A Direct Boost Double-fed Switched Reluctance Generator Converter System

A technology of switched reluctance and generator, which is applied in the direction of controlling the generator through the change of the magnetic field, controlling the generator, and controlling the system. The effect of low weight cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

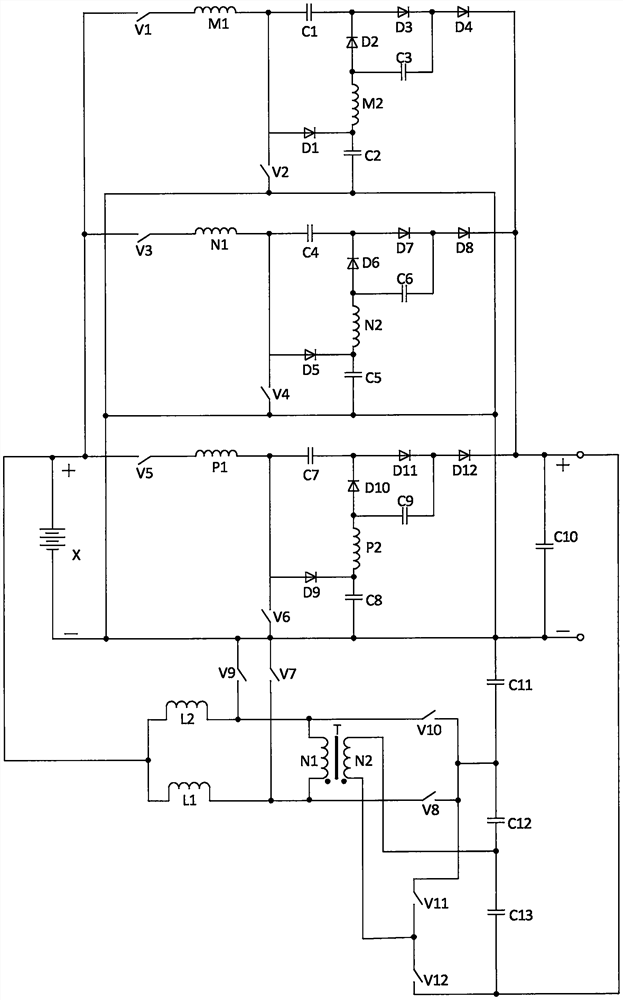

[0021] In this embodiment, a direct-boost double-fed switched reluctance generator converter system, the circuit structure of the converter system is as follows figure 1As shown, it consists of battery X, first switch tube V1, second switch tube V2, third switch tube V3, fourth switch tube V4, fifth switch tube V5, sixth switch tube V6, seventh switch tube V7, The eighth switching tube V8, the ninth switching tube V9, the tenth switching tube V10, the eleventh switching tube V11, the twelfth switching tube V12, the first winding M1 of the first phase winding, the second winding of the first phase winding M2, the first branch winding N1 of the second phase winding, the second branch winding N2 of the second phase winding, the first branch winding P1 of the third phase winding, the second branch winding P2 of the third phase winding, the first capacitor C1, the second capacitor C2, the third capacitor C3, the fourth capacitor C4, the fifth capacitor C5, the sixth capacitor C6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com