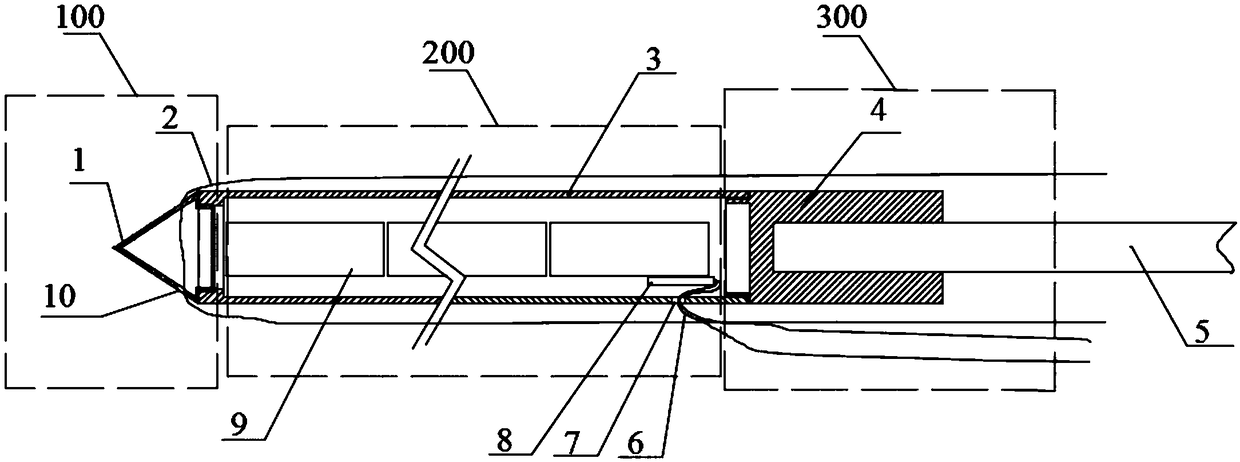

[0026] The present embodiment is based on the forward blasting charging method.

[0027] Such as figure 1 and Figure 5 As shown, a blasting cylinder for deep hole blasting includes a pilot device 100, a charging device 200 and a drug delivery device 300; Two through holes 10, a soft rope 2 passes through the through holes 10, half of the length of the soft rope 2 is greater than the depth of the drilled hole;

[0028] The charge device 200 includes a hollow cylindrical charge cartridge 3, a conical plug 1 is connected to one end of the charge cartridge 3, and a gun rope hole 7 is provided on the charge cartridge 3, and several explosive rolls 9 and A detonator 8 is used for detonation, and the gun rope 6 of the detonator 8 passes through the gun rope hole 7 and extends to the outer end of the borehole; When charging, the explosive rolls 9 are evenly arranged in the charge barrel in turn, and finally the detonator 8 is installed;

[0029] The drug delivery device 300 inclu...

Embodiment 2

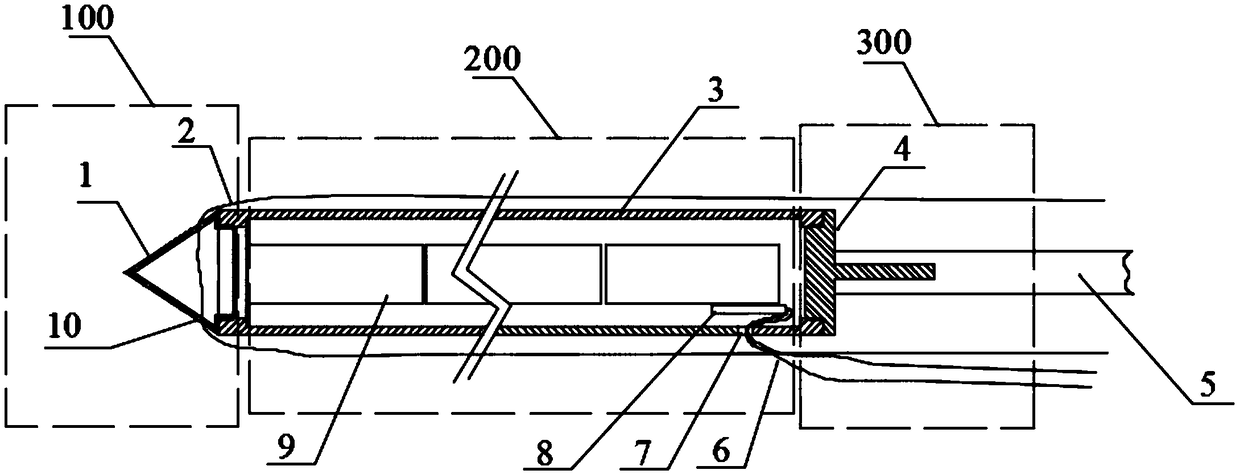

[0037] The present embodiment is based on the forward blasting charging method.

