Pre-split blasting combined explosive charging method, explosive charging structure and auxiliary device

A technology of pre-splitting blasting and auxiliary devices, applied in blasting and other directions, can solve the problems of high labor intensity and low charging efficiency, and achieve the effect of reducing labor intensity, reducing manpower and material resources, and ensuring the quality of charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

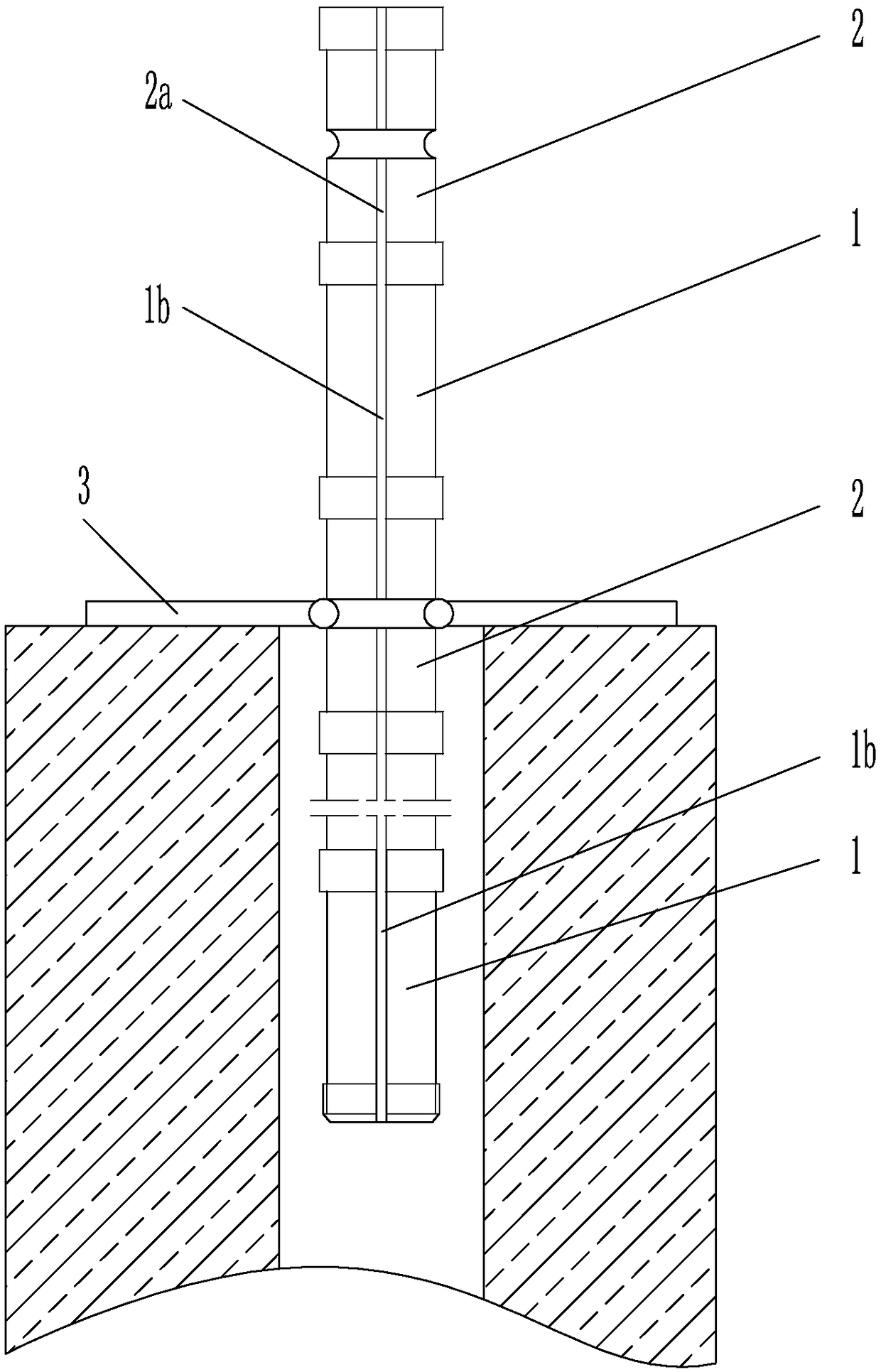

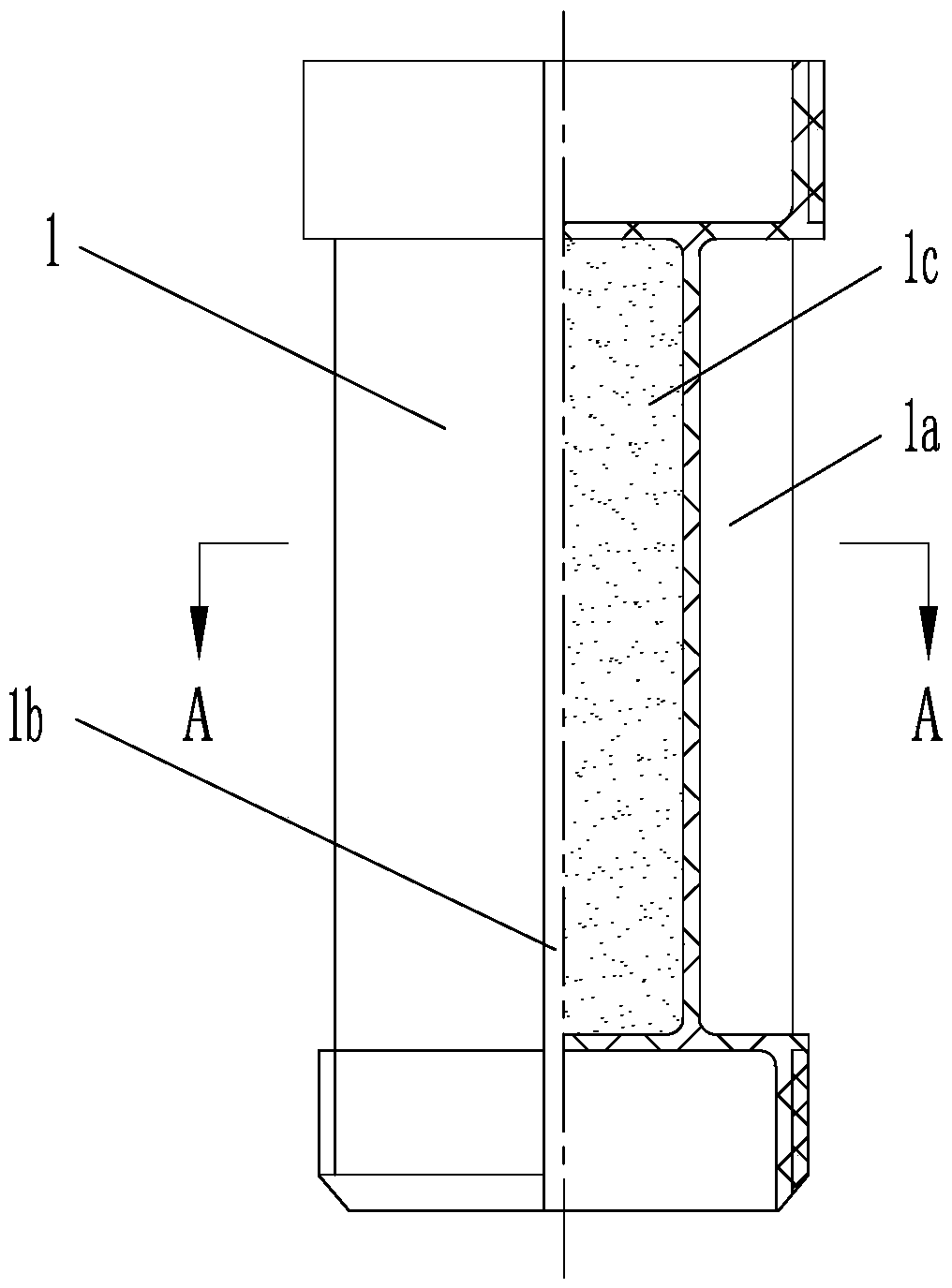

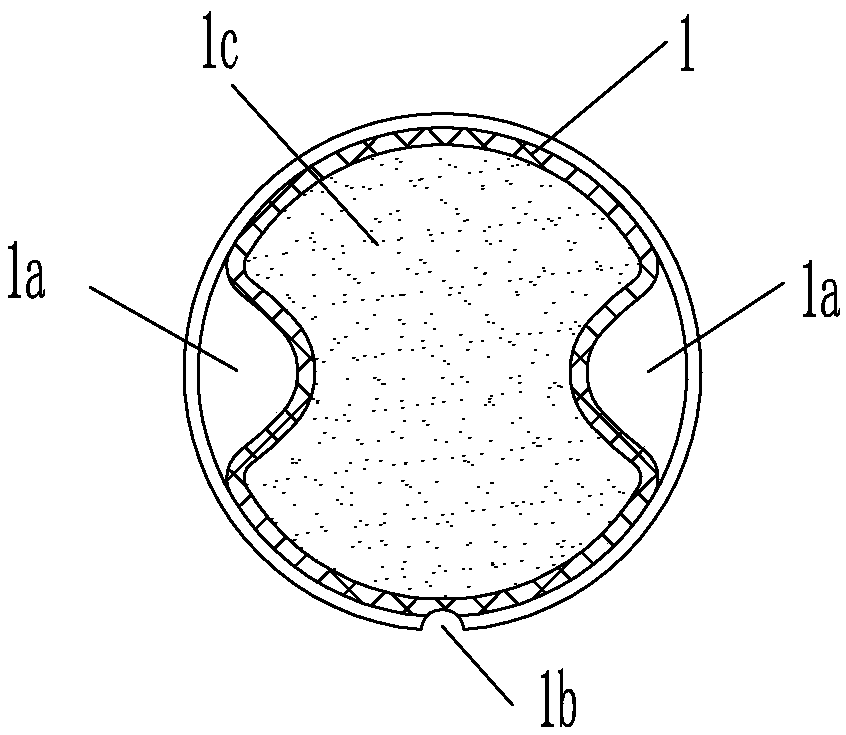

[0030] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , a pre-splitting blasting combined charge method for forming at least two charge sections and at least one spacer section in a blasthole, comprising forming at least one shaped charge column 1 into a corresponding charge section; forming at least one shaped spacer The column 2 forms a corresponding spacer section; and, a step of connecting a shaped charge column 1 and a formed spacer column 2 to form a charge section and a spacer section; wherein, the side wall of the shaped charge column 1 is formed with two lines in the shape of 180 The U-shaped