High-power water gel explosive applicable to coal mine and manufacturing method thereof

A technology for water-gel explosives and coal mines, used in explosives, blasting and other directions, can solve the problems of low chemical resistance efficiency of marble powder and reduced explosive energy of explosives, and achieve the effects of good chemical inhibition effect, increased explosive energy and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

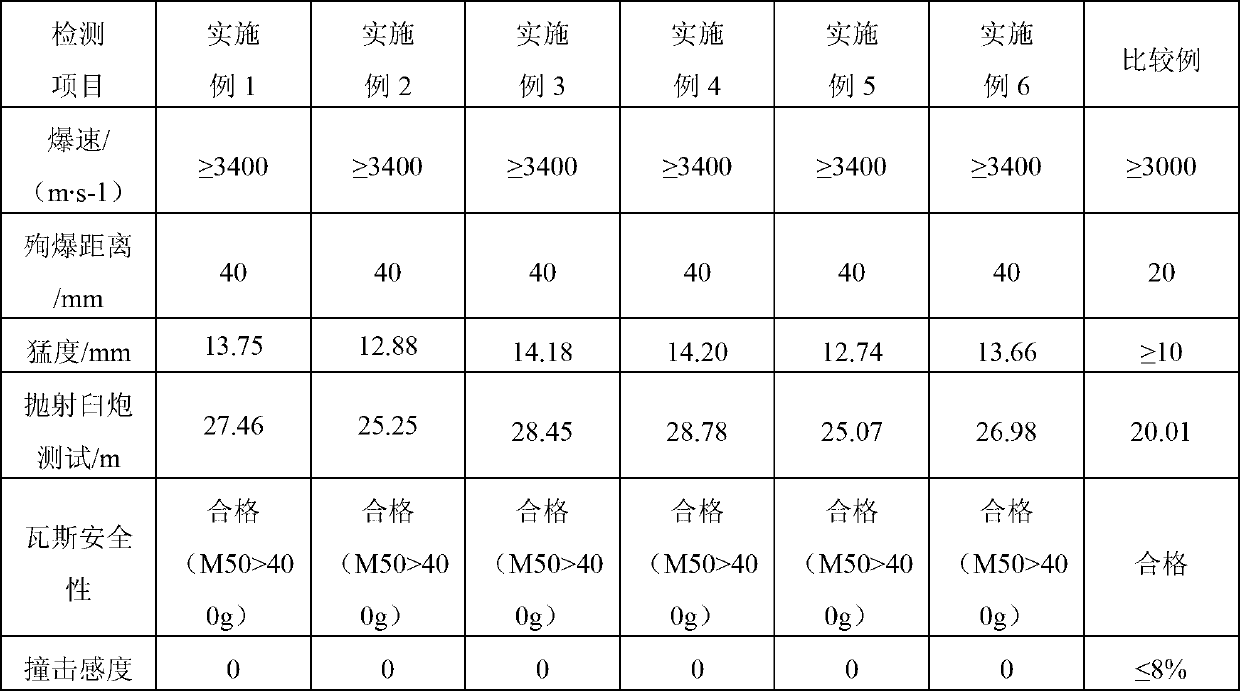

Examples

Embodiment 1

[0037] A high-power water-gel explosive for coal mines, in which the components are in parts by weight: 82% monomethylamine nitrate aqueous solution 38, powdered ammonium nitrate 35, sodium nitrate 8, high-efficiency flame suppressant 8, aluminum powder 0.5, fennel powder 0.9, glass beads 2, potassium dichromate aqueous solution with a concentration of 60% 0.3, fluorinated protein 0.2, among which the content of each component in the high-efficiency flame suppressant is potassium chloride 90%, ammonium chloride 5 %, water-resistant coating agent 5%; the content of each component in the water-resistant coating agent is: composite wax 94%, sodium lauryl sulfate 6%.

[0038] According to the above-mentioned components and content, the high-power three-grade coal mine permitted water-gel explosive of the present invention is made with the following preparation steps:

[0039] a. Mix and melt paraffin wax or compound wax and sodium lauryl sulfate at 110-120°C to make a water-resist...

Embodiment 2

[0046]A high-power third-grade coal mine permitted water-gel explosive, wherein the components are: 85% monomethylamine nitrate aqueous solution 36, powdered ammonium nitrate 34, sodium nitrate 9, high-efficiency flame suppressant 9, 0.8 aluminum powder, 0.9 squash powder, 2 glass beads, 0.2 potassium permanganate aqueous solution with a concentration of 60, 0.1 fluorinated protein, among which the content of each component in the high-efficiency flame suppressant is potassium chloride 88%, ammonium chloride 7%, water-resistant coating agent 5%; the content of each component in the water-resistant coating agent is: composite wax 92%, sodium lauryl sulfate 8%.

[0047] According to above-mentioned composition and content, according to the preparation procedure of embodiment 1, promptly make high-power three-grade coal mine permitted water-gel explosive.

Embodiment 3

[0049] A high-power third-grade coal mine permitted water gel explosive, wherein the components are as follows in parts by weight: 81% monomethylamine nitrate aqueous solution 40, powdered ammonium nitrate 34, sodium nitrate 9, high-efficiency flame suppressant 8, 0.9 aluminum powder, 0.9 squash powder, 2 expanded perlite, 0.2 potassium dichromate aqueous solution with a concentration of 60%, 0.1 fluorinated protein, and the content of each component in the high-efficiency flame suppressant is potassium chloride 91%, chloride Ammonium 6%, water-resistant coating agent 3%; the content of each component in the water-resistant coating agent is: composite wax 94%, sodium lauryl sulfate 6%.

[0050] According to above-mentioned composition and content, according to the preparation procedure of embodiment 1, promptly make high-power three-grade coal mine permitted water-gel explosive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com