A multi-density adjustable charge structure and method for pre-splitting blasting

A pre-split blasting, multi-density technology, applied in blasting and other directions, can solve the problems of high requirements for transportation and storage of devices, unsecured safety, adjustment of charge density, etc. The effect of small human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

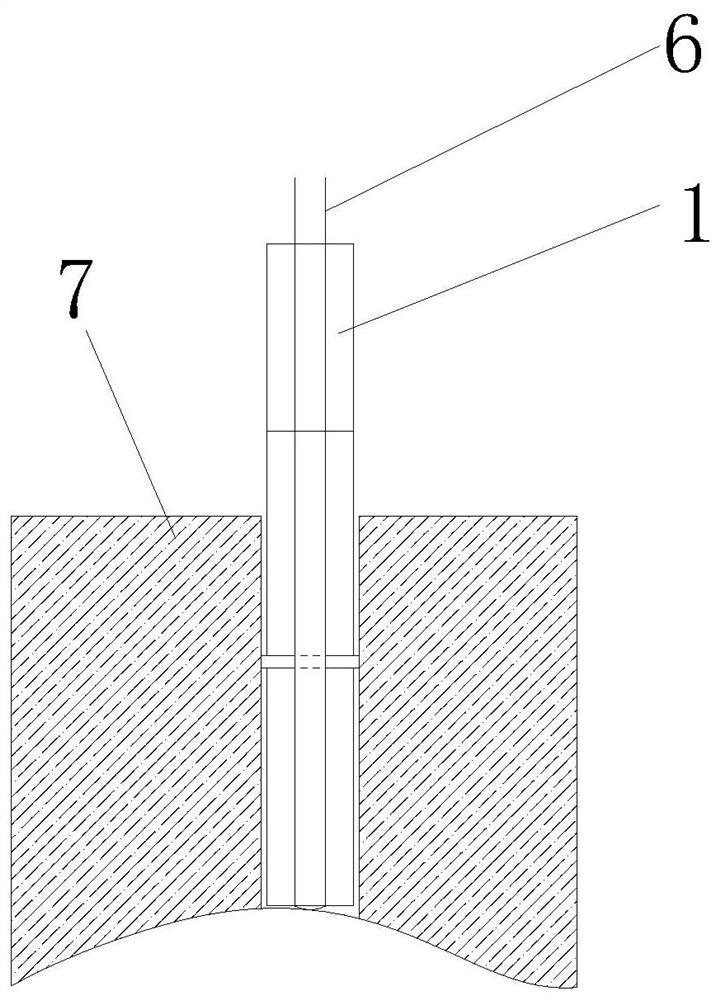

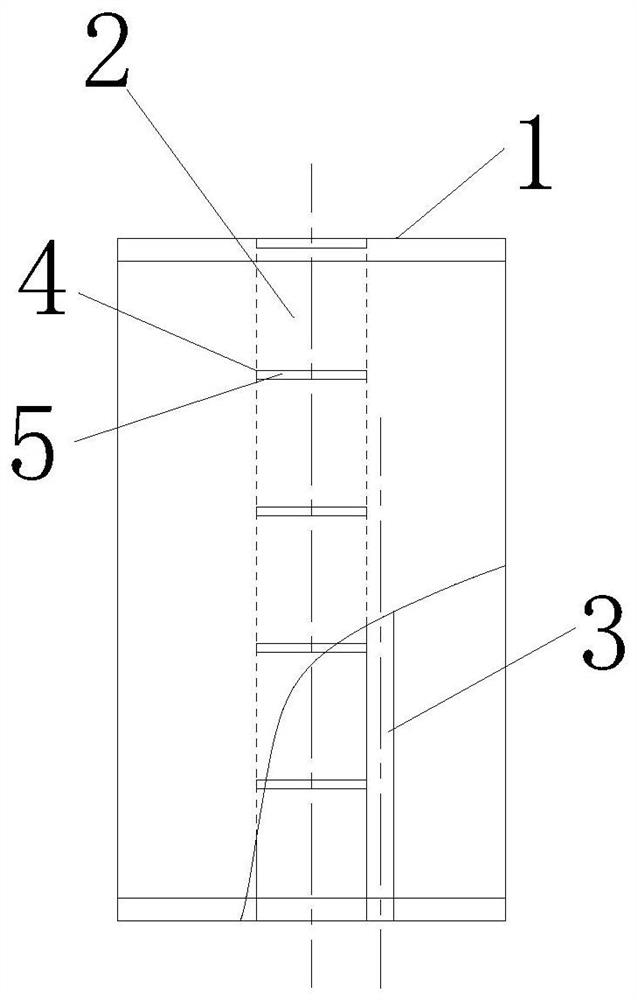

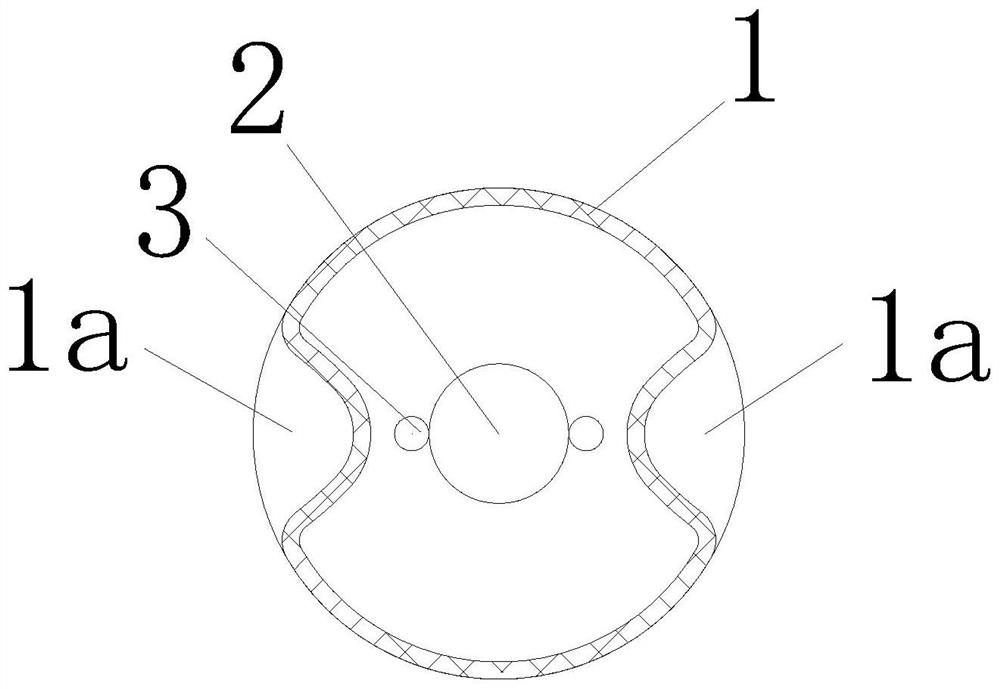

[0028] Such as Figure 1-3 As shown, a pre-splitting blasting multi-density adjustment charge structure is used to form an uncoupled charge structure in a blast hole, and is characterized in that it includes at least one standard cylinder 1, and the standard cylinder 1 has a cylinder at both ends Hollow structure at the bottom, and a through hole is formed on the bottom of the tube at one end; a charging tube 2 for charging is arranged in the standard tube 1, and the two ends of the charging tube 2 are connected with the two ends of the standard tube 1 Fittingly connected, and one end of the charge tube 2 is in communication with the through hole; the inner wall of the charge tube 2 is provided with a plurality of axially distributed annular grooves 4 for placing spacer plates 5; the standard The barrel 1 is provided with two detonating cord holes 3 parallel to and penetrating through the bottom of both ends of the standard barrel 1, and the two detonating cord holes 3 are sym...

Embodiment 2

[0037] Such as Figure 1-3 As shown, a pre-splitting blasting multi-density adjustment charging method adopts the pre-splitting blasting multi-density adjustment charging structure of embodiment 1 to carry out uncoupled charging, and the specific steps are:

[0038] (1) First select the standard cylinder 1 of appropriate specifications according to the diameter of the blast hole;

[0039] (2) Determine the amount of explosives in the standard cylinder 1 according to the linear charge density, fill the explosives in the charge tube 2, and use the partition plate 5 to space and seal, so that the explosives form a discontinuous distribution along the height direction of the standard cylinder 1;

[0040] (3) Pass both ends of a detonating cord 6 in the same direction through the two detonating cord holes 3 on the first standard cylinder 1, and lower the first standard cylinder 1 to the gun by lowering the detonating cord 6. the bottom of the hole;

[0041] (4) Continue to pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com