energy-gathering groove 1a with a high-degree distribution, the U-shaped energy-gathering groove 1a extends axially along the formed charge 1; the first detonating cord groove 1b is formed between the two U-shaped energy-gathering grooves 1a, and the formed charge 1 passes through The explosive powder column is formed by injection molding; the molded spacer column ...

Embodiment 2

[0034] Embodiment 2, see figure 1 , figure 2 , image 3 , Figure 4 , a combined charge structure for pre-splitting blasting, at least two shaped charge columns 1 and at least one formed spacer column 2 are connected in series to form at least two charge sections and at least one spacer section in the blasthole; the shaped charge column 1 and the formed spacer column 2 both have a circular tank structure; the two ends of the formed drug column 1 and the formed spacer column 2 are respectively formed with internal and external threads of the same specification; the middle part of the tank wall of the formed spacer column 2 is formed with an annular groove 2b.

[0035] Wherein, the shaped charge 1 is formed by injecting and encapsulating the explosive charge; two U-shaped energy-gathering grooves 1a distributed at 180 degrees are formed on the side wall of the shaped charge 1, and the U-shaped energy-gathering grooves 1a along the The shaped charge 1 extends axially; a firs...

Embodiment 3

[0036] Embodiment 3, see Figure 5 , an auxiliary device 3 for pre-splitting blasting combined charges, including a C-shaped caliper 3a, and at least three handles 3b are fixedly connected radially on the C-shaped caliper 3a. In this embodiment, there are four, C-shaped The diameter of the caliper 3a matches the annular groove 2b on the formed spacer column 2 described in Embodiment 1 or Embodiment 2.

[0037] Wherein, the C-shaped caliper 3a and the handle 3b are both made of synthetic plastics, and the synthetic plastics are composed of the following components, wherein 60-90 parts of PA plastic nylon particles, 3-10 parts of carbon fiber particles, ultra-high molecular weight 10-20 parts of polyethylene fiber filaments, 2-5 parts of lubricant.

[0038] The following introduces the practical application of applying the method of embodiment 1 and the auxiliary device 3 of embodiment 3 to form the combined charge structure of embodiment 2 in the blast hole.

[0039] Case 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com