Simple smooth blasting drilling and charging method for medium-hard rock

It is a simple and simple technology for charging, which is applied in drilling equipment and methods, blasting, earthwork drilling and mining, etc. It can solve the problems of long drilling and charging time, long time spent, long time to reach the site, etc., and achieves The drilling and charging time is short, the cost of blasting is reduced, and the unit consumption of explosives is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

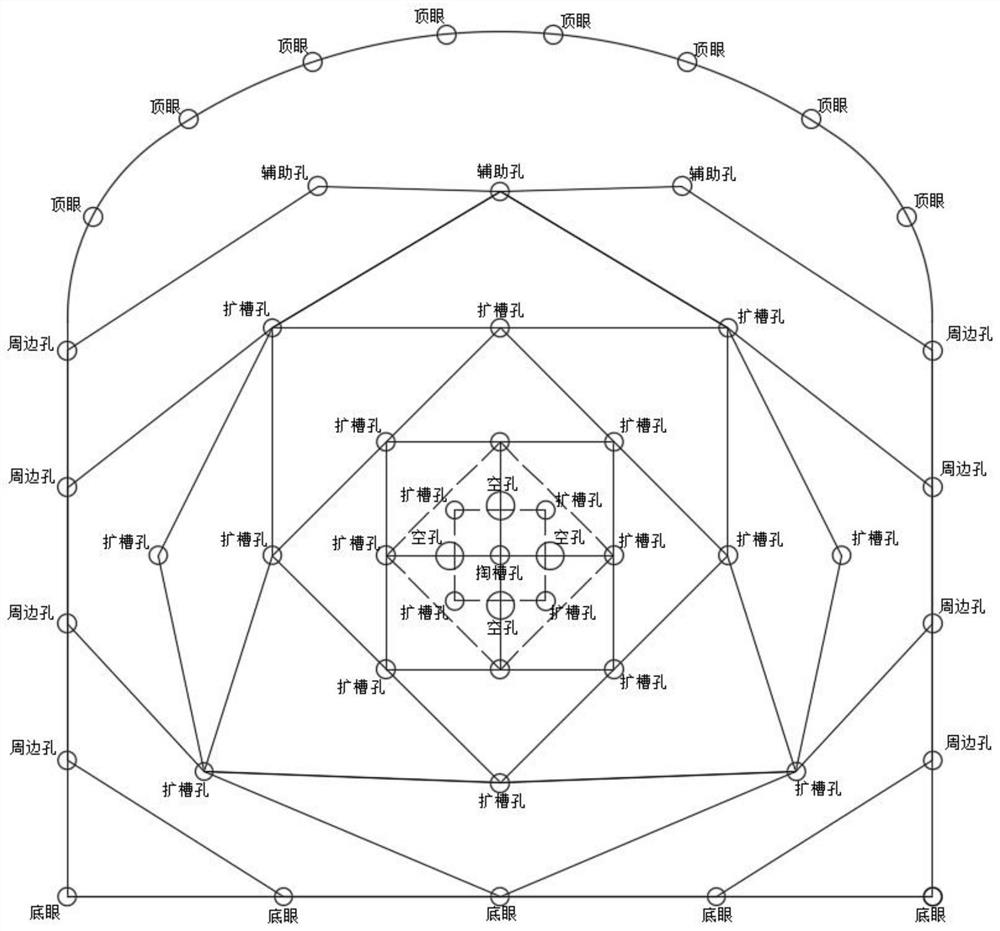

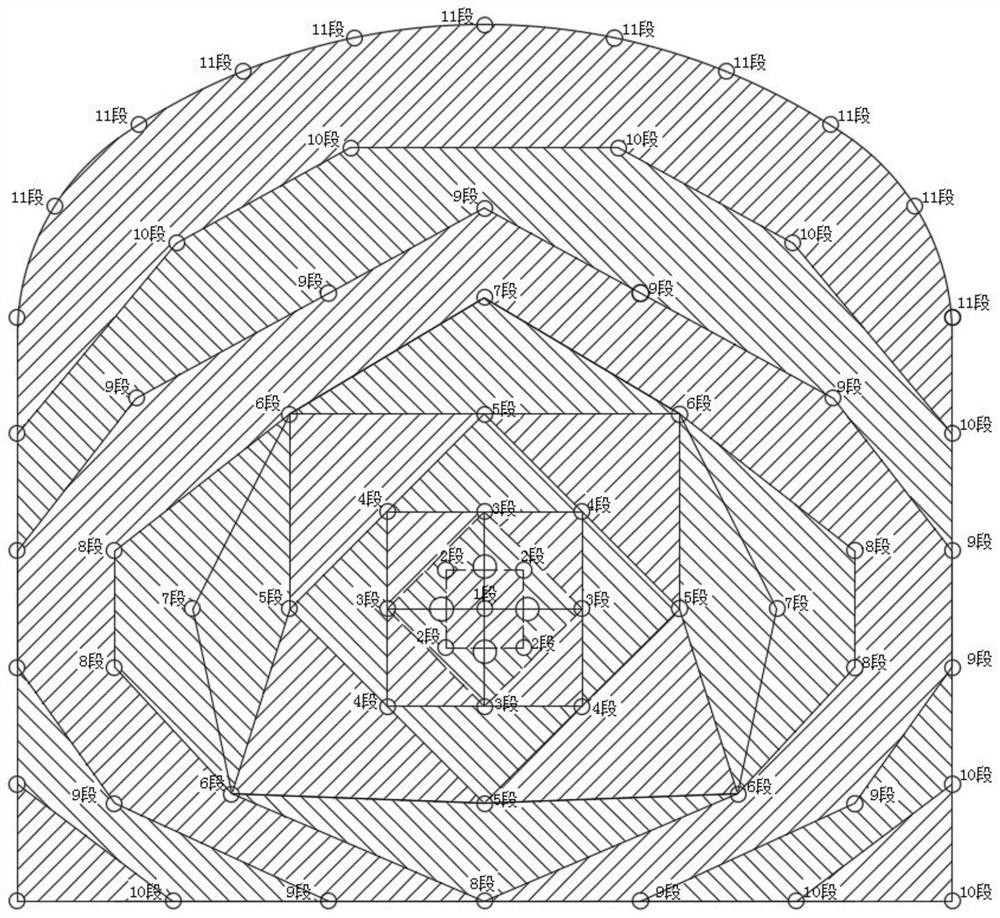

[0019] like figure 1 and figure 2 Shown; A kind of simple light explosion drilling and charging method that is used for medium hard rock, comprises the following operation steps:

[0020] S1. Rock drilling: firstly drill four empty holes, the first section of cutout hole is arranged in the center of the four empty holes, the second section of expansion hole is arranged within 200mm around the empty hole, and the second section of expansion hole is blasted with An expanded groove cavity is formed between each empty hole, and four 3-stage expanded groove holes are arranged around the diagonal corners of the groove cavity, and the distance between the four 3-stage expanded groove holes and the empty hole is 300mm;

[0021] S2. Positioning of multi-segment expansion holes: the expansion holes described in paragraphs 2, 3, 4, and 5 are alternately arranged in square and diamond shapes, and every four holes form a group, and the segments of the expansion holes are sequentially inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com