[0038] Such as figure 2 and Figure 5 As shown, a blasting cylinder for deep hole blasting includes a pilot device 100, a charging device 200 and a drug delivery device 300; Two through holes 10, a soft rope 2 passes through the through holes 10, half of the length of the soft rope 2 is greater than the depth of the drilled hole;

[0039] The charge device 200 includes a hollow cylindrical charge cartridge 3, a conical plug 1 is connected to one end of the charge cartridge 3, and a gun rope hole 7 is provided on the charge cartridge 3, and several explosive rolls 9 and A detonator 8 is used for detonation, and the gun rope 6 of the detonator 8 passes through the gun rope hole 7 and extends to the outer end of the borehole; When charging, the explosive rolls 9 are evenly arranged in the charge barrel in turn, and finally the detonator 8 is installed;

[0040] The drug delivery device 300 incl...

Embodiment 3

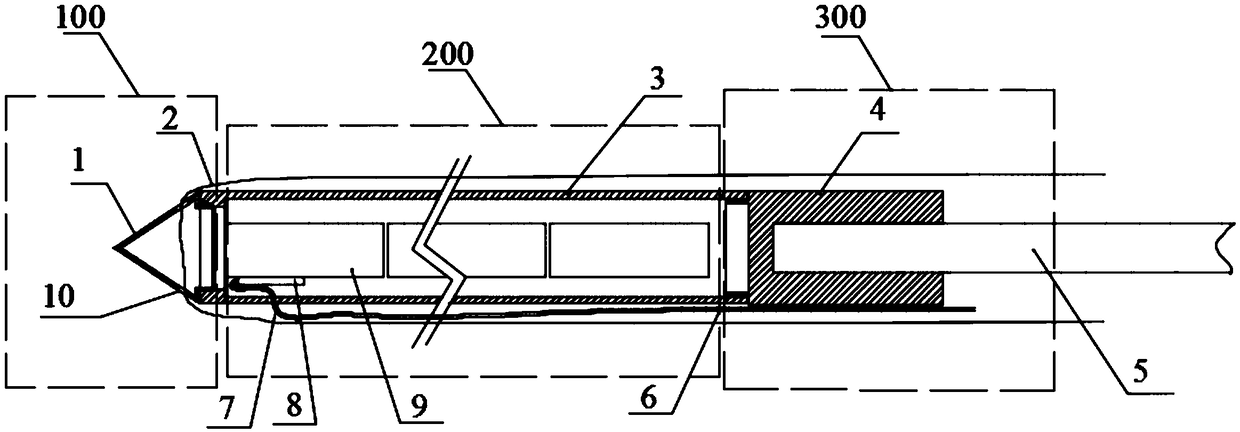

[0049] The present embodiment is based on the reverse blasting charge mode.

[0050] Such as image 3 and Figure 5 As shown, a blasting cylinder for deep hole blasting includes a pilot device 100, a charging device 200 and a drug delivery device 300; Two through holes 10, a soft rope 2 passes through the through holes 10, half of the length of the soft rope 2 is greater than the depth of the drilled hole;

[0051] The charge device 200 includes a hollow cylindrical charge cartridge 3, a conical plug 1 is connected to one end of the charge cartridge 3, and a gun rope hole 7 is provided on the charge cartridge 3, and several explosive rolls 9 and A detonator 8 for detonation, the gun rope 6 of the detonator 8 passes through the gun rope hole 7 and extends to the outer end of the borehole; the gun rope hole 7 is opened on the side wall of the cartridge 3 near the end of the tapered plug 1, When charging, the detonator 8 is first loaded into the cartridge 3, and then the explo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com