Pre-buried warhead fuze chamber and charging method

A warhead and fuze technology, which is applied in the directions of ammunition, offensive equipment, weapon accessories, etc., can solve the problems of increasing detonation distance, affecting the reliability of detonation, and unstable fixation, and achieves high safety and stable detonation distance. The effect of controllable and guaranteed charge quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

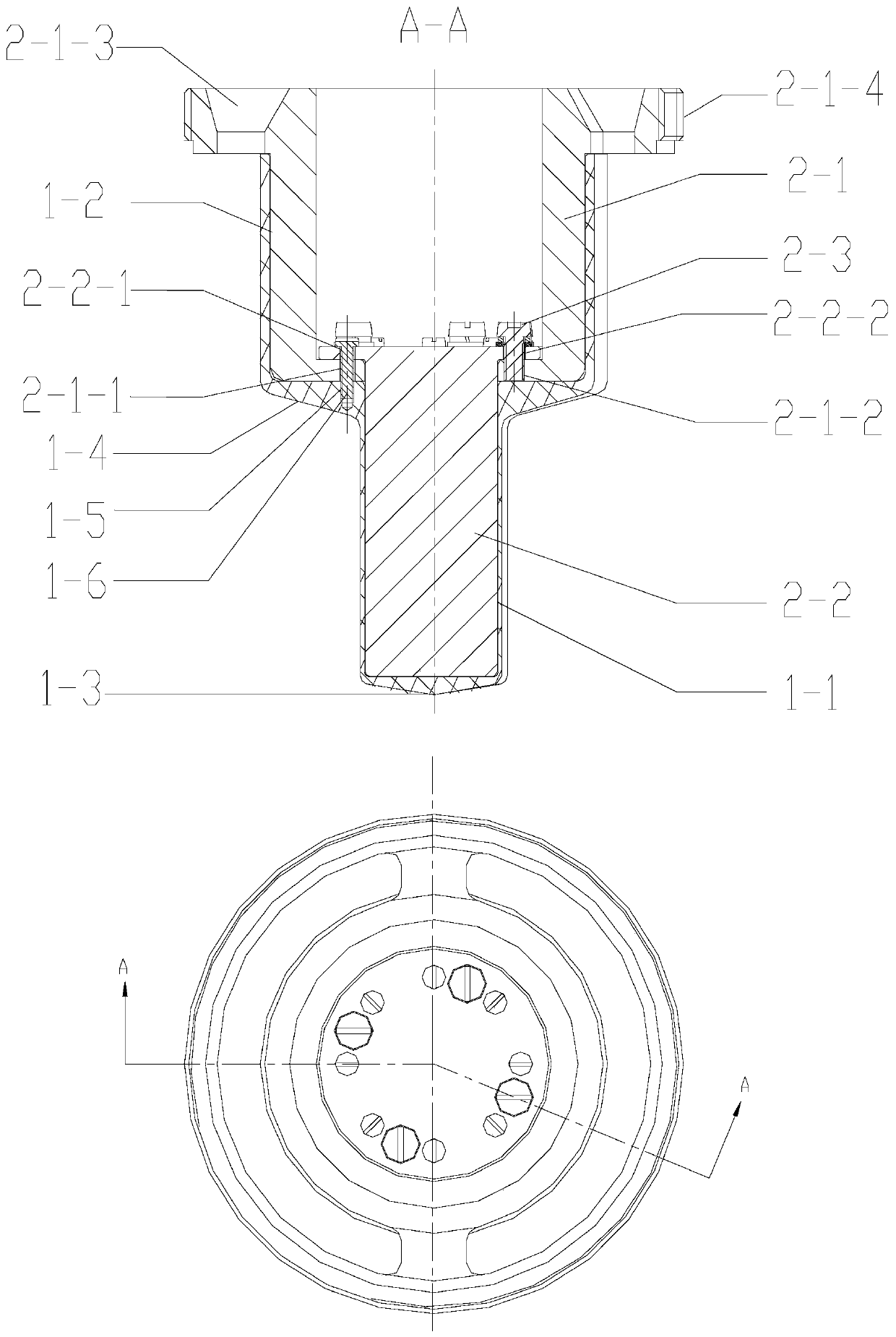

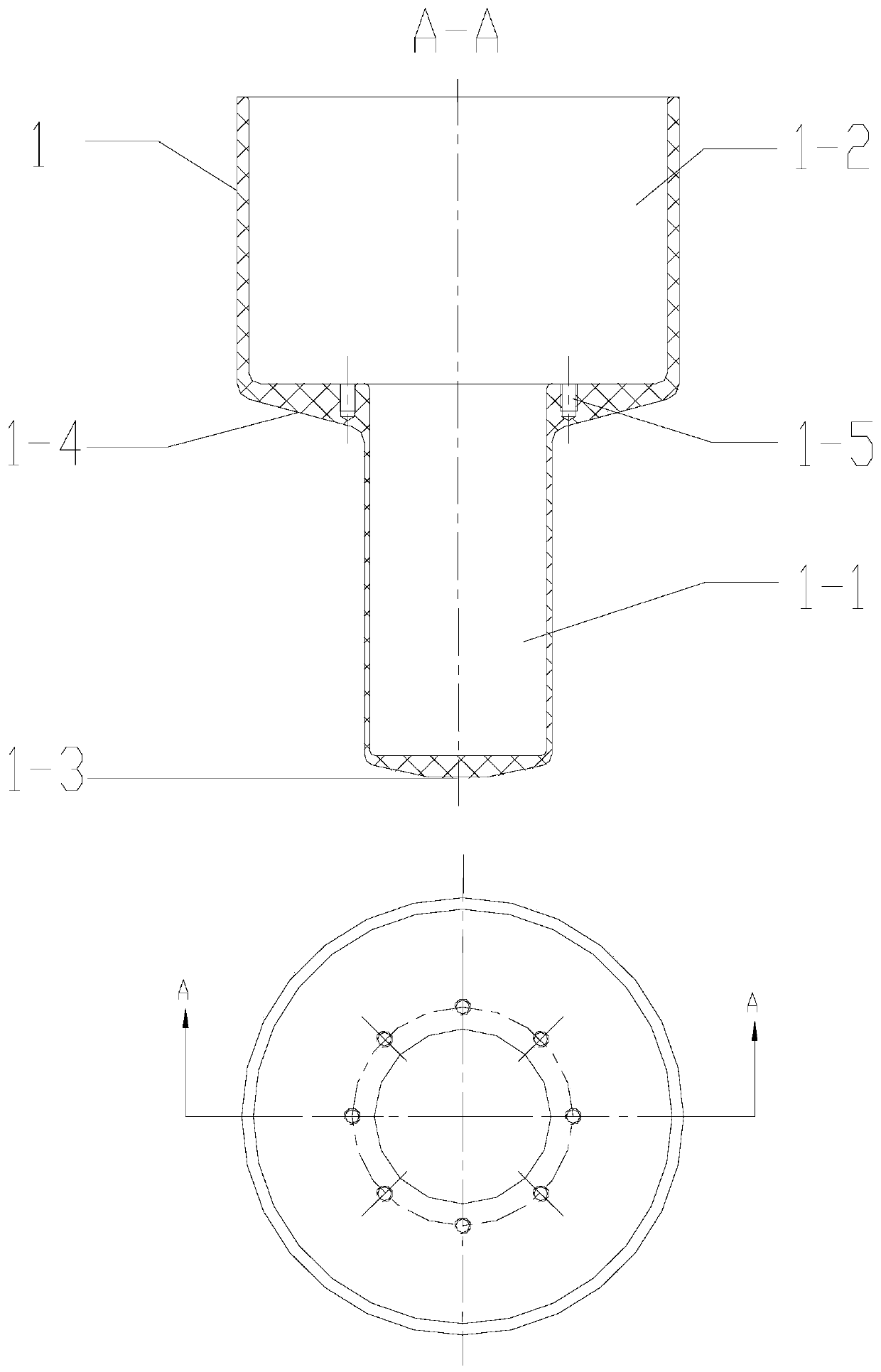

[0062] Embodiment 1: when the charge inner chamber 1-8 surface of the warhead 1-7 projectile contains thread 2-1-4a

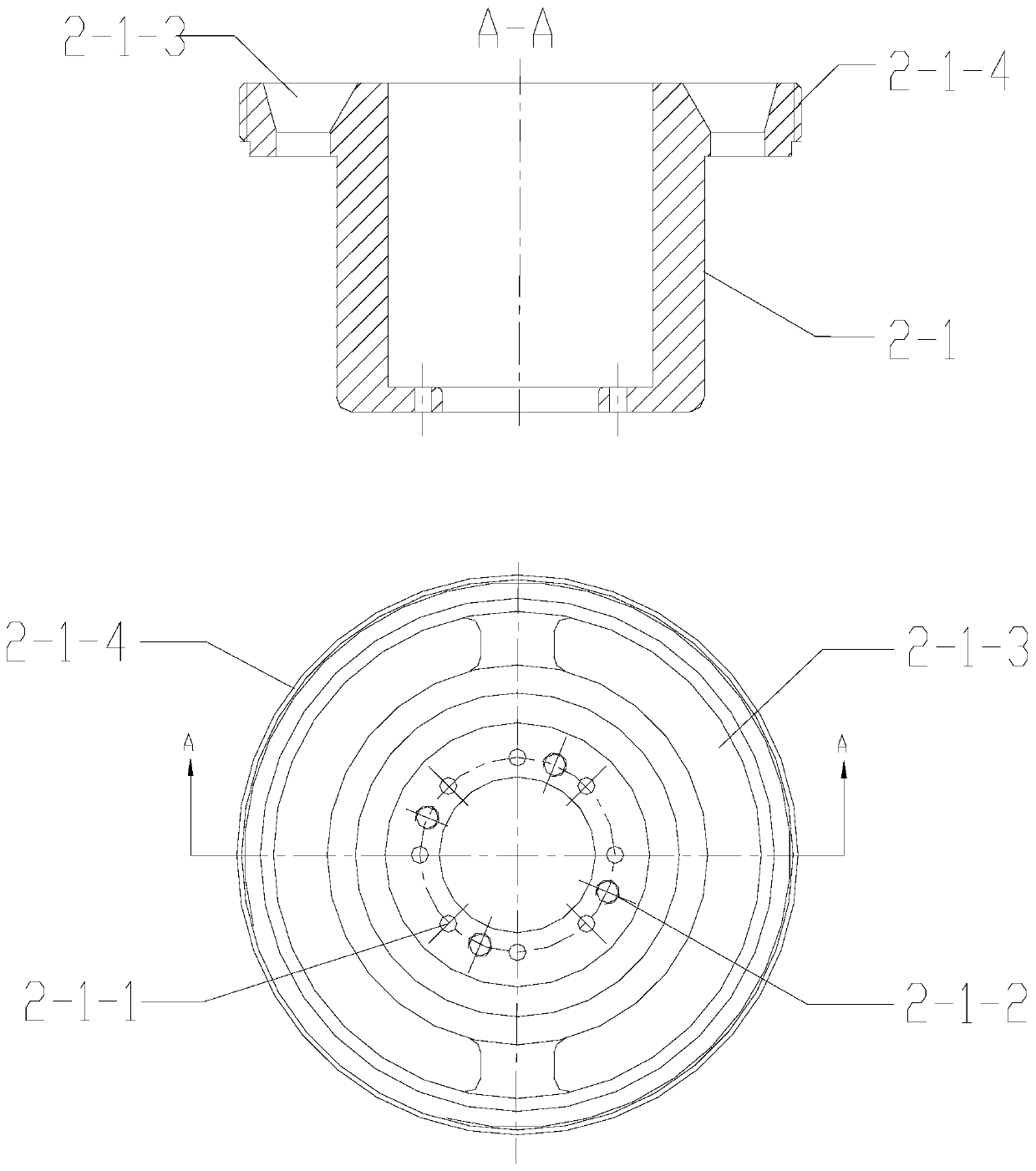

[0063] Such as Figure 6 As shown, the embedded warhead fuze chamber 1 is set on the positioning device 2 coated with anti-sticking coating, and connected and fixed by connecting screws 1-6. Before pouring the charge, the thread 2-1-4a on the step circumference of the upper mandrel 2-1 is matched with the thread above the charge surface of the warhead 1-7 body cavity, so that the pre-buried warhead fuze chamber 1 Locate at the specified position of the charge inner cavity 1-8, and then install the protective gear 1-10 above the end surface of the positioning device 2 in the body cavity, so as to prevent the slurry from polluting the thread of the body cavity during the charging process. 1. A protective cover 1-9 is installed on the upper end surface. The protective cover 1-9 can be made of rubber, polytetrafluoroethylene and other materials, and is fixed on th...

Embodiment 2

[0064] Embodiment 2: The inner cavity of the warhead 1-7 shell contains a closure above the charge surface

[0065] Such as Figure 7 As shown, the embedded warhead fuze chamber 1 is set on the positioning device 2 coated with anti-sticking coating, and connected and fixed by connecting screws 1-6. Before pouring the charge, the positioning platform 2-1-4b on the step circumference of the upper mandrel 2-1 cooperates with the closing end face of the warhead 1-7 projectile, so as to position the pre-buried warhead fuze chamber 1 in the charge Cavity 1-8 specifies the position, and then installs the protective cover 1-9 on the upper surface of the upper mandrel 2-1. The protective cover 1-9 can be made of rubber, polytetrafluoroethylene and other materials, and is clamped with the upper mandrel 2-1 It is fixed on the end face of the upper mandrel 2-1 by means of cooperation or threaded connection to prevent the slurry from entering the cavity of the upper mandrel 2-1, and final...

Embodiment 3

[0066] Embodiment 3: There is no thread 2-1-4a or closing above the charge surface of the warhead 1-7 body cavity

[0067] Such as Figure 8 As shown, the embedded warhead fuze chamber 1 is set on the positioning device 2 coated with anti-sticking coating, and connected and fixed by connecting screws 1-6. Before pouring the charge, the positioning platform 2-1-4b on the step circumference of the upper mandrel 2-1 cooperates with the rear end surface of the warhead 1-7 projectile, so as to position the pre-buried warhead fuze chamber 1 in the charge Cavity 1-8 specifies the position, and then installs the protective cover 1-9 on the upper surface of the upper mandrel 2-1. The protective cover 1-9 can be made of rubber, polytetrafluoroethylene and other materials, and is clamped with the upper mandrel 2-1 It is fixed on the end face of the upper mandrel 2-1 by means of cooperation or threaded connection to prevent the slurry from entering the cavity of the upper mandrel 2-1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com