Storage battery charging device

A charging device and storage battery technology, applied in the direction of battery circuit devices, circuit devices, circuits, etc., can solve the problems of easy failure, inconvenient use of charging clips, etc., to save maintenance costs, ensure charging quality, and avoid poor charging and discharging contacts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

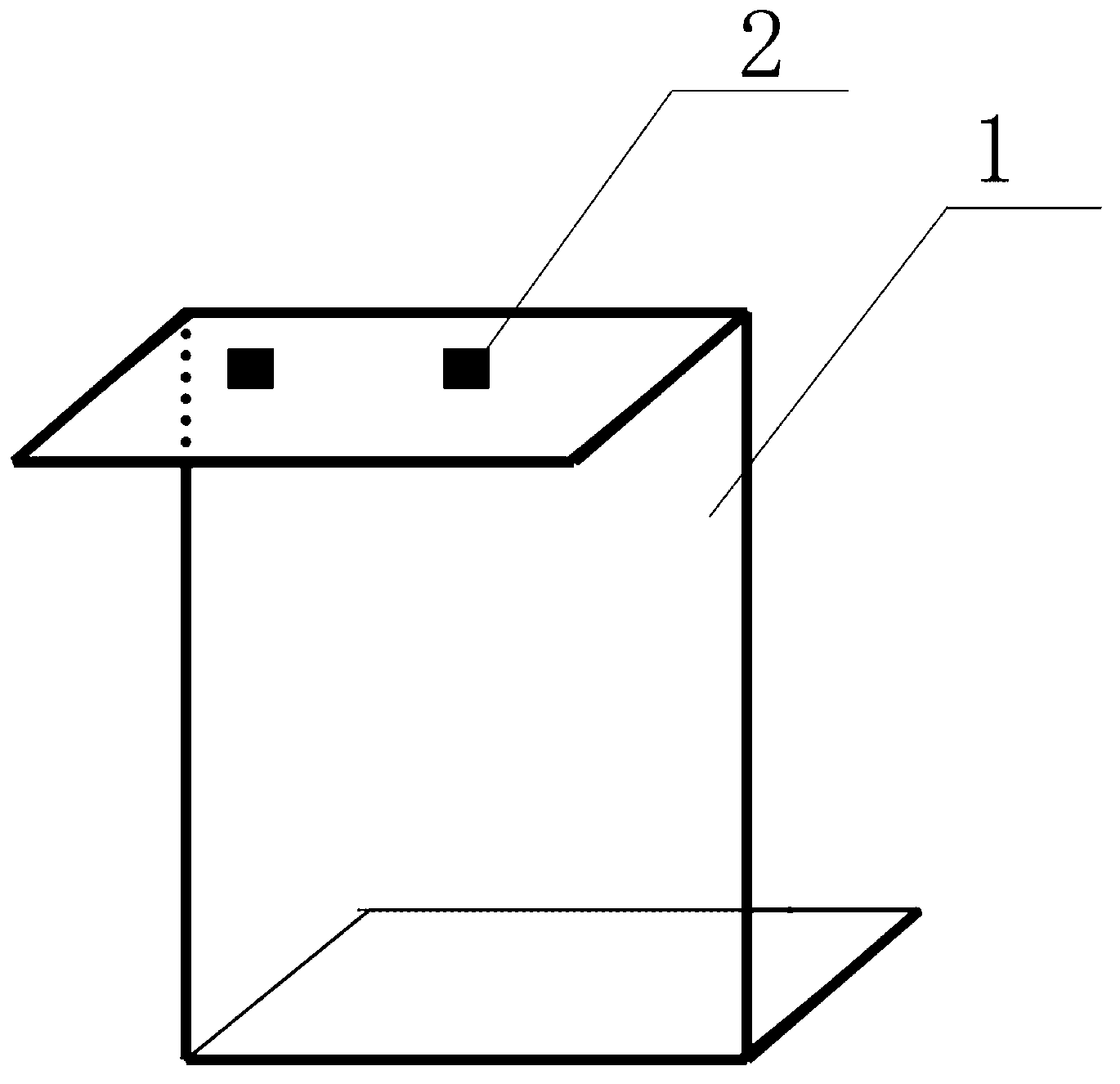

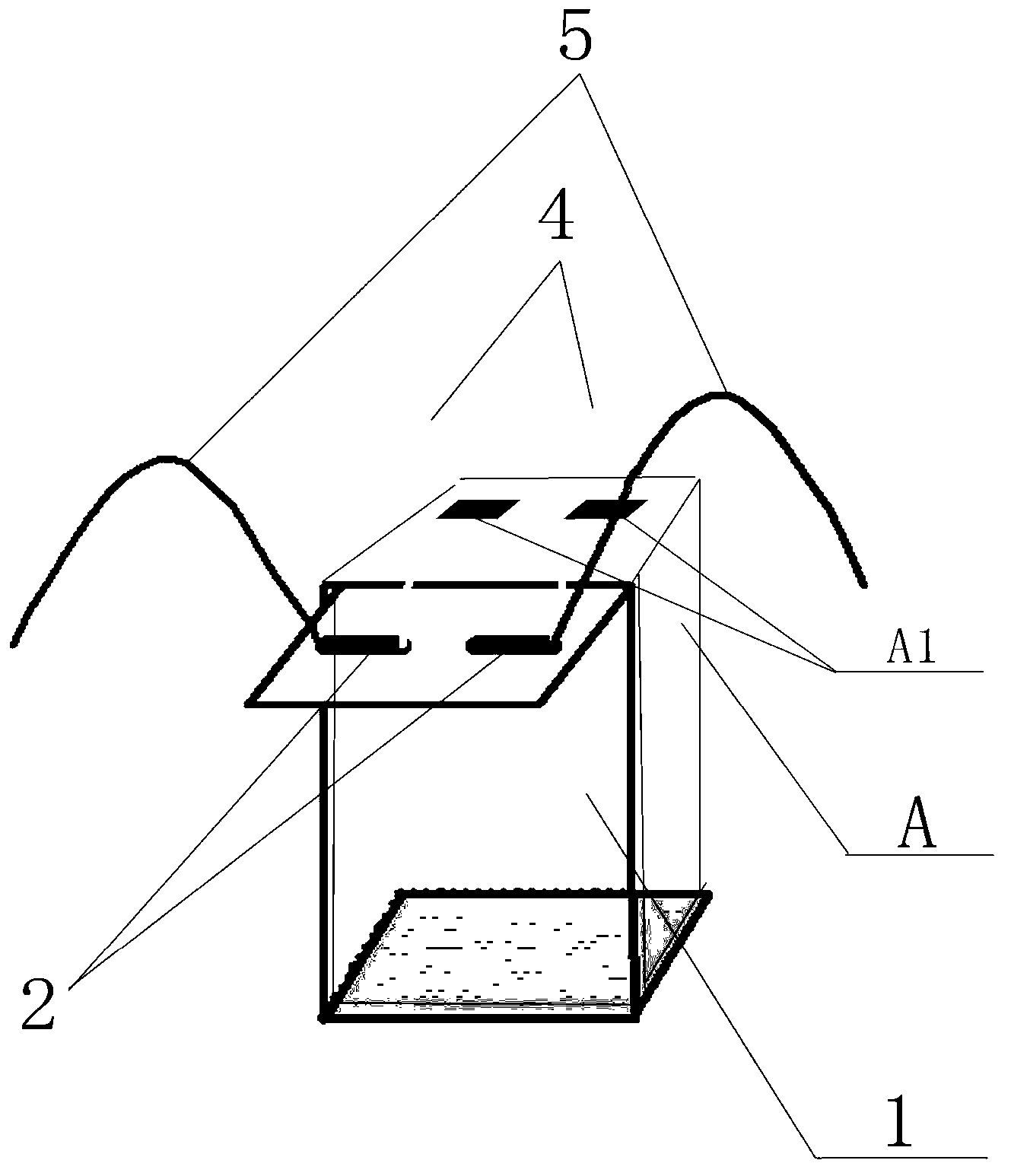

[0039] Such as Figure 1-4 As shown, the battery charging device includes a charging plate 1, which is Z-shaped, and two permanent magnets 2 corresponding to the positive and negative poles A1 of the battery are arranged on the top of the charging plate 1, and the battery A is set and pressed on The protruding surface of the bottom of the charging board 1 presses the charging board 1 tightly, and the two permanent magnets 2 are connected to the positive and negative poles A1 of the battery through the battery connecting wire 4 . In this embodiment, the connecting clip of the battery connecting wire 4 is a connecting clip 4.1 with a middle punch hole, and the punch hole can be connected to the positive and negative poles A1 of the battery with copper or stainless steel bolts. This solution can be applied to a small ampere hour, such as a battery A of 12-20 ampere. In addition, the two battery connecting wires 5 are respectively connected with the two permanent magnets 2 . In ...

Embodiment 2

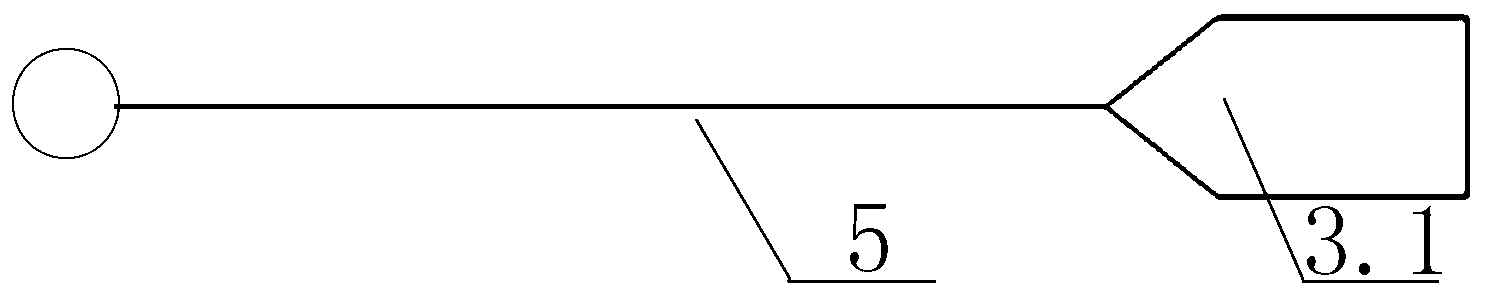

[0042] Such as Figure 5-7 As shown, this embodiment includes four charging boards 1, the charging boards 1 are Z-shaped, and two permanent magnets 2 corresponding to the positive and negative poles A1 of the storage battery are arranged on the top of the charging board 1, and the storage battery A is arranged to be pressed in the charging position. The charging board 1 is pressed tightly on the protruding board surface at the bottom of the board 1. In this embodiment, the battery A is installed in the same way as the charging board 1, so the battery A is not shown in the accompanying drawings. In this embodiment, the four charging boards 1 are connected in series through the top permanent magnet 2 and the series line 3, and the series line 3 is as figure 2 As shown, it includes two connecting magnets 3.1, the connecting magnets 3.1 are wrapped with lead, and the two connecting magnets 3.1 are connected by wires. Battery connection wire 5 structure is identical with embodime...

Embodiment 3

[0044] Such as Figure 8-9 As shown, in this embodiment, the difference from Embodiment 2 is that one end of the battery connection wire 4 is a connection magnet 3.1, and the other end is a connection card 4.3 with a tapered lead sleeve, and they are connected by wires in the middle. In this embodiment, a method for observing the charging status is shown. During charging, any serial line 3 can be removed at any time and connected in series with an ammeter 6 to observe the charging status, so that it is convenient to observe the change of the power at any time. In addition, In this embodiment, the positive and negative poles A1 of the storage battery are wrapped with thin lead, which can reduce the corrosion of sulfuric acid vapor